Rangertrek

Member

Delta Midi-Lathe Review

Model 46-460

This is the second lathe I have owned. I bought my first lathe in August 2008 and this was my first experience with wood turning. My first lathe was a PSI Turncrafter Pro Variable Speed and is the basis for any comments about comparisons with the Delta. I recently purchased this lathe because I wanted a lathe with a little more power and capacity as I have a growing interest in turning bowls. My wood turning experience consists of over 400 pens, six bowls, a few pendants, tree ornaments, and a few bottle stoppers, etc. So my evaluation and comments are based on this experience.

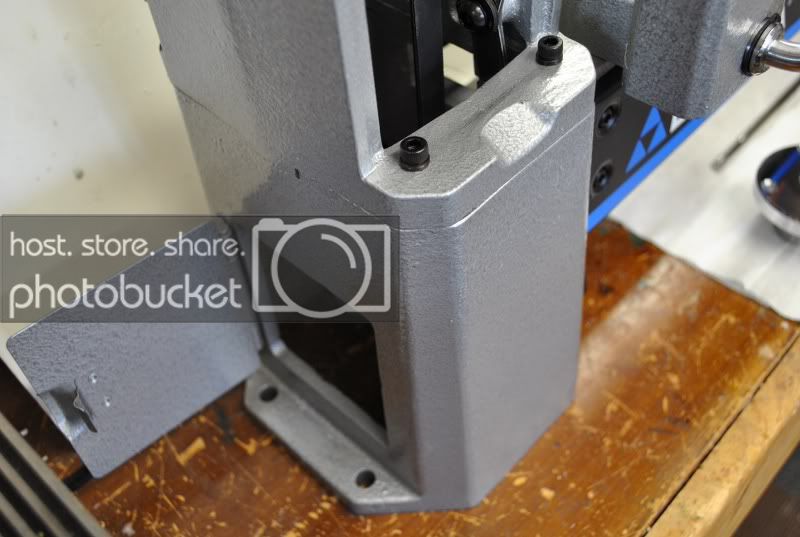

I have no connection to Delta (other than owning a few of their tools) and have no interest or received any compensation in connection with this review. I bought the lathe at a retail store and paid list price ($599) less a small discount coupon. I did not buy the adjustable lathe stand, as mine will go on my workbench. I did get a brief demonstration of this lathe and thoroughly examined the floor model. I had also read several lathe reviews prior to deciding on this make and model. So much for the disclaimer, now on with the review.

Manufacturer's Description

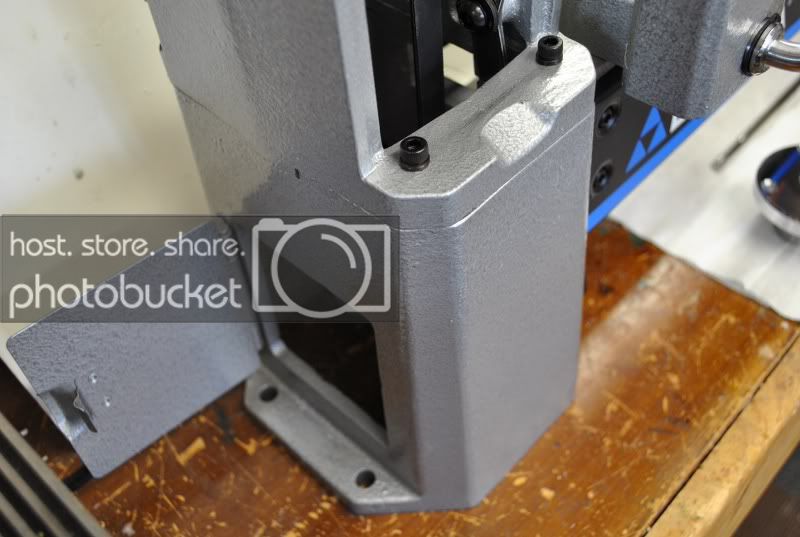

Delta Midi-lathe Model 46-460. Electronic variable speed with a 1 HP max. motor, speed 250 – 4,000 rpm. Turn objects up to 12-1/2" diameter over the bed and 9" diameter over the tool rest bed. The maximum distance between centers is 16-1/2". It uses a #2 Morse Taper and 1x8 spindle.

