gketell

Local Chapter Leader

In another thread I talked about using coat hangers as a depth/thickness gauge for hollow ornaments. One of the readers was having trouble following my description so I thought I would post up some pictures to help him understand and then I thought some others might gain from knowing how to make/use "free" depth gauges.

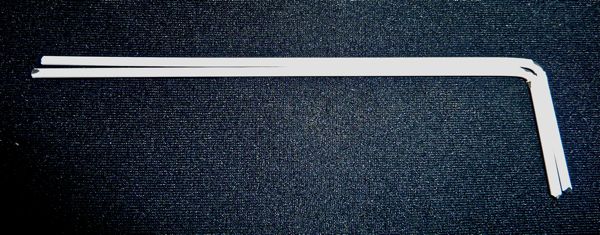

In this first picture you see that I have cut a hanger into two equal length pieces and then grabbed them both with a pair of pliers and bent them both equally.

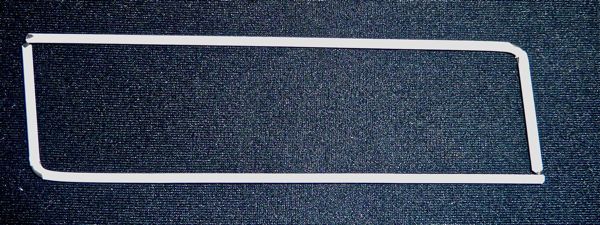

Now when you flip one of them over you get a parallelogram (rectangle if you bent them at 90-degrees).

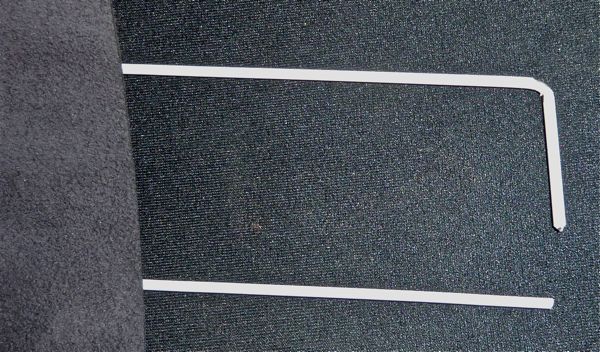

The benefit of this is that if you keep them parallel then when you spread one side out the other side will be spread equally. The next two pictures show me measuring the thickness of a USB thumb drive two different ways:

So now imagine that you are measuring the wall thickness of a turned object where you can't see the thickness and you can't feel it. You stick one end of one "measuring wire" into the ornament and then you line up the other one so it stays parallel and the open gap you CAN see will show you the exact thickness of what you are measuring.

Just be sure to keep the wires parallel and the corners "lined up" and you will be able to see the invisible. And the pieces of wire don't have to be bent at 90 degrees; use whatever angle allows you to get to the area you want to measure. As long as both pieces of wire are exactly the same this will work.

Happy Turning.

GK

In this first picture you see that I have cut a hanger into two equal length pieces and then grabbed them both with a pair of pliers and bent them both equally.

Now when you flip one of them over you get a parallelogram (rectangle if you bent them at 90-degrees).

The benefit of this is that if you keep them parallel then when you spread one side out the other side will be spread equally. The next two pictures show me measuring the thickness of a USB thumb drive two different ways:

So now imagine that you are measuring the wall thickness of a turned object where you can't see the thickness and you can't feel it. You stick one end of one "measuring wire" into the ornament and then you line up the other one so it stays parallel and the open gap you CAN see will show you the exact thickness of what you are measuring.

Just be sure to keep the wires parallel and the corners "lined up" and you will be able to see the invisible. And the pieces of wire don't have to be bent at 90 degrees; use whatever angle allows you to get to the area you want to measure. As long as both pieces of wire are exactly the same this will work.

Happy Turning.

GK