MesquiteMan

Retired Head Moderator

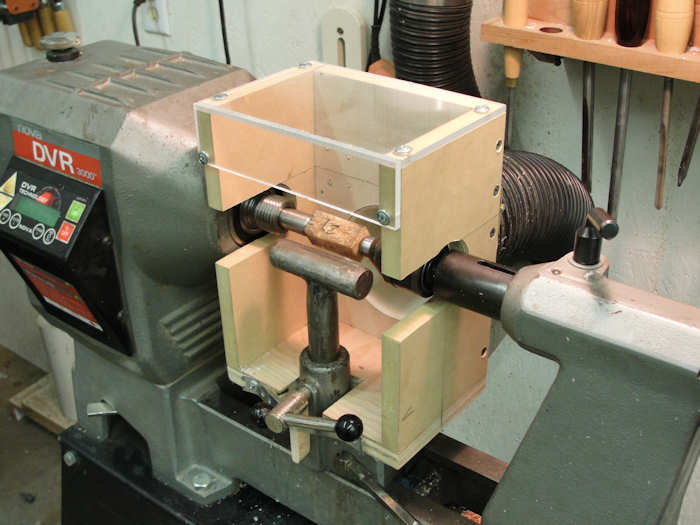

I have been seeking the ever elusive "darn near 100%" dust and CHIP collection while penturning on the lathe. I have got the dust collection part down but even with an 1,800 cfm cyclone system with 6" duct work and a 4", very short drop to the lathe with a large dust hood, I still was not getting really good CHIP collection. Well, that is now a problem of the past! I am getting 99.997% COMPLETE dust AND chip collection with this gizmo that I came up with...

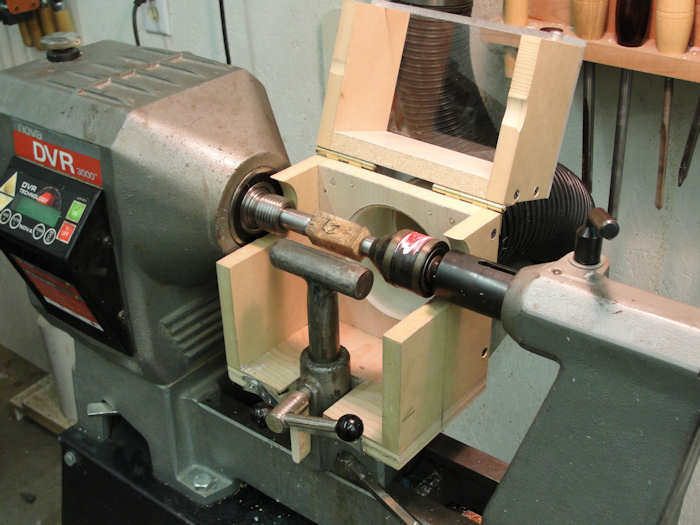

Once I came up with this design, I realized I had a new problem...what do I do when I sand and apply my CA finish. I could just see the nice clear plexi get all spotted with little dots of flung off CA and there was just not enough room in there to do any real sanding. What to do?....hinges of course!

This works INCREDIBLY well! See the 3 or 4 chips at the bottom of the last pic on the black base for my lathe? That is all I missed after rough turning 15 cactus blanks! The other really nice part...I don't need to wear my face shield while turning now! Of course, I still do when applying CA.

Here is a short youtube video showing it in use and how well it works! In the video, I am rough turning an "Original Cactus Blank"" between centers (I have 34 pens to make) with my bowl gouge (as I always do). The final sizing and shaping will be done later.

http://www.youtube.com/watch?v=1CI5lAYUwKg

Once I came up with this design, I realized I had a new problem...what do I do when I sand and apply my CA finish. I could just see the nice clear plexi get all spotted with little dots of flung off CA and there was just not enough room in there to do any real sanding. What to do?....hinges of course!

This works INCREDIBLY well! See the 3 or 4 chips at the bottom of the last pic on the black base for my lathe? That is all I missed after rough turning 15 cactus blanks! The other really nice part...I don't need to wear my face shield while turning now! Of course, I still do when applying CA.

Here is a short youtube video showing it in use and how well it works! In the video, I am rough turning an "Original Cactus Blank"" between centers (I have 34 pens to make) with my bowl gouge (as I always do). The final sizing and shaping will be done later.

http://www.youtube.com/watch?v=1CI5lAYUwKg

Attachments

Last edited: