SHIPPING RATES

If it's 16 ozs. or less and will fit into a 6x9 poly mailer...$5

Small Flat Rate Box... $8

99% of my orders will fit into those two categories.

If you order a rest over 10" or if your order is too large to fit in a Small Flat Rate Box then a Medium Flat Rate Box will be $15

INTERNATIONAL SHIPPING:

Before you order I'll need your address so I can calculate your shipping rate, you'll be charged exactly what it costs me.

Sometimes I get charged less than what I was quoted, in that case you'll get a refund for the difference.

______________________________________________

I want to THANK YOU for looking at my products, they're all made by me in my one man shop. All of these tools came about by my having a need for a custom tool and then making it for myself. I use these products every day and if they didn't work flawlessly I wouldn't offer them to you.

I don't have a website so if you want to place an order or if you have a question, PM me and we'll have a chat.

I also make "one off" tools so if you have an idea or a need for a "special" tool, give me a holler and we'll see what we can do.

---------------------------------------------------------------------------------------------------

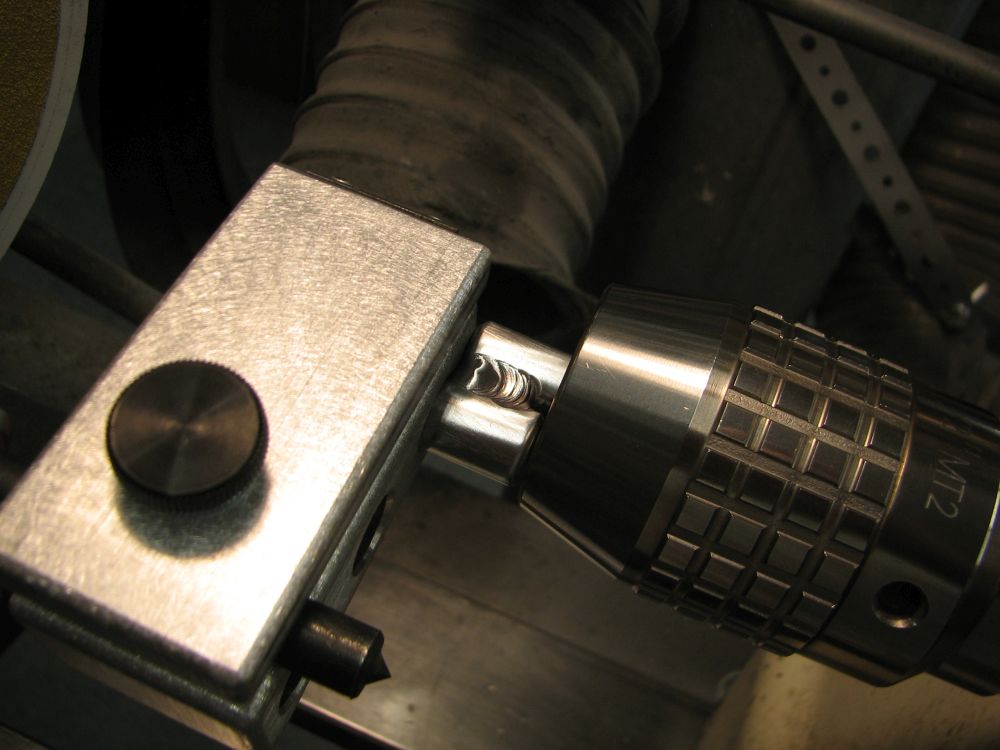

If you plan on buying a pin chuck, a pen mandrel or ANYTHING that fits in a collet chuck I would encourage you to watch this little video I made. Whenever you put ANY tool in a collet chuck you need to "dial it in" to make sure it's running true, this short video demonstrates how I do it...

"NEW PRODUCT"

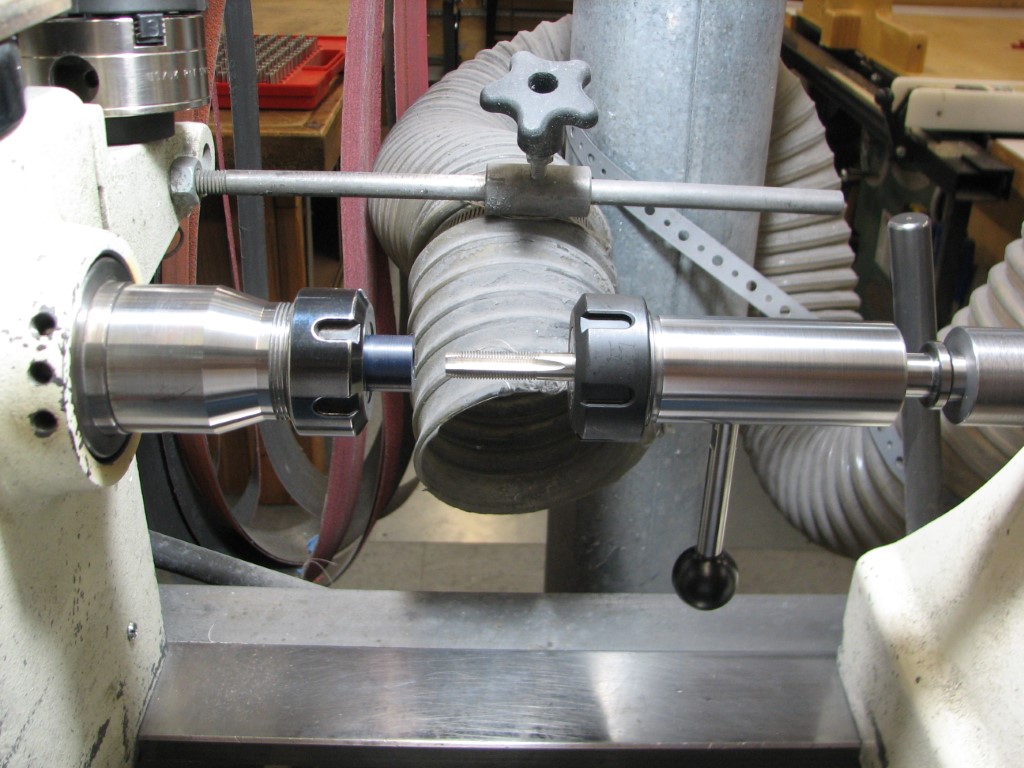

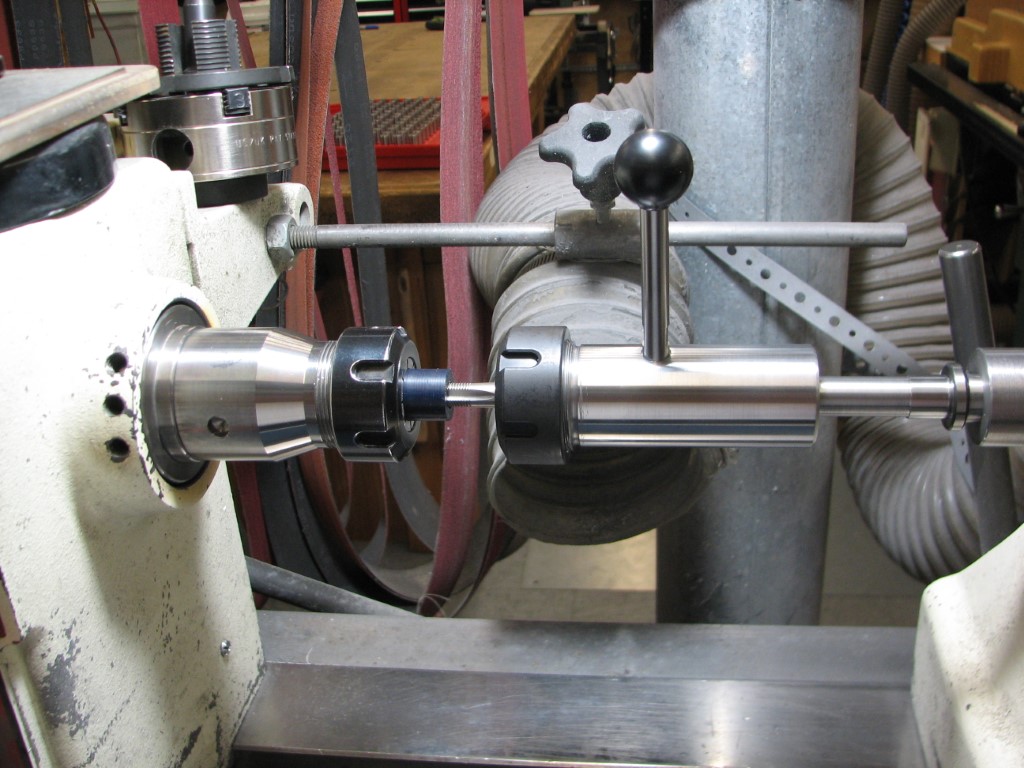

ER32 Sliding Tap and Die Holder.

No more dragging the tailstock when you power tap, just grab the handle and push the tap into the blank. When you reach the desired depth, stop the lathe and finish the last few threads by hand. If you have a shallow hole just use the handle and tap by hand, this holder has tremendous "feel" to it and makes hand tapping a real joy to do.

These take quite a few hours to make, I even make the ball on the handle from Delrin. I use a factory made MT arbor so it's a perfect fit for your tailstock. I keep #2mt arbors in stock but if you have a different size just let me know, same price for any size arbor.

Here are pics of the Die Holders, 1" on right and 1.5" on left. They have a 19mm stem so they will fit a 19mm or a 3/4" collet.

The Sliding er32 holder by itself is $100 plus shipping.

If you want the Sliding er32 holder plus the 1" and 1.5" die holders the price is $130, you save $10.

Individual die holders are $20 each.

If you already own one of my tap holders I'll give you the same discounted price of $30 for both die holders.

Step Drills

Pentel Pencil step drills are $20.

All other step drills are $15 labor plus the cost of the drill bit .

Here are some pics of Step Drills...

Most of my bits come from Brazil, there are quite a few American companies with factories there. Not all are from Brazil but I will never sell you one made in China.

All of my step drills are $15 plus the cost of the bit, I charge you exactly what I pay rounded up OR down to the nearest whole dollar.

We all know how fast prices are rising, the prices below are subject to change as prices rise.

PRICES UPDATED ON 8/14/23

Apollo...

23/64"...$21

29/64"...$22

BE ADVISED... If you are making the Apollo FOUNTAIN PEN you might need to drill a larger hole for the converter.

Artemis...

13/32"...$26

1/2"...$24

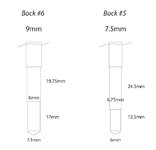

8mm Bock #5... $21

9mm Bock #6...$22

9mm Jowo #5...$22

9mm Jowo #6...$22

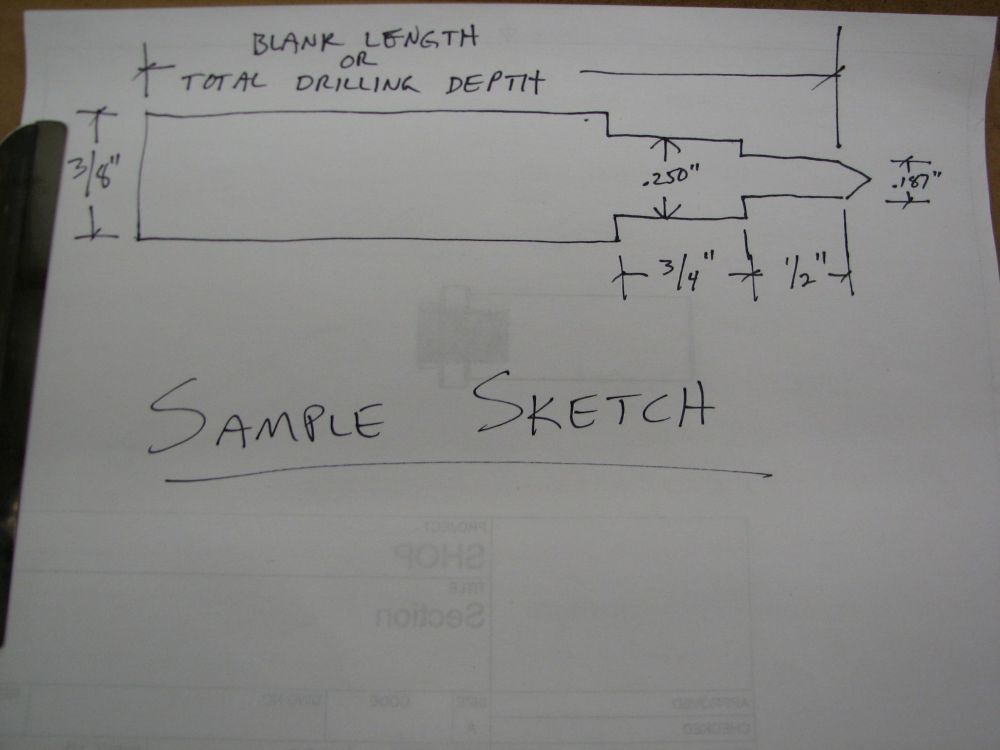

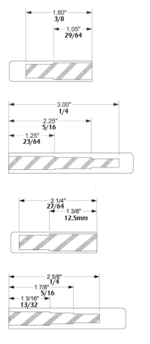

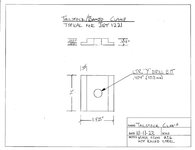

If you need a custom size just draw me a simple sketch like this...

PM me and we'll talk more about the specifics of your step drill bit.

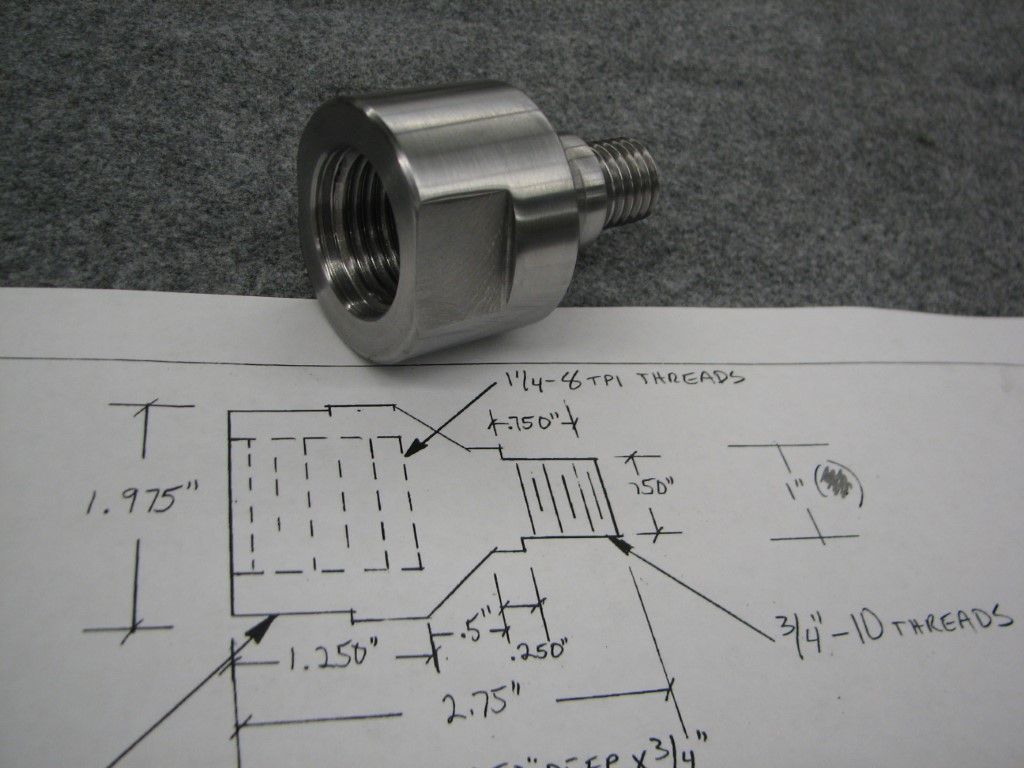

Spindle Adapters

If you need a spindle adapter for a common size try PSI or some other supplier first, they mass produce them and can sell them a lot cheaper.

The spindle adapters I make are the oddball/hard to find sizes. If you can't find what you're looking for elsewhere then you're in the right place.

I charge $35 for adapters up to 1 1/4"-8tpi, anything larger than that will depend on steel prices but a good guess would be in the $50 range. I'll quote you a price based on current steel prices.

These two are 1 3/4"-8tpi internal threads to 1 1/4" and 1"-8tpi external threads...

Here are some other assorted sizes...

Would you like to turn your wood lathe into a tool grinder?

Take a look at this nifty Spindle Adapter, this particular one fits a 1"x8tpi spindle nose and has a 5/8" mounting stud that will accept a grinding wheel...

I can make you one to fit any size lathe and grinding wheel.

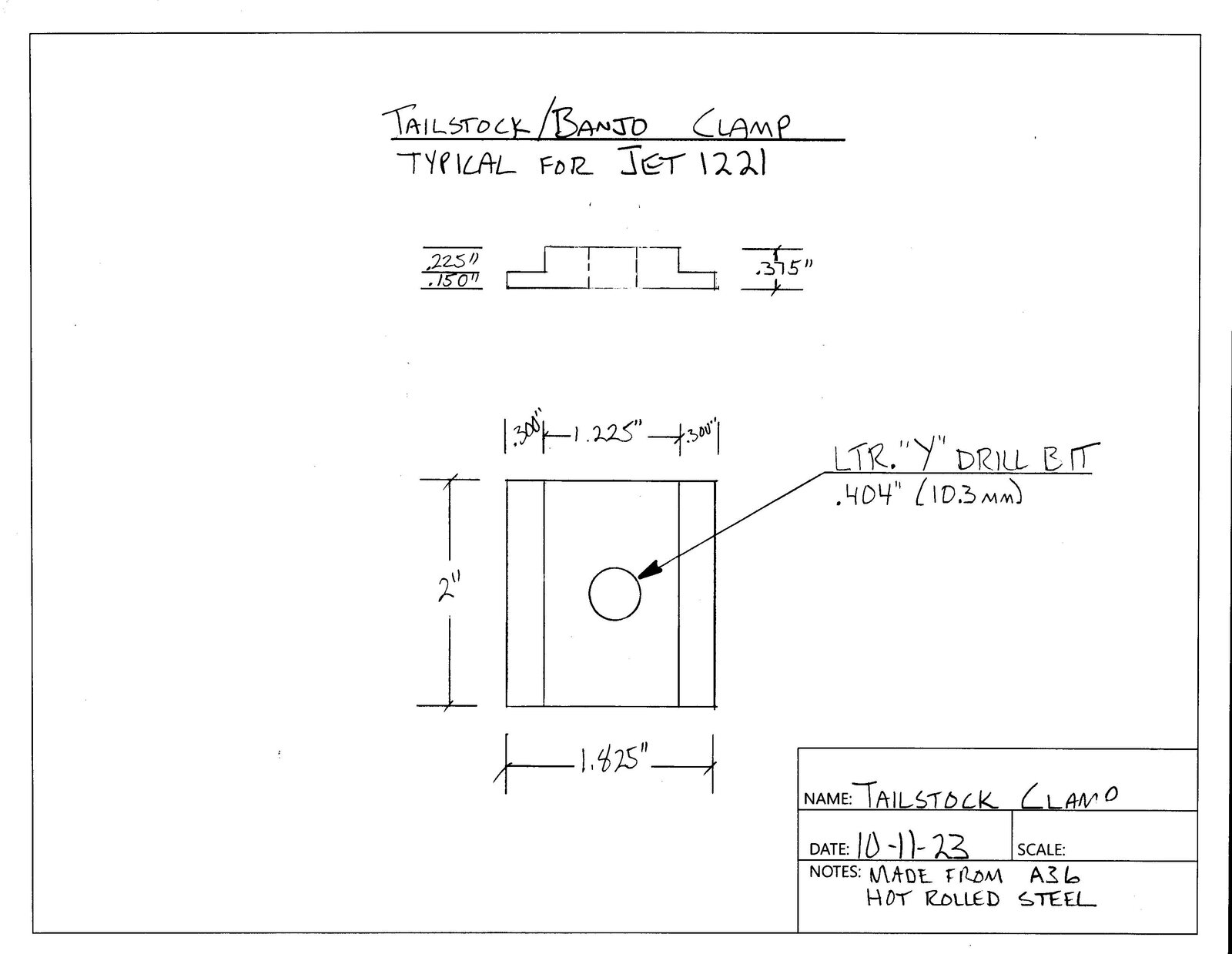

TAILSTOCK / BANJO CLAMP

If you're having trouble with your tail stock or banjo slipping under pressure then this will most likely fix your problem. I've also been told by more than a few people that it also helped with their tailstock/headstock alignment issues.

They're made from 3/8" thick steel and are a lot stronger than the round ones, here are some pics of a typical one...

(click photo to enlarge)

This drawing is for the Jet 1221 which fits quite a few of the small lathes.

If this size doesn't work for your lathe give me the two measurements listed below and I'll custom make one for you.

Measurements needed are...

1- Distance between ways.

2- Diameter of bolt that goes through the center.

The price is only $15-plus shipping... WHAT A DEAL!!!

__________________________________________________________________

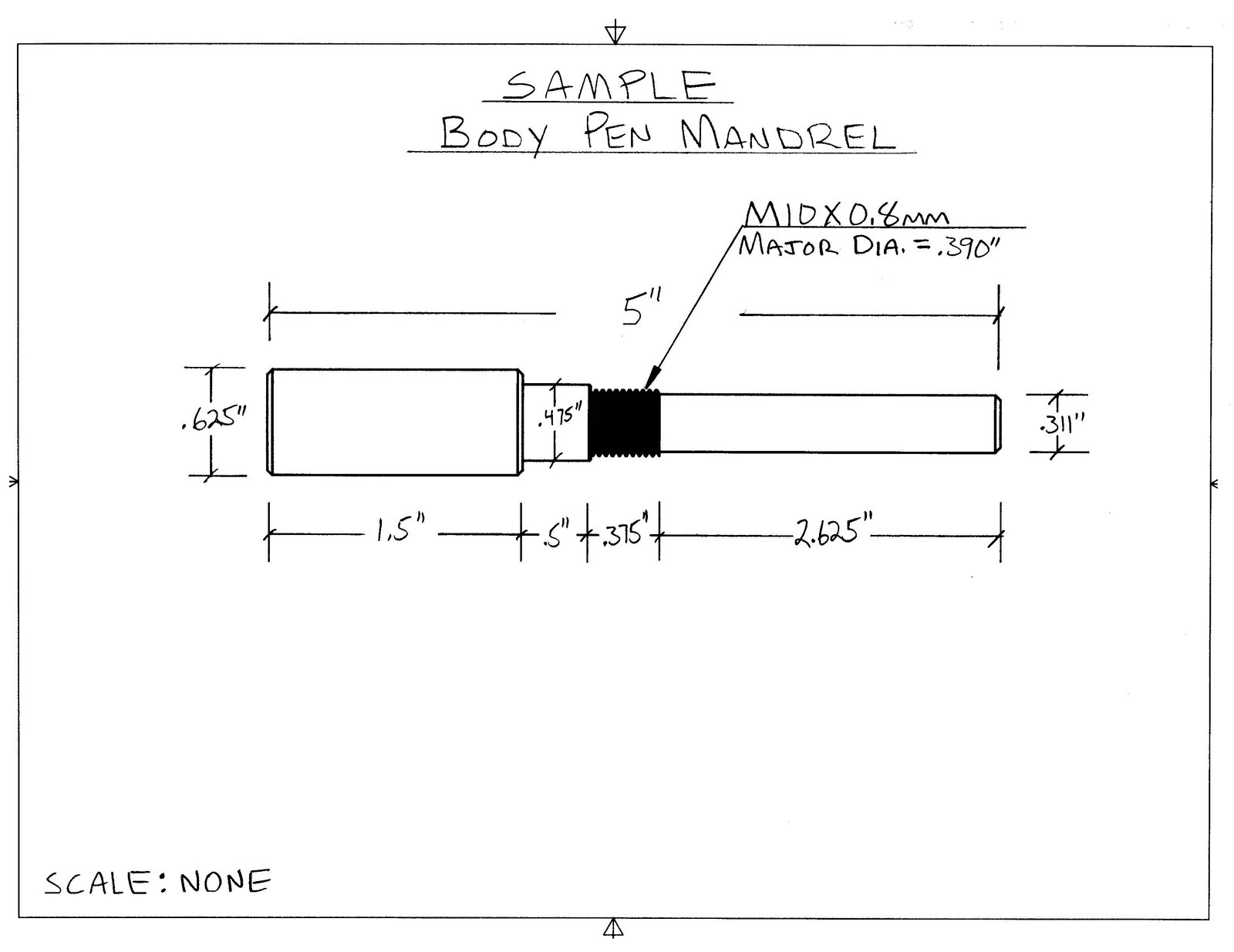

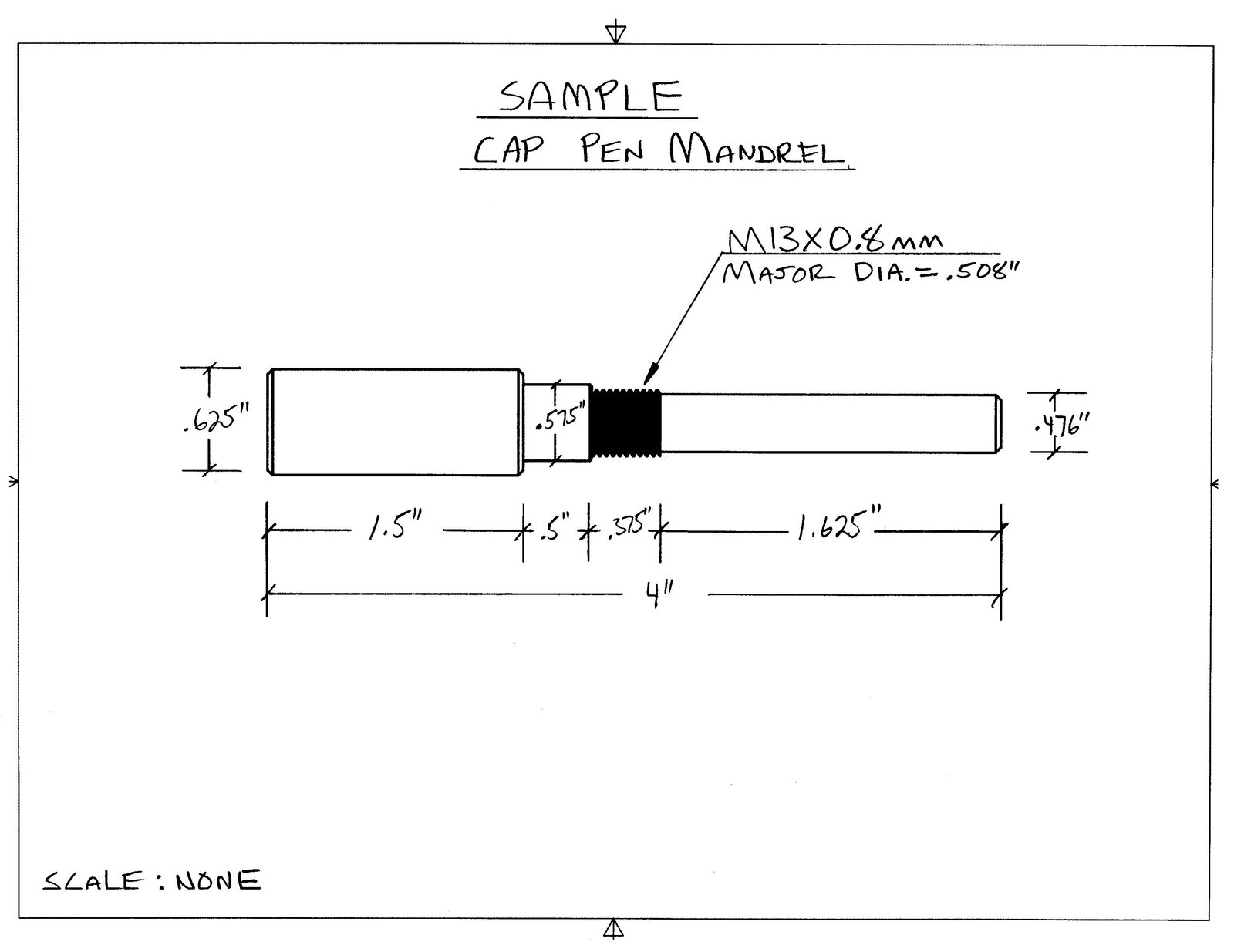

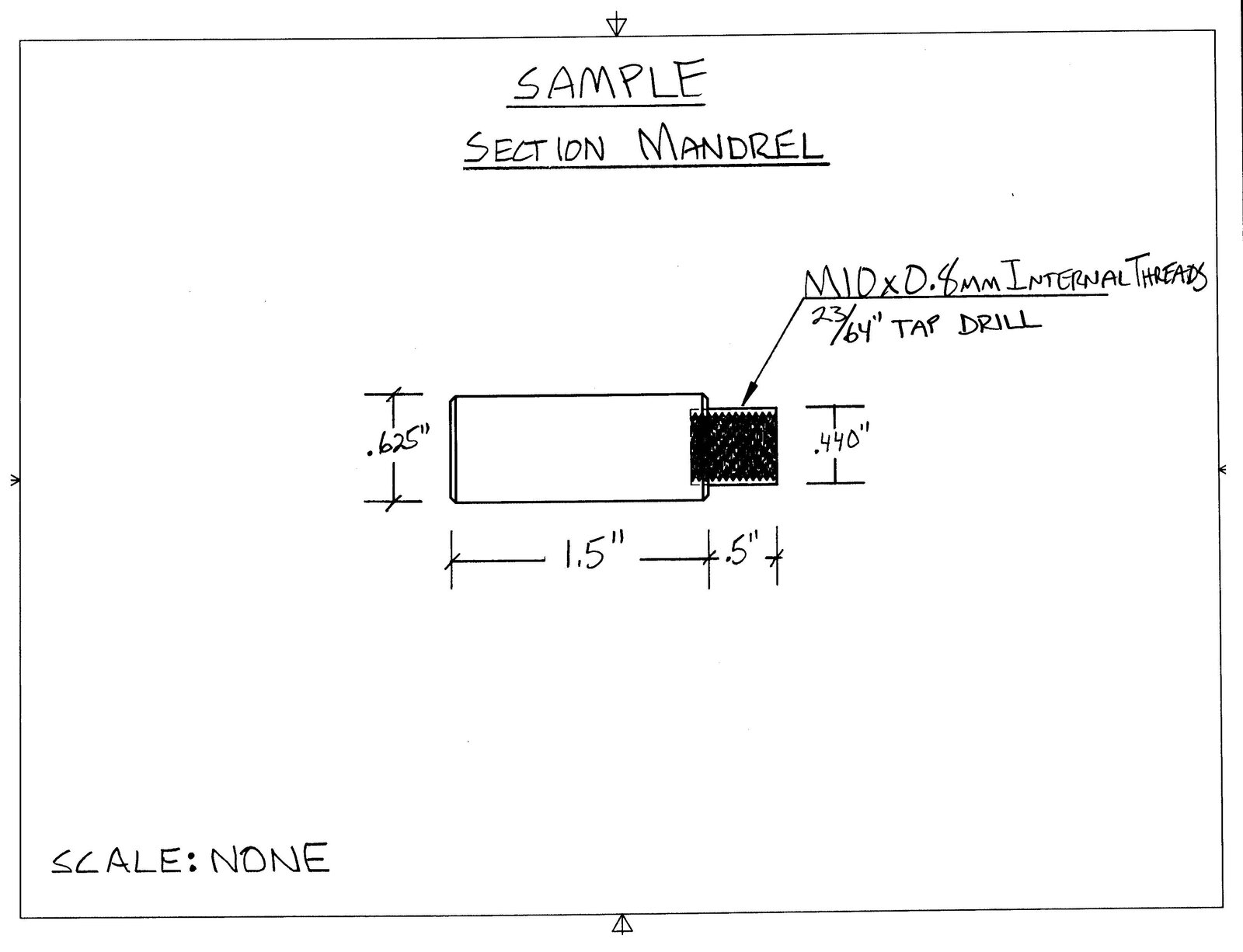

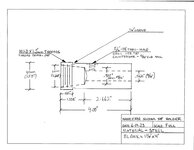

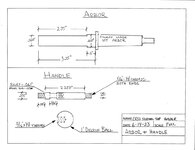

Custom threaded mandrels for fountain pens...ONLY $20 each

You'll need to send me the die you use and a drilled and tapped blank for each size, both will be returned unharmed.

Pen taps are varied and expensive so I can't afford to have them all, I need the drilled and tapped blank so I can custom fit the mandrel.

If you order a complete 3 piece set (Cap, Body and Section) the price will be $50, that's a $10 discount!

All my mandrels are made to fit a 5/8" (16mm) collet, if you want a different size let me know.

(click photo to enlarge)

Here are some sample drawings of a typical set of mandrels...

____________________________________________________________________________________________________________________________________

1 1/2" die holder adapter that fits in the LMS 1" die holder...$20 each

The die holder adapter in these photos is made from steel, the one you'll get will be aluminum.

I can also make a custom sized holder for any size die you have.

This product is the 1 1/2" adapter ONLY, you will need the Little Machine Shop die holder in order to use my adapter. Here's the link...

https://littlemachineshop.com/products/product_view.php?ProductID=2314&category=

(click photo to enlarge)

_________________________________________________________________________________________________________________________

OFFSET SANDING JIG

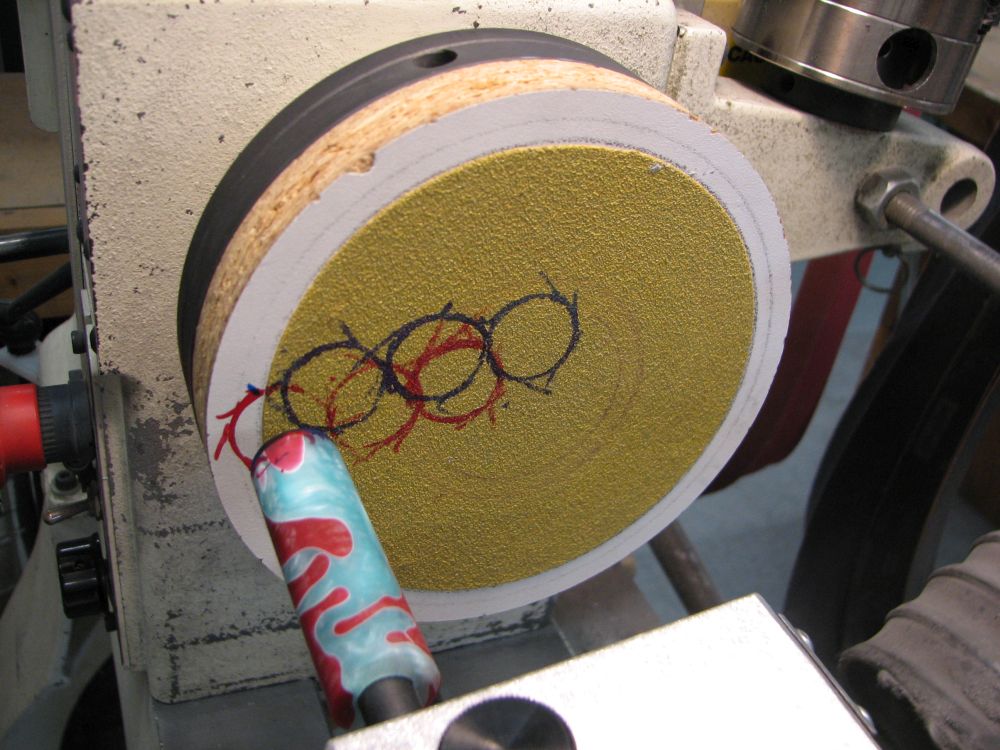

This tool, along with three other tools that you most likely already have, allows you to turn your lathe into a 5" disc sander.

We've all sanded on our lathe like this.....

(click photo to enlarge)

The problem with this method is you only use the center of the paper and it still really doesn't work that well.

This tool allows you to OFFSET the blank, which allows you to use the WHOLE disc.

It has 3 different positions that allow you to move to a new spot whenever you want. The V-groove holds a transfer punch and the handle tightens everything down. To use it you just hold even downward pressure on the blank and push it into the disc...REAL simple!

If you don't want to use transfer punches you can put a regular pen mandrel in it and use your tube sleeves to take up the slack.

You can even use my Sanding Mill if you already have one of those.

You'll get the jig and a 1/2" steel bar that fits in your tail stock drill chuck. The steel bar has a flat spot milled in it which allows you to tighten the set screw securely.

WARNING: Do not over tighten the thumbscrew, the plastic cap is pressed on and could come loose.

(click photo to enlarge)

The other three things you'll need are a disc, a set of transfer punches and a 1/2" drill chuck. If you purchased your lathe new it most likely came with a FACE PLATE which you can turn into the sanding disc, if not you can buy them just about anywhere for very little.

If you want a more precise method of holding the blank than transfer punches, how about using my PIN CHUCKS. They're an EXACT fit for your tube and can also be used for CLOSED END turning.

Two uses for the price of one!!

I DON'T SELL THESE THREE THINGS....YOU NEED TO PURCHASE THEM ELSEWHERE!

(click photo to enlarge)

I made my disc out of shelving material that has Formica on it, the Formica works well with the "sticky" discs. I don't recommend the hook and loop discs, they're too soft.

The price for this jig is only $40

THANKS FOR LOOKING!

WAIT...LOOK AT THIS!

One of our fellow members, Mack Cameron (Mack C.) emailed me and asked if I could make an adapter that would fit the morse taper driver of a standard pen mandrel. It sounded like a good idea so I made one to see if it would work...AND IT DOES!

This is what I came up with...

(click photo to enlarge)

What this does is eliminate the need for a drill chuck, so if you don't have a drill chuck then this might be just the ticket!

It has 1/4"-28 threads on it and the other end fits in the jig like the regular 1/2" rod does.

Your order WILL NOT include the MT DRIVER, just the adapter that screws into it.

