Darley

Member

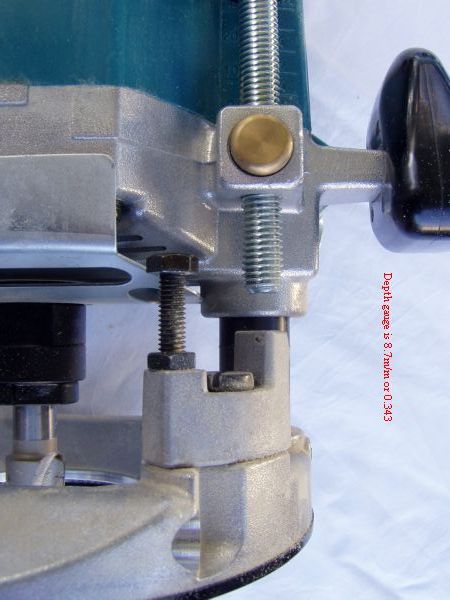

I should post this some time ago and some friends reminder me to do, so every one can profit of this and make good use of it, I don't have a well equipped work shop so I do most by hand, tray are cheap to do I collect most of my off cut wood from a cabinet maker, nice square cut, I use my Makita router fitted with a 19m/m (3/4")bull nose bit

I do plunge cutting and free hand, din't have the time to do a jig, a safe way to is to use a router table if you got one, depth of the cut is 8.7 m/m or .343" you can do a little be deep but I find for me is easy to pick up the pen. An Emperor fit well

The piece of scrap wood I got for this example is a small laminated shelve, I draw the lines at 22m/m ( 7/8" I think) then draw the cutting line at 16m/m like that when the cut is done you will have a space between cuts of 3m/m.

note that the board is screw on to a waste plywood board, now to have a good edge when cutting I add some scrap wood length on the side and the edges will have a neat cut

Sorry if I din't take a shot of the full board when cuts are done, but here's 2 tray for boxes ( note is only 7 slots )

I cut the edge of the box and glue them up attention don't glue the tray yetglue only the edge of the frame for peace of mind I add some tape at the coners of the tray like that it will not stick to the frame

next I remove the tray from the frame and glue the felt with PVA, I brush the glue then apply the felt and give the shape with a wooden dowel

here's the finished frame and glass lid

Here's another tray for display 12 slots ( run short of felt [xx(]

[xx(]

hope this help

I do plunge cutting and free hand, din't have the time to do a jig, a safe way to is to use a router table if you got one, depth of the cut is 8.7 m/m or .343" you can do a little be deep but I find for me is easy to pick up the pen. An Emperor fit well

The piece of scrap wood I got for this example is a small laminated shelve, I draw the lines at 22m/m ( 7/8" I think) then draw the cutting line at 16m/m like that when the cut is done you will have a space between cuts of 3m/m.

note that the board is screw on to a waste plywood board, now to have a good edge when cutting I add some scrap wood length on the side and the edges will have a neat cut

Sorry if I din't take a shot of the full board when cuts are done, but here's 2 tray for boxes ( note is only 7 slots )

I cut the edge of the box and glue them up attention don't glue the tray yetglue only the edge of the frame for peace of mind I add some tape at the coners of the tray like that it will not stick to the frame

next I remove the tray from the frame and glue the felt with PVA, I brush the glue then apply the felt and give the shape with a wooden dowel

here's the finished frame and glass lid

Here's another tray for display 12 slots ( run short of felt

hope this help