It comes with a five (5) year warranty. The owner manual has 18 pages of information and I found it to be well written and without errors. An extension bed is available.

The box contained – the lathe with the tailstock mounted, a faceplate, tool rest base (mounted) 10" tool rest, 6" tool rest, hex wrench, live center, spur center, knockout bar (with rubber grip), and faceplate wrench. Out of the box, the assembly is basically done for you as tailstock and tool rest base are mounted. The only assembly listed in the manual is to bolt down to a table or stand. The unit and parts were in excellent condition, no scratches, and no marks. I did clean manufacturing grease from the ways and applied a few coats of wax.

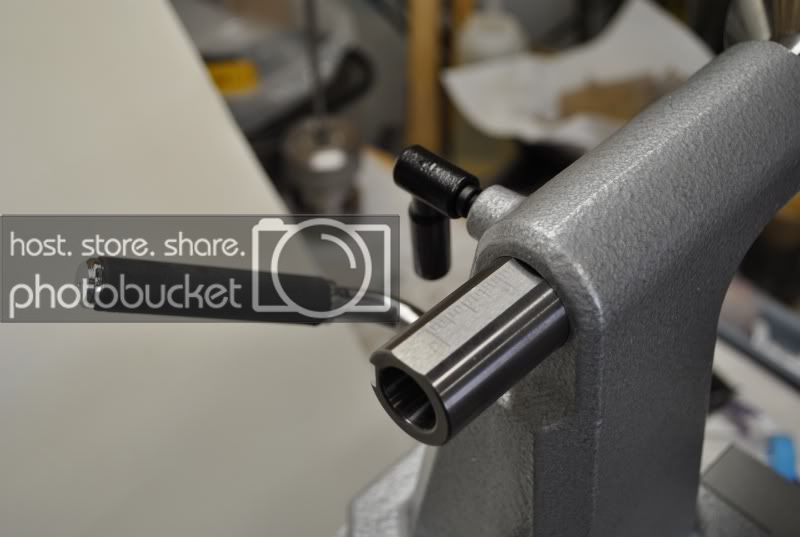

The handles for the tool rest base and tailstock are polished metal and have rubber grips. They feel very sturdy and lock down easily and feel secure. The tool rest and the quill have metal locking handles that work easily and are spring loaded for ratcheting out of the way. [My prior lathe had plastic handles and I managed to break a couple of those.] The tailstock crank wheel has a 'stop pin' that will eject a live center or chuck when retracted so you don't need to use the knockout bar.