Here's a link to the MT DRIVER from EXOTIC BLANKS... https://www.exoticblanks.com/morse-taper-driver-arbor-choose-size.html

NOTE: Be sure your morse taper part has 1/4"x28tpi threads, some are METRIC!

If you want this adapter add $5 to the price of the jig.

_______________________________________________________________________________________________________

OFFSET MOUNT

This little device "offsets" the sanding jig by 1/2" and allows you to use a 6" sanding disk. It also uses the "in between" spaces the straight mount doesn't get.

In this photo the RED circles are made with the new "Offset Mount" and the BLUE circles are made with the standard straight mount.

The photo shows a 5" sanding disc mounted on a 6" faceplate...

Here are more pics of the new mount...

The price is $10 each.

Thanks for looking!

TOOL RESTS

These are made from W-1 precision ground tool steel, the shiny stuff, so your turning tools will just glide over the surface.

They are VERY high quality, anybody that's familiar with my products knows that. They all come with a money back guarantee. If FOR ANY REASON you're not happy with it, send it back and I'll return your money, plus shipping, NO QUESTIONS ASKED.

They all come with a brass trim ring and have flats ground in them so you can tighten it with a wrench. This makes for a "modular" system, if you wish you can buy several different length rests and interchange them on the same post.

These tool posts are made of W-1 tool steel which is rust "resistant" NOT rust "proof". If your shop is a high humidity environment then a light coat of wax will help prevent rust.

Post prices are.......

5/8" and smaller...$25

Larger than 5/8"...$35

I stock up to 1" material so we need to talk if you want a post larger than 1".

NOTICE: If you order a 1" post... PLEASE CHECK THE DIAMETER WITH CALIPERS! Some posts are 25mm which is REAL close, but a 1" post won't fit a 25mm banjo.

Rests, UP TO 12", will be $10ea. ADD $1 PER INCH to any rest over 12".

PLEASE NOTE: 9" is the longest length I recommend for a 5/8" post, 12" for a 25mm or 1" post. Having said that I WILL make you any length you want.

As you can see from the prices, this is not some get rich scheme. I'm doing this as a service to my fellow IAP members and frankly, it will give me something to do!!

I encourage you, before you order, to go out to your lathe and be sure of the length you want. I personally like 3.25" for turning one blank at a time between centers, I also sell quite a few 4". That's the beauty of this, it's not a "one size fits all" deal.

Besides the lengths of the rests you want, I'll need two measurements from you... the TOTAL height (post plus rest, just measure your factory rest from TOP to BOTTOM), and the diameter of the post.

Here's a sample of the "height" measurement I need...

(click photo to enlarge)

This one is 6 1/4", yours will probably be different

I take PayPal and personal checks. PM me and I'll send you my PayPal address.

THANK YOU!!!

________________________________________________________________________________________________________________________________________________

FLAT TOP TOOL RESTS

I had a customer request one of these to use with his carbide turning tool and he liked it so much I decided to add it to my inventory.

I don't have a carbide tool...YET!...but I'm told the flat top rest works well with the flat bottom of the tool, giving you more control.

I designed them to fit my standard tool posts so if you have one of mine then these will fit, the only difference is the diameter.

Since the threaded hole in my standard round tool rest is only .125" from the surface I made these "flat" ones .125" bigger. If you have a 5/8" round post then you need to order a 3/4" "flat top" rest, if you have a 1" or 25mm post you'll need to order a 7/8" "flat top" rest.

Since I remove .125" of material to form the flat, THE HEIGHT WILL REMAIN THE SAME, it will just be a tad wider which isn't a problem.

The price for the 3/4" flat top rest is $20.

The price for the 7/8" flat top rest is $25.

PM me and I'll give you my PayPal address.

THANK YOU

_____________________________________________________________________________________________________________________________________________

TOOL POST STOP COLLARS

These STOP COLLARS are designed to keep your tool post at the same height EVERY TIME you use it, no more fumbling around to get it set at the right height, with these you just set it and forget it!

(click photo to enlarge)

They're made from aluminum and have 3 BRASS TIPPED set screws, the brass won't ding up your post like a standard steel one will.

They hold tight and use a 3/32" Allen wrench to tighten.

I can make them ANY size you want but I'm going to stock 5/8"and 1", those are by far the most common.

PLEASE check the diameter of your post with calipers before ordering.

Price is $10 ea.

The price is the same no matter what size you order.

_______________________________________________________________________________________________________

SHOPSMITH TOOL POSTS

Now all of you ShopSmith owners can use any of my custom rests when you

purchase one of these slick new posts...

This shows it with one of my Flat Top rests attached...NOT INCLUDED.

(click photo to enlarge)

Here it is by itself...

You'll get the post and the brass trim ring for only $35, that's a STEAL considering how much machining is involved!:biggrin:

PM me with your order and I'll give you my PayPal address.

THANK YOU

___________________________________________________________________________________________________________________________________

Dial Indicator Posts

and Adapters

In my opinion, everyone who owns a lathe needs a dial indicator. They're invaluable for making sure WHATEVER you have chucked in your lathe is running true. Probably the most common use for penturners is to check the run out on a pen mandrel...

(click photo to enlarge)

Another one I use a lot is checking the run out on a pin chuck...

WHATEVER you turn will benefit from making sure that it's "running true".

With that in mind I designed an economical way to attach a dial indicator to one of my "Custom Tool Rests"...

This shows the two most common sizes, the one on the left has 1/2" threads and fits a 1" post, the one on the right has 3/8" threads and fits on a 5/8" post.

Here it is with the DI installed but before it gets screwed onto the post...

Here it is screwed onto my 1" post...

All I need from you is the thread size of your post. The cap screw is INCLUDED and takes a 3/16" allen wrench.

As with all my custom made tools, these are economically priced to be affordable to everyone... $10 ea.

For those of you that don't have one of my tool rests or for those that would like a DEDICATED DI holder( which I highly recommend) I designed this...

I can make them any size, just measure the diameter of you factory rest. I'll also need the distance from the TOP of your banjo to the CENTER LINE of your lathe.

Here's a photo of the measurement I need, 4" on my lathe.

(click photo to enlarge)

As you can see in the photo, these are made from aluminum and have a "stop" on them. That stop enables you to SET IT AND FORGET IT! Every time you grab it it will be set to the correct height, that's a real nice feature. I need that banjo/center line dimension to make sure the stop is in the right position. It has about 1/2" of adjustment in it so when you get it you just set it once and...FORGET IT!

The stop is milled to the radius of the post to make it more functional and to give it a cleaner look.

All the screws are included, you'll need a 3/16" allen wrench for the DI and a 9/64" for the stop.

The dial indicator is NOT provided, that's something you will have to buy yourself.

I recommend a standard AGD GROUP 2 DI with a 2 1/4" dial and 1" of travel.

BE SURE TO ORDER THE INDICATOR WITH A LUG BACK, you need the lug to be able to bolt it to the holder.

Here's one at Amazon ...1" Dial Indicator

The price for my DEDICATED DI POST is only $20!

____________________________________________________________________________________________________________________________________________________

PIN CHUCKS

See my video on how get rid of the runout on your Pin Chuck... Pin Chuck Video

These pin chucks are custom made for any size pen you want to make, most folks use them to make "closed end" pens but they can be used for ANYTHING with a hole in it that you want to turn on a lathe.

They're made from the same tool steel as my TOOL RESTS and will last forever....IF you take reasonable care of them!

They are approx. 4" long and have a 1/8" pin that fits in an 5/8" long slot. The turned down part that fits inside the tube is about 1/2" longer than the tube so you have some room to work on the end of your blank.

The little "dimple" you see is a reference mark so when you're done and want to remove the blank, you turn the chuck so the dimple is on top, that way the pin won't fall on the floor and roll under something........can you say ..." Murphy's Law"?

All my standard PIN CHUCKS are made from 1/2" material and will fit either a 1/2" or 13mm collet. My 7mm PIN CHUCKS fit a 1/4" or 7mm collet. If you need a PIN CHUCK larger than 1/2" I'll let you know what size collet you'll need.

I have a lot of different pen kits in stock but I don't have them all. If you want a pin chuck to fit something I don't have I'll either order that size tube OR you can send me the tubes and I'll return them with your order. Measuring the I.D. of tubes with calipers is fine for some applications but not for this, I like to have the tubes I'm fitting on hand so I can insure a perfect fit.

This is the pin chuck mounted in a collet chuck, ready to accept a blank.

This shows a sample that I turned down to a pen cap shape....works like a charm!

Pin chucks are "tube specific" so you'll need TWO pin chucks to do both halves of a pen.

These little guys are only$17 ea. , no matter what size you want!

PM me and I'll give you my PayPal address.

_________________________________________________________________________________________________________

SANDING MILL 2.0

This is my new version of an old tool....

(click photo to enlarge)

I had some requests for a sanding mill that had TWO flat and true sides so folks could use the short side for smaller stuff.

I also wanted a simpler way to make them.......

The old way with wood, brass and glue took WAY too long to make, consequently I had to charge what I thought was a little too much. With this new design not only will you be getting a better product, you'll be paying LESS for it, how often does that happen?!

THIS TOOL DOES THE SAME JOB AS THE OLDER MODEL SO IF YOU ALREADY HAVE THE OLDER VERSION YOU DON'T NEED THIS ONE.

(Unless of course you really want one!:biggrin

This new version does NOT include sandpaper or punch!

To make the discs get some sticky backed sandpaper and cut it into small squares, I use the 5" round discs made for an orbital sander. A regular notebook paper punch will punch a perfectly sized hole for the shaft.

I use 100 grit for mine but experiment and see what's right FOR YOU!

Here's a photo of the sanding mill....

The price for the new model is ONLY $20!

This part shows my old style mill but the process is the same with the new one....

