Carl Fisher

Member

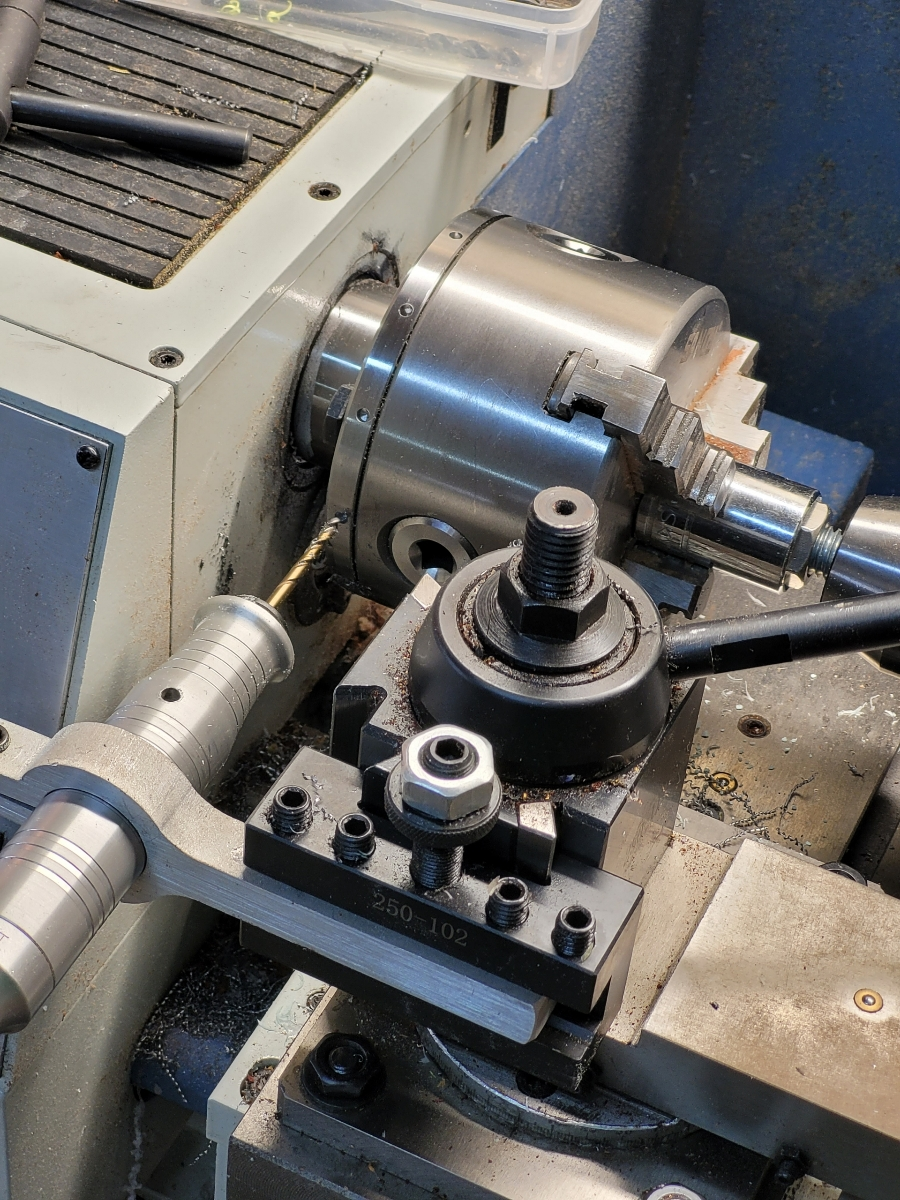

Happened across a fairly old post from skiprat showing use of a 12-point socket to index your chuck. Paired with my rotary tool holder is allowing me to add 24 index holes to my back plate so I can index 3, 4, 6, 8 or 12 sided facets. I'll add a removable bracket to the top with a spring loaded plunger to do the actual indexing.