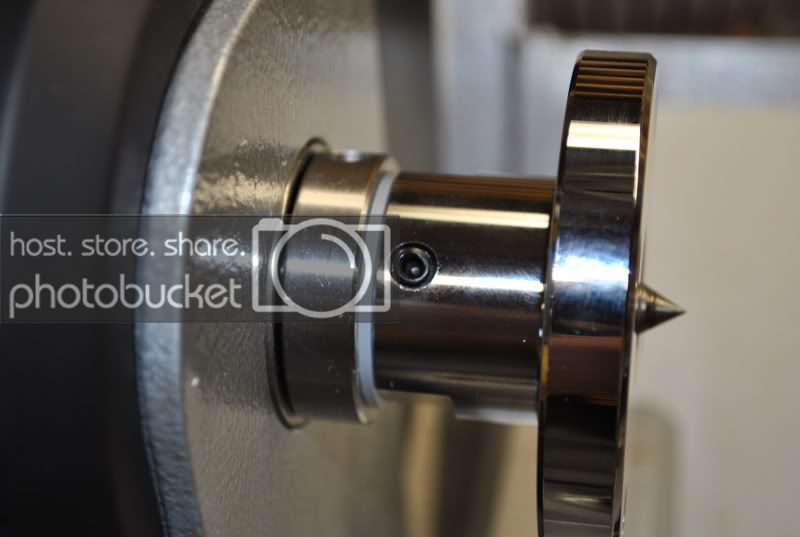

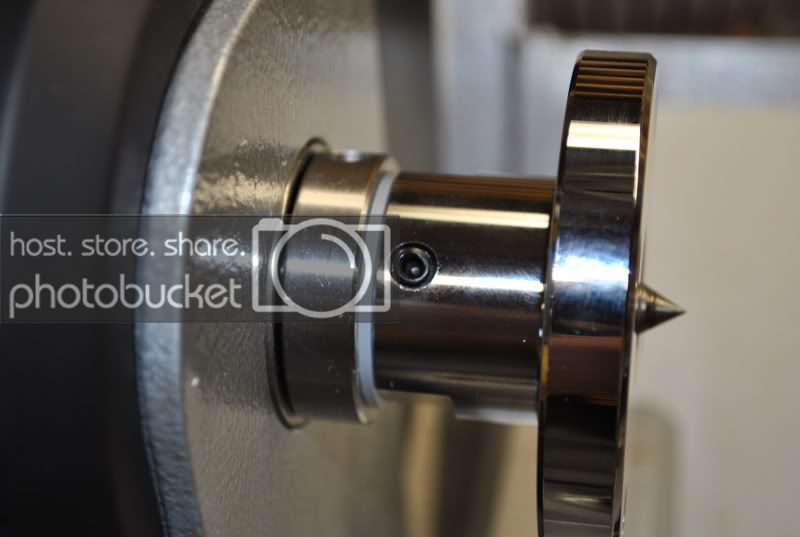

The faceplate is polished metal and has two hex locking screws for mounting. It is 4" diameter with four screw mounting holes. The ways are not as highly polished and not as smooth as my PSI model. The banjo does not slide quite as easily. I put a dead center in the headstock and a live center in the tailstock and pushed them together and saw a perfect dead-on alignment, no adjustments needed.