Here's a photo with one of my sleeves installed. The rod on the mill is the same size as your standard "A" penturners mandrel so you can make sleeves from a slimline tube if you like.

The one in the photo is made out of Delrin to fit a Sierra style pen tube...

Here it is with the Sierra barrel attached and ready to go...

I use mine at about 1,000 rpm and just push real lightly, it's really easy to use and you'll get the hang of it right away!

If you don't want to make your own sleeves I charge $5 each for sleeves that are an exact fit for the tube.

PLEASE note that this is a FINISHING tool, it's meant to be used on already turned barrels and really excels at removing CA and squaring things up prior to assembly. You'll be amazed at how much better everything fits after using this tool.

See my OFFSET LATHE SANDING JIG if you need a more aggressive tool.

--------------------------------------------------------------------------------------------------------------------------

17pc. SET of TUBE SLEEVES

These sleeves are NOT an exact fit like the ones I offer above, these are the same sizes as a set of transfer punches. These are made from wood, I try and get them to the exact size marked on them but that's next to impossible. The exact number isn't important, the idea is to pick the largest one that will fit inside your tube.

These are used the same way the transfer punches are used for my OFFSET SANDING JIG, you need to use a slight downward pressure when using them. While they are not an exact fit there is approx. .015" between sleeves so the one you choose will be REAL close. Tolerance on sleeves...+/- .005"

The price for 17 sleeves AND this nifty little stand made from MDF is only $50. That's a $35 savings on the sleeves and the stand is FREE!

BUT WAIT..........CHECK OUT THIS DEAL!!!!!!

For only $60 I'll include one of my SANDING MILLS!!

That means you get the SANDING MILL for ONLY $10, WHAT A DEAL!!!!

Thanks for looking!

---------------------------------------------------------------

Straight Shank Dead Centers

I made one of these for Mike (navycop) who has a Shopsmith and he wanted to turn between centers with custom bushings. The Shopsmith doesn't have a Morse taper so he needed a center with NO taper that he could mount in his drill chuck.

Afterwards I got to thinking...I'll bet these would work great for those of us with Beall or other brands of collet chucks who are tired of removing the chuck so we can insert our Morse taper dead center into our headstock and turn between centers.

The one in the photo is 1/2" X 3" but I can make them ANY diameter and ANY length you want. They are STRAIGHT, i.e. NO TAPER, and have a standard 60 degree end. They're made from the same high quality tool steel as my Custom Tool Rests.

I harden them by heating the tip to a cherry red and quickly plunging it into cold water, I tried to turn one on my metal lathe AFTER it was hardened and I dulled my HSS cutter so I know it's hard enough for TBC.

I'm asking $12 each...ANY DIAMETER, ANY LENGTH UP TO 6", $1 per inch after that.

PM me and we'll discuss your needs and I'll give you my PayPal address for payment.

THANK YOU!

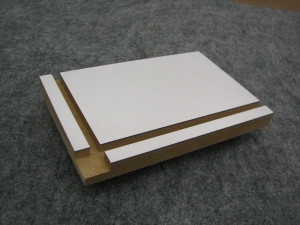

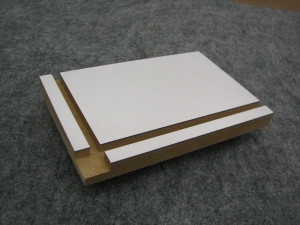

Lathe Sanding Table

NOTICE : This table is NOT for squaring blanks to the tube, see my OFFSET LATHE SANDING JIG for that.

This is the answer for all of you who would like a disc sander but don't have the room or the budget for a stand alone model. I designed it to screw on to my tool posts so if you already have one you're all set, if not then you will need to order a post to make it work.

It's made from 1/2" MDF for flatness and stability and is covered with authentic Formica for a smooth surface and a lifetime of use. It also has a 1/4" x 1/4" channel routed on two sides so you can make your own fences.

The mounting block is made from 5/8" thick solid aluminum.

If you need a post I'll discount it $5 if you buy the post and table together.

The price for the table only is $25-plus shipping.

Table plus 5/8" post...$45-plus shipping

Table plus 1" post...$55- plus shipping.

You need to make your own fences, I won't be offering them for sale. I just used scrap wood and CA glued it together.

If it's 16 ozs. or less and will fit into a 6x9 poly mailer...$5

Small Flat Rate Box... $8

99% of my orders will fit into those two categories.

If you order a rest over 10" or if your order is too large to fit in a Small Flat Rate Box then a Medium Flat Rate Box will be $15

INTERNATIONAL SHIPPING:

Before you order I'll need your address so I can calculate your shipping rate, you'll be charged exactly what it costs me.

Sometimes I get charged less than what I was quoted, in that case you'll get a refund for the difference.

______________________________________________

I want to THANK YOU for looking at my products, they're all made by me in my one man shop. All of these tools came about by my having a need for a custom tool and then making it for myself. I use these products every day and if they didn't work flawlessly I wouldn't offer them to you.

I don't have a website so if you want to place an order or if you have a question, PM me and we'll have a chat.

I also make "one off" tools so if you have an idea or a need for a "special" tool, give me a holler and we'll see what we can do.

---------------------------------------------------------------------------------------------------

If you plan on buying a pin chuck, a pen mandrel or ANYTHING that fits in a collet chuck I would encourage you to watch this little video I made. Whenever you put ANY tool in a collet chuck you need to "dial it in" to make sure it's running true, this short video demonstrates how I do it...

"NEW PRODUCT"

ER32 Sliding Tap and Die Holder.

No more dragging the tailstock when you power tap, just grab the handle and push the tap into the blank. When you reach the desired depth, stop the lathe and finish the last few threads by hand. If you have a shallow hole just use the handle and tap by hand, this holder has tremendous "feel" to it and makes hand tapping a real joy to do.

These take quite a few hours to make, I even make the ball on the handle from Delrin. I use a factory made MT arbor so it's a perfect fit for your tailstock. I keep #2mt arbors in stock but if you have a different size just let me know, same price for any size arbor.

Here are pics of the Die Holders, 1" on right and 1.5" on left. They have a 19mm stem so they will fit a 19mm or a 3/4" collet.

The Sliding er32 holder by itself is $100 plus shipping.

If you want the Sliding er32 holder plus the 1" and 1.5" die holders the price is $130, you save $10.

Individual die holders are $20 each.

If you already own one of my tap holders I'll give you the same discounted price of $30 for both die holders.

Step Drills

Pentel Pencil step drills are $20.

All other step drills are $15 labor plus the cost of the drill bit .

Here are some pics of Step Drills...

Most of my bits come from Brazil, there are quite a few American companies with factories there. Not all are from Brazil but I will never sell you one made in China.

All of my step drills are $15 plus the cost of the bit, I charge you exactly what I pay rounded up OR down to the nearest whole dollar.

We all know how fast prices are rising, the prices below are subject to change as prices rise.

PRICES UPDATED ON 8/14/23

Apollo...

23/64"...$21

29/64"...$22

BE ADVISED... If you are making the Apollo FOUNTAIN PEN you might need to drill a larger hole for the converter.

Artemis...

13/32"...$26

1/2"...$24

8mm Bock #5... $21

9mm Bock #6...$22

9mm Jowo #5...$22

9mm Jowo #6...$22

If you need a custom size just draw me a simple sketch like this...

PM me and we'll talk more about the specifics of your step drill bit.

Spindle Adapters

If you need a spindle adapter for a common size try PSI or some other supplier first, they mass produce them and can sell them a lot cheaper.

The spindle adapters I make are the oddball/hard to find sizes. If you can't find what you're looking for elsewhere then you're in the right place.

I charge $35 for adapters up to 1 1/4"-8tpi, anything larger than that will depend on steel prices but a good guess would be in the $50 range. I'll quote you a price based on current steel prices.

These two are 1 3/4"-8tpi internal threads to 1 1/4" and 1"-8tpi external threads...

Here are some other assorted sizes...

Would you like to turn your wood lathe into a tool grinder?

Take a look at this nifty Spindle Adapter, this particular one fits a 1"x8tpi spindle nose and has a 5/8" mounting stud that will accept a grinding wheel...

I can make you one to fit any size lathe and grinding wheel.

TAILSTOCK / BANJO CLAMP

If you're having trouble with your tail stock or banjo slipping under pressure then this will most likely fix your problem. I've also been told by more than a few people that it also helped with their tailstock/headstock alignment issues.

They're made from 3/8" thick steel and are a lot stronger than the round ones, here are some pics of a typical one...

(click photo to enlarge)

This drawing is for the Jet 1221 which fits quite a few of the small lathes.

If this size doesn't work for your lathe give me the two measurements listed below and I'll custom make one for you.

Measurements needed are...

1- Distance between ways.

2- Diameter of bolt that goes through the center.

The price is only $15-plus shipping... WHAT A DEAL!!!

__________________________________________________________________

Custom threaded mandrels for fountain pens...ONLY $20 each

You'll need to send me the die you use and a drilled and tapped blank for each size, both will be returned unharmed.

Pen taps are varied and expensive so I can't afford to have them all, I need the drilled and tapped blank so I can custom fit the mandrel.

If you order a complete 3 piece set (Cap, Body and Section) the price will be $50, that's a $10 discount!

All my mandrels are made to fit a 5/8" (16mm) collet, if you want a different size let me know.

(click photo to enlarge)

Here are some sample drawings of a typical set of mandrels...

____________________________________________________________________________________________________________________________________

1 1/2" die holder adapter that fits in the LMS 1" die holder...$20 each

The die holder adapter in these photos is made from steel, the one you'll get will be aluminum.

I can also make a custom sized holder for any size die you have.