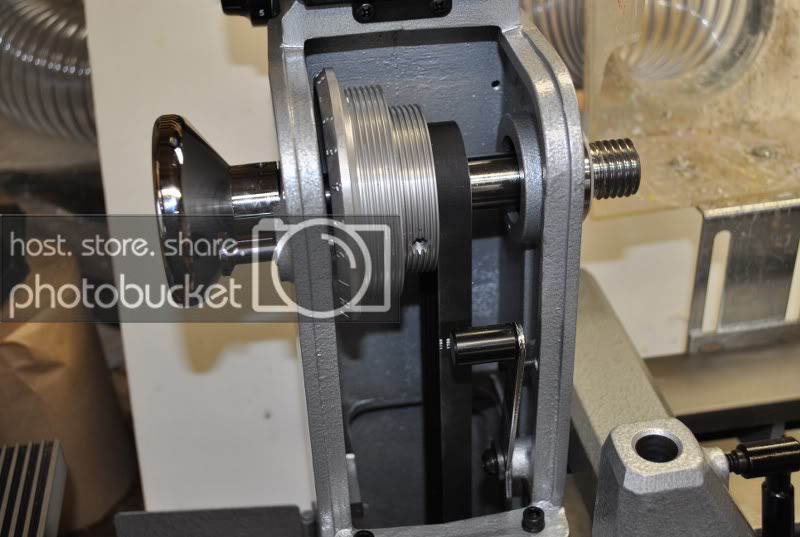

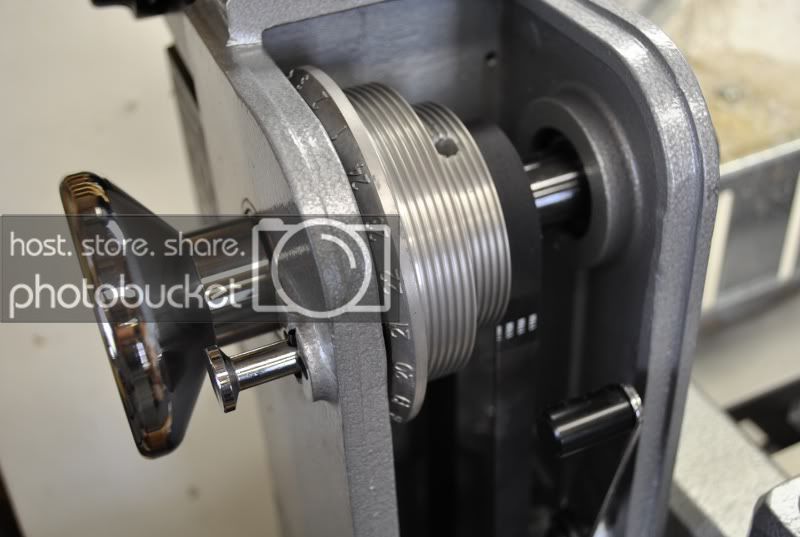

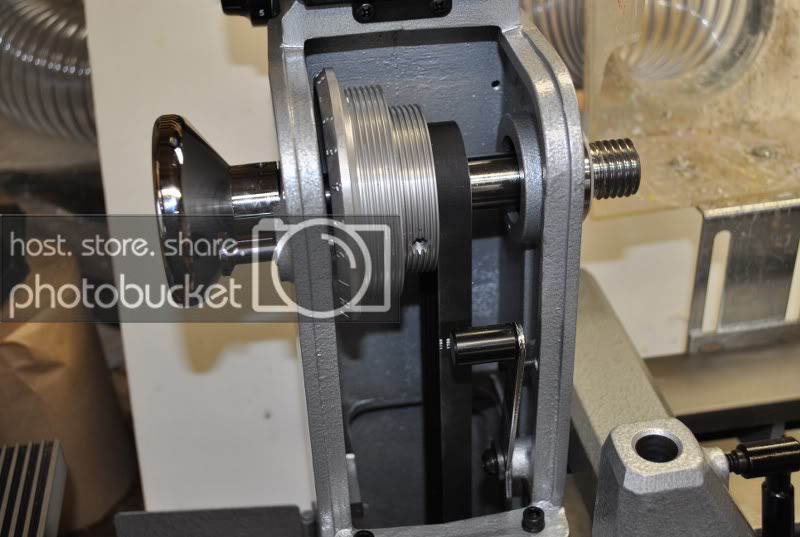

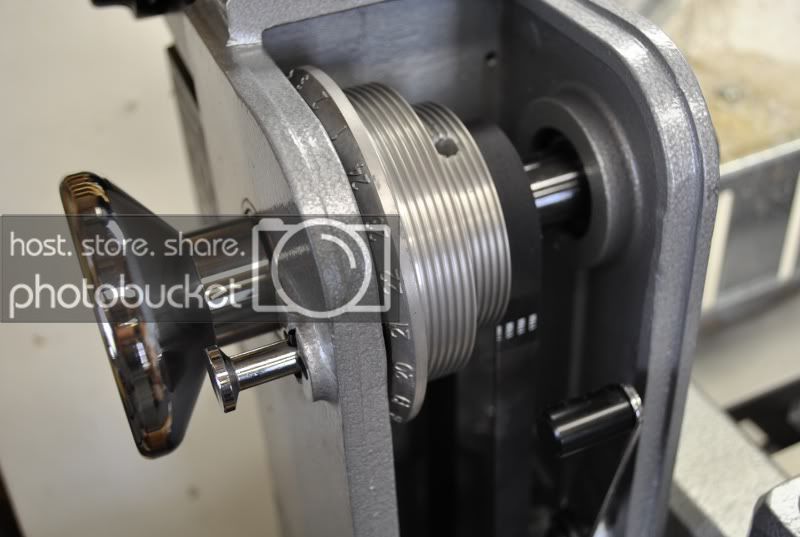

The variable speed pulleys (three sets) and belt are accessed from a large plastic door on the front of the tailstock. There is a smaller door on the lower left side. Both are very easy to use and the belt is easily moved to other positions. There is a single tension lever to tighten the belt which works easily. The belt is ½" wide and has ridges to match the pulley wheels (no slipping). There is a factory set thumb wheel to change the tension on the tension lever. Belt changing is much easier and faster than my prior lathe. The lathe has a 24 position indexing wheel that is well marked.

The speeds are listed as follows for the three sets of wheels: 250 – 750 rpm, 600 -1,800 rpm, 1,350 – 4,000 rpm. The speed control is on the top left of the tailstock and the large red on/off switch is located on the top back. There are speed reference labels on both the left side of the tailstock and under the lid of the pulley cover door. The on/off switch can be locked (padlock). This lathe also has reverse capability and this switch is just in front of the on/off switch. The motor does have an overload protection. If overloaded, turn off and allow to cool for 3-5 minutes.

The first thing I noticed about this lathe was how quite it runs. My wife also commented on how quiet it ran. I happen to have access to a sound level meter and check both the Delta and the PSI. I did the testing at the low and high range of the high speed set of pulleys. The sound levels were: Delta 48-59 db. The PSI was at 66 – 76 db. db = decibels.

The Bottom Line

The 46-460 met all my expectations. I especially noticed that it was smoother running and much less quiet than my prior lathe. I have not bolted it down to my bench and doubt that I will need to. I have noticed no vibration or movement while in operation. I have not yet mounted anything over 8" diameter.

Is this a good value? In my opinion, it is. There are other less expensive units in the midi-lathe range. I think the quality of construction and workmanship score high points for this unit. Did I mention how quiet is runs? For my $600 I am very satisfied with the lathe so far. I look forward to taking it through the warranty period. Thanks for any comments, questions, or feedback.

Thanks for any comments, questions, or feedback.

Model 46-460

This is the second lathe I have owned. I bought my first lathe in August 2008 and this was my first experience with wood turning. My first lathe was a PSI Turncrafter Pro Variable Speed and is the basis for any comments about comparisons with the Delta. I recently purchased this lathe because I wanted a lathe with a little more power and capacity as I have a growing interest in turning bowls. My wood turning experience consists of over 400 pens, six bowls, a few pendants, tree ornaments, and a few bottle stoppers, etc. So my evaluation and comments are based on this experience.

I have no connection to Delta (other than owning a few of their tools) and have no interest or received any compensation in connection with this review. I bought the lathe at a retail store and paid list price ($599) less a small discount coupon. I did not buy the adjustable lathe stand, as mine will go on my workbench. I did get a brief demonstration of this lathe and thoroughly examined the floor model. I had also read several lathe reviews prior to deciding on this make and model. So much for the disclaimer, now on with the review.

Manufacturer's Description

Delta Midi-lathe Model 46-460. Electronic variable speed with a 1 HP max. motor, speed 250 – 4,000 rpm. Turn objects up to 12-1/2" diameter over the bed and 9" diameter over the tool rest bed. The maximum distance between centers is 16-1/2". It uses a #2 Morse Taper and 1x8 spindle.

It comes with a five (5) year warranty. The owner manual has 18 pages of information and I found it to be well written and without errors. An extension bed is available.

The box contained – the lathe with the tailstock mounted, a faceplate, tool rest base (mounted) 10" tool rest, 6" tool rest, hex wrench, live center, spur center, knockout bar (with rubber grip), and faceplate wrench. Out of the box, the assembly is basically done for you as tailstock and tool rest base are mounted. The only assembly listed in the manual is to bolt down to a table or stand. The unit and parts were in excellent condition, no scratches, and no marks. I did clean manufacturing grease from the ways and applied a few coats of wax.