This product is the 1 1/2" adapter ONLY, you will need the Little Machine Shop die holder in order to use my adapter. Here's the link...

https://littlemachineshop.com/products/product_view.php?ProductID=2314&category=

(click photo to enlarge)

_________________________________________________________________________________________________________________________

OFFSET SANDING JIG

This tool, along with three other tools that you most likely already have, allows you to turn your lathe into a 5" disc sander.

We've all sanded on our lathe like this.....

(click photo to enlarge)

The problem with this method is you only use the center of the paper and it still really doesn't work that well.

This tool allows you to OFFSET the blank, which allows you to use the WHOLE disc.

It has 3 different positions that allow you to move to a new spot whenever you want. The V-groove holds a transfer punch and the handle tightens everything down. To use it you just hold even downward pressure on the blank and push it into the disc...REAL simple!

If you don't want to use transfer punches you can put a regular pen mandrel in it and use your tube sleeves to take up the slack.

You can even use my Sanding Mill if you already have one of those.

You'll get the jig and a 1/2" steel bar that fits in your tail stock drill chuck. The steel bar has a flat spot milled in it which allows you to tighten the set screw securely.

WARNING: Do not over tighten the thumbscrew, the plastic cap is pressed on and could come loose.

(click photo to enlarge)

The other three things you'll need are a disc, a set of transfer punches and a 1/2" drill chuck. If you purchased your lathe new it most likely came with a FACE PLATE which you can turn into the sanding disc, if not you can buy them just about anywhere for very little.

If you want a more precise method of holding the blank than transfer punches, how about using my PIN CHUCKS. They're an EXACT fit for your tube and can also be used for CLOSED END turning.

Two uses for the price of one!!

I DON'T SELL THESE THREE THINGS....YOU NEED TO PURCHASE THEM ELSEWHERE!

(click photo to enlarge)

I made my disc out of shelving material that has Formica on it, the Formica works well with the "sticky" discs. I don't recommend the hook and loop discs, they're too soft.

The price for this jig is only $40

THANKS FOR LOOKING!

WAIT...LOOK AT THIS!

One of our fellow members, Mack Cameron (Mack C.) emailed me and asked if I could make an adapter that would fit the morse taper driver of a standard pen mandrel. It sounded like a good idea so I made one to see if it would work...AND IT DOES!

This is what I came up with...

(click photo to enlarge)

What this does is eliminate the need for a drill chuck, so if you don't have a drill chuck then this might be just the ticket!

It has 1/4"-28 threads on it and the other end fits in the jig like the regular 1/2" rod does.

Your order WILL NOT include the MT DRIVER, just the adapter that screws into it.

Here's a link to the MT DRIVER from EXOTIC BLANKS... https://www.exoticblanks.com/morse-taper-driver-arbor-choose-size.html

NOTE: Be sure your morse taper part has 1/4"x28tpi threads, some are METRIC!

If you want this adapter add $5 to the price of the jig.

_______________________________________________________________________________________________________

OFFSET MOUNT

This little device "offsets" the sanding jig by 1/2" and allows you to use a 6" sanding disk. It also uses the "in between" spaces the straight mount doesn't get.

In this photo the RED circles are made with the new "Offset Mount" and the BLUE circles are made with the standard straight mount.

The photo shows a 5" sanding disc mounted on a 6" faceplate...

Here are more pics of the new mount...

The price is $10 each.

Thanks for looking!

TOOL RESTS

These are made from W-1 precision ground tool steel, the shiny stuff, so your turning tools will just glide over the surface.

They are VERY high quality, anybody that's familiar with my products knows that. They all come with a money back guarantee. If FOR ANY REASON you're not happy with it, send it back and I'll return your money, plus shipping, NO QUESTIONS ASKED.

They all come with a brass trim ring and have flats ground in them so you can tighten it with a wrench. This makes for a "modular" system, if you wish you can buy several different length rests and interchange them on the same post.

These tool posts are made of W-1 tool steel which is rust "resistant" NOT rust "proof". If your shop is a high humidity environment then a light coat of wax will help prevent rust.

Post prices are.......

5/8" and smaller...$25

Larger than 5/8"...$35

I stock up to 1" material so we need to talk if you want a post larger than 1".

NOTICE: If you order a 1" post... PLEASE CHECK THE DIAMETER WITH CALIPERS! Some posts are 25mm which is REAL close, but a 1" post won't fit a 25mm banjo.

Rests, UP TO 12", will be $10ea. ADD $1 PER INCH to any rest over 12".

PLEASE NOTE: 9" is the longest length I recommend for a 5/8" post, 12" for a 25mm or 1" post. Having said that I WILL make you any length you want.

As you can see from the prices, this is not some get rich scheme. I'm doing this as a service to my fellow IAP members and frankly, it will give me something to do!!

I encourage you, before you order, to go out to your lathe and be sure of the length you want. I personally like 3.25" for turning one blank at a time between centers, I also sell quite a few 4". That's the beauty of this, it's not a "one size fits all" deal.

Besides the lengths of the rests you want, I'll need two measurements from you... the TOTAL height (post plus rest, just measure your factory rest from TOP to BOTTOM), and the diameter of the post.

Here's a sample of the "height" measurement I need...

(click photo to enlarge)

This one is 6 1/4", yours will probably be different

I take PayPal and personal checks. PM me and I'll send you my PayPal address.

THANK YOU!!!

________________________________________________________________________________________________________________________________________________

FLAT TOP TOOL RESTS

I had a customer request one of these to use with his carbide turning tool and he liked it so much I decided to add it to my inventory.

I don't have a carbide tool...YET!...but I'm told the flat top rest works well with the flat bottom of the tool, giving you more control.

I designed them to fit my standard tool posts so if you have one of mine then these will fit, the only difference is the diameter.

Since the threaded hole in my standard round tool rest is only .125" from the surface I made these "flat" ones .125" bigger. If you have a 5/8" round post then you need to order a 3/4" "flat top" rest, if you have a 1" or 25mm post you'll need to order a 7/8" "flat top" rest.

Since I remove .125" of material to form the flat, THE HEIGHT WILL REMAIN THE SAME, it will just be a tad wider which isn't a problem.

The price for the 3/4" flat top rest is $20.

The price for the 7/8" flat top rest is $25.

PM me and I'll give you my PayPal address.

THANK YOU

_____________________________________________________________________________________________________________________________________________

TOOL POST STOP COLLARS

These STOP COLLARS are designed to keep your tool post at the same height EVERY TIME you use it, no more fumbling around to get it set at the right height, with these you just set it and forget it!

(click photo to enlarge)

They're made from aluminum and have 3 BRASS TIPPED set screws, the brass won't ding up your post like a standard steel one will.

They hold tight and use a 3/32" Allen wrench to tighten.

I can make them ANY size you want but I'm going to stock 5/8"and 1", those are by far the most common.

PLEASE check the diameter of your post with calipers before ordering.

Price is $10 ea.

The price is the same no matter what size you order.

_______________________________________________________________________________________________________

SHOPSMITH TOOL POSTS

Now all of you ShopSmith owners can use any of my custom rests when you

purchase one of these slick new posts...

This shows it with one of my Flat Top rests attached...NOT INCLUDED.

(click photo to enlarge)

Here it is by itself...

You'll get the post and the brass trim ring for only $35, that's a STEAL considering how much machining is involved!:biggrin:

PM me with your order and I'll give you my PayPal address.

THANK YOU

___________________________________________________________________________________________________________________________________

Dial Indicator Posts

and Adapters

In my opinion, everyone who owns a lathe needs a dial indicator. They're invaluable for making sure WHATEVER you have chucked in your lathe is running true. Probably the most common use for penturners is to check the run out on a pen mandrel...

(click photo to enlarge)

Another one I use a lot is checking the run out on a pin chuck...

WHATEVER you turn will benefit from making sure that it's "running true".

With that in mind I designed an economical way to attach a dial indicator to one of my "Custom Tool Rests"...

This shows the two most common sizes, the one on the left has 1/2" threads and fits a 1" post, the one on the right has 3/8" threads and fits on a 5/8" post.

Here it is with the DI installed but before it gets screwed onto the post...

Here it is screwed onto my 1" post...

All I need from you is the thread size of your post. The cap screw is INCLUDED and takes a 3/16" allen wrench.

As with all my custom made tools, these are economically priced to be affordable to everyone... $10 ea.

For those of you that don't have one of my tool rests or for those that would like a DEDICATED DI holder( which I highly recommend) I designed this...

I can make them any size, just measure the diameter of you factory rest. I'll also need the distance from the TOP of your banjo to the CENTER LINE of your lathe.

Here's a photo of the measurement I need, 4" on my lathe.

(click photo to enlarge)

As you can see in the photo, these are made from aluminum and have a "stop" on them. That stop enables you to SET IT AND FORGET IT! Every time you grab it it will be set to the correct height, that's a real nice feature. I need that banjo/center line dimension to make sure the stop is in the right position. It has about 1/2" of adjustment in it so when you get it you just set it once and...FORGET IT!

The stop is milled to the radius of the post to make it more functional and to give it a cleaner look.

All the screws are included, you'll need a 3/16" allen wrench for the DI and a 9/64" for the stop.

The dial indicator is NOT provided, that's something you will have to buy yourself.

I recommend a standard AGD GROUP 2 DI with a 2 1/4" dial and 1" of travel.

BE SURE TO ORDER THE INDICATOR WITH A LUG BACK, you need the lug to be able to bolt it to the holder.

Here's one at Amazon ...1" Dial Indicator

The price for my DEDICATED DI POST is only $20!

____________________________________________________________________________________________________________________________________________________

PIN CHUCKS

See my video on how get rid of the runout on your Pin Chuck... Pin Chuck Video

These pin chucks are custom made for any size pen you want to make, most folks use them to make "closed end" pens but they can be used for ANYTHING with a hole in it that you want to turn on a lathe.

They're made from the same tool steel as my TOOL RESTS and will last forever....IF you take reasonable care of them!

They are approx. 4" long and have a 1/8" pin that fits in an 5/8" long slot. The turned down part that fits inside the tube is about 1/2" longer than the tube so you have some room to work on the end of your blank.

The little "dimple" you see is a reference mark so when you're done and want to remove the blank, you turn the chuck so the dimple is on top, that way the pin won't fall on the floor and roll under something........can you say ..." Murphy's Law"?

All my standard PIN CHUCKS are made from 1/2" material and will fit either a 1/2" or 13mm collet. My 7mm PIN CHUCKS fit a 1/4" or 7mm collet. If you need a PIN CHUCK larger than 1/2" I'll let you know what size collet you'll need.

I have a lot of different pen kits in stock but I don't have them all. If you want a pin chuck to fit something I don't have I'll either order that size tube OR you can send me the tubes and I'll return them with your order. Measuring the I.D. of tubes with calipers is fine for some applications but not for this, I like to have the tubes I'm fitting on hand so I can insure a perfect fit.

This is the pin chuck mounted in a collet chuck, ready to accept a blank.

This shows a sample that I turned down to a pen cap shape....works like a charm!

Pin chucks are "tube specific" so you'll need TWO pin chucks to do both halves of a pen.

These little guys are only$17 ea. , no matter what size you want!

PM me and I'll give you my PayPal address.

_________________________________________________________________________________________________________

SANDING MILL 2.0

This is my new version of an old tool....

(click photo to enlarge)

I had some requests for a sanding mill that had TWO flat and true sides so folks could use the short side for smaller stuff.

I also wanted a simpler way to make them.......

The old way with wood, brass and glue took WAY too long to make, consequently I had to charge what I thought was a little too much. With this new design not only will you be getting a better product, you'll be paying LESS for it, how often does that happen?!

THIS TOOL DOES THE SAME JOB AS THE OLDER MODEL SO IF YOU ALREADY HAVE THE OLDER VERSION YOU DON'T NEED THIS ONE.

(Unless of course you really want one!:biggrin

This new version does NOT include sandpaper or punch!

To make the discs get some sticky backed sandpaper and cut it into small squares, I use the 5" round discs made for an orbital sander. A regular notebook paper punch will punch a perfectly sized hole for the shaft.

I use 100 grit for mine but experiment and see what's right FOR YOU!

Here's a photo of the sanding mill....

The price for the new model is ONLY $20!

This part shows my old style mill but the process is the same with the new one....

Here's a photo with one of my sleeves installed. The rod on the mill is the same size as your standard "A" penturners mandrel so you can make sleeves from a slimline tube if you like.

The one in the photo is made out of Delrin to fit a Sierra style pen tube...

Here it is with the Sierra barrel attached and ready to go...

I use mine at about 1,000 rpm and just push real lightly, it's really easy to use and you'll get the hang of it right away!

If you don't want to make your own sleeves I charge $5 each for sleeves that are an exact fit for the tube.

PLEASE note that this is a FINISHING tool, it's meant to be used on already turned barrels and really excels at removing CA and squaring things up prior to assembly. You'll be amazed at how much better everything fits after using this tool.

See my OFFSET LATHE SANDING JIG if you need a more aggressive tool.

--------------------------------------------------------------------------------------------------------------------------

17pc. SET of TUBE SLEEVES

These sleeves are NOT an exact fit like the ones I offer above, these are the same sizes as a set of transfer punches. These are made from wood, I try and get them to the exact size marked on them but that's next to impossible. The exact number isn't important, the idea is to pick the largest one that will fit inside your tube.

These are used the same way the transfer punches are used for my OFFSET SANDING JIG, you need to use a slight downward pressure when using them. While they are not an exact fit there is approx. .015" between sleeves so the one you choose will be REAL close. Tolerance on sleeves...+/- .005"

The price for 17 sleeves AND this nifty little stand made from MDF is only $50. That's a $35 savings on the sleeves and the stand is FREE!

BUT WAIT..........CHECK OUT THIS DEAL!!!!!!

For only $60 I'll include one of my SANDING MILLS!!

That means you get the SANDING MILL for ONLY $10, WHAT A DEAL!!!!

Thanks for looking!

---------------------------------------------------------------

Straight Shank Dead Centers

I made one of these for Mike (navycop) who has a Shopsmith and he wanted to turn between centers with custom bushings. The Shopsmith doesn't have a Morse taper so he needed a center with NO taper that he could mount in his drill chuck.

Afterwards I got to thinking...I'll bet these would work great for those of us with Beall or other brands of collet chucks who are tired of removing the chuck so we can insert our Morse taper dead center into our headstock and turn between centers.

The one in the photo is 1/2" X 3" but I can make them ANY diameter and ANY length you want. They are STRAIGHT, i.e. NO TAPER, and have a standard 60 degree end. They're made from the same high quality tool steel as my Custom Tool Rests.

I harden them by heating the tip to a cherry red and quickly plunging it into cold water, I tried to turn one on my metal lathe AFTER it was hardened and I dulled my HSS cutter so I know it's hard enough for TBC.

I'm asking $12 each...ANY DIAMETER, ANY LENGTH UP TO 6", $1 per inch after that.

PM me and we'll discuss your needs and I'll give you my PayPal address for payment.

THANK YOU!

Lathe Sanding Table

NOTICE : This table is NOT for squaring blanks to the tube, see my OFFSET LATHE SANDING JIG for that.

This is the answer for all of you who would like a disc sander but don't have the room or the budget for a stand alone model. I designed it to screw on to my tool posts so if you already have one you're all set, if not then you will need to order a post to make it work.

It's made from 1/2" MDF for flatness and stability and is covered with authentic Formica for a smooth surface and a lifetime of use. It also has a 1/4" x 1/4" channel routed on two sides so you can make your own fences.

The mounting block is made from 5/8" thick solid aluminum.

If you need a post I'll discount it $5 if you buy the post and table together.

The price for the table only is $25-plus shipping.

Table plus 5/8" post...$45-plus shipping

Table plus 1" post...$55- plus shipping.

You need to make your own fences, I won't be offering them for sale. I just used scrap wood and CA glued it together.

Attachments

-

DIAL 008.jpg93.9 KB · Views: 14

DIAL 008.jpg93.9 KB · Views: 14 -

Pin Chuck 006.jpg61.8 KB · Views: 16

Pin Chuck 006.jpg61.8 KB · Views: 16 -

DIAL 018.jpg84.9 KB · Views: 11

DIAL 018.jpg84.9 KB · Views: 11 -

DIAL 011.jpg95.5 KB · Views: 12

DIAL 011.jpg95.5 KB · Views: 12 -

DIAL 006.jpg100.2 KB · Views: 13

DIAL 006.jpg100.2 KB · Views: 13 -

DIAL 014.jpg95.1 KB · Views: 14

DIAL 014.jpg95.1 KB · Views: 14 -

DIAL 001.jpg64.1 KB · Views: 11

DIAL 001.jpg64.1 KB · Views: 11 -

Pin Chuck iap ad.jpg43.5 KB · Views: 14

Pin Chuck iap ad.jpg43.5 KB · Views: 14 -

sanding mill operation 004.jpg63.1 KB · Views: 10

sanding mill operation 004.jpg63.1 KB · Views: 10 -

sanding mill operation 003.jpg61.8 KB · Views: 11

sanding mill operation 003.jpg61.8 KB · Views: 11 -

1558271146177.png23.8 KB · Views: 9

1558271146177.png23.8 KB · Views: 9 -

Pen mandrel DI run out.jpg2.7 KB · Views: 10

Pen mandrel DI run out.jpg2.7 KB · Views: 10 -

Pin chuck DI run out.jpg2.7 KB · Views: 13

Pin chuck DI run out.jpg2.7 KB · Views: 13 -

DI adapters.jpg1.5 KB · Views: 14

DI adapters.jpg1.5 KB · Views: 14 -

Ded DI post measure.png17.5 KB · Views: 9

Ded DI post measure.png17.5 KB · Views: 9 -

Sand Mill 2.0.JPG163.3 KB · Views: 11

Sand Mill 2.0.JPG163.3 KB · Views: 11 -

DB81AC6F-79C5-44B4-A247-30648F9F3236.jpeg55.7 KB · Views: 12

DB81AC6F-79C5-44B4-A247-30648F9F3236.jpeg55.7 KB · Views: 12 -

1645881575804.png51.1 KB · Views: 14

1645881575804.png51.1 KB · Views: 14 -

Bock New drawing.jpeg85.1 KB · Views: 12

Bock New drawing.jpeg85.1 KB · Views: 12 -

IMG_9230.JPG132.7 KB · Views: 14

IMG_9230.JPG132.7 KB · Views: 14 -

IMG_9231.JPG86.7 KB · Views: 9

IMG_9231.JPG86.7 KB · Views: 9 -

IMG_9229.JPG149.1 KB · Views: 12

IMG_9229.JPG149.1 KB · Views: 12 -

IMG_9228.JPG155.3 KB · Views: 12

IMG_9228.JPG155.3 KB · Views: 12 -

IMG_9235.JPG74.5 KB · Views: 15

IMG_9235.JPG74.5 KB · Views: 15 -

Scan2023-06-15_095234.jpg80.2 KB · Views: 11

Scan2023-06-15_095234.jpg80.2 KB · Views: 11 -

Scan2023-06-15_095945.jpg83 KB · Views: 12

Scan2023-06-15_095945.jpg83 KB · Views: 12 -

Tailstock Clamp.jpg95.1 KB · Views: 11

Tailstock Clamp.jpg95.1 KB · Views: 11