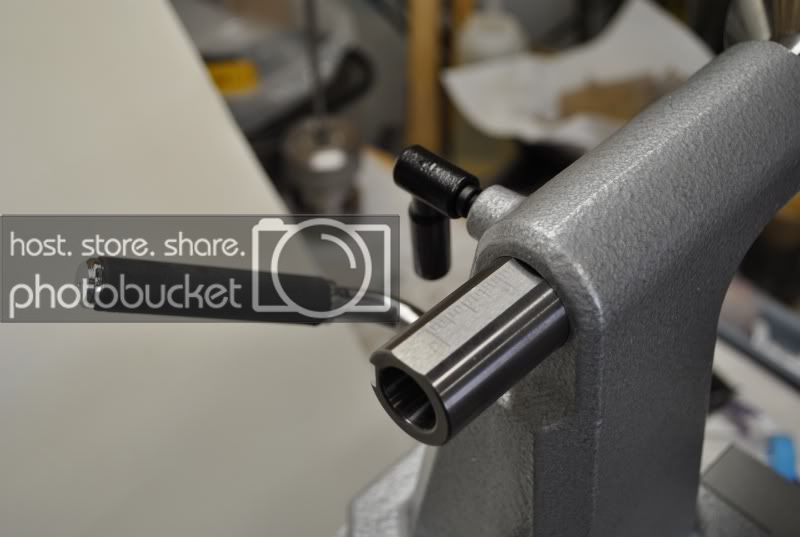

The handles for the tool rest base and tailstock are polished metal and have rubber grips. They feel very sturdy and lock down easily and feel secure. The tool rest and the quill have metal locking handles that work easily and are spring loaded for ratcheting out of the way. [My prior lathe had plastic handles and I managed to break a couple of those.] The tailstock crank wheel has a 'stop pin' that will eject a live center or chuck when retracted so you don't need to use the knockout bar.

The faceplate is polished metal and has two hex locking screws for mounting. It is 4" diameter with four screw mounting holes. The ways are not as highly polished and not as smooth as my PSI model. The banjo does not slide quite as easily. I put a dead center in the headstock and a live center in the tailstock and pushed them together and saw a perfect dead-on alignment, no adjustments needed.

The variable speed pulleys (three sets) and belt are accessed from a large plastic door on the front of the tailstock. There is a smaller door on the lower left side. Both are very easy to use and the belt is easily moved to other positions. There is a single tension lever to tighten the belt which works easily. The belt is ½" wide and has ridges to match the pulley wheels (no slipping). There is a factory set thumb wheel to change the tension on the tension lever. Belt changing is much easier and faster than my prior lathe. The lathe has a 24 position indexing wheel that is well marked.

The speeds are listed as follows for the three sets of wheels: 250 – 750 rpm, 600 -1,800 rpm, 1,350 – 4,000 rpm. The speed control is on the top left of the tailstock and the large red on/off switch is located on the top back. There are speed reference labels on both the left side of the tailstock and under the lid of the pulley cover door. The on/off switch can be locked (padlock). This lathe also has reverse capability and this switch is just in front of the on/off switch. The motor does have an overload protection. If overloaded, turn off and allow to cool for 3-5 minutes.

The first thing I noticed about this lathe was how quite it runs. My wife also commented on how quiet it ran. I happen to have access to a sound level meter and check both the Delta and the PSI. I did the testing at the low and high range of the high speed set of pulleys. The sound levels were: Delta 48-59 db. The PSI was at 66 – 76 db. db = decibels.

The Bottom Line

The 46-460 met all my expectations. I especially noticed that it was smoother running and much less quiet than my prior lathe. I have not bolted it down to my bench and doubt that I will need to. I have noticed no vibration or movement while in operation. I have not yet mounted anything over 8" diameter.

Is this a good value? In my opinion, it is. There are other less expensive units in the midi-lathe range. I think the quality of construction and workmanship score high points for this unit. Did I mention how quiet is runs? For my $600 I am very satisfied with the lathe so far. I look forward to taking it through the warranty period.

Last edited: