LEAP

Member

Thanks guys, got my design drawn out going to make my first attack on the wax tomorrow.

Is this thing still going? If so I have a question regarding types of wax I could use. I have alot of bees wax and was wondering if that would work? I know that jewelers wax is cheap thanks to Mike but why spend the money if I don't have to?

Absolutely yes.Bruce,

Can I use one of my two for a necklace pendant? Obviously I'd be paying you for the material etc, but I don't have access to my crucible/centerfuge etc at the moment, being out of state. Any way we can make that happen?

It may take a little ingenuity, but I would say yes. Post what you want to make including some dimensions, and lets see if we can come up with a plan.The only chuck I have for my lathe is a drill chuck. Would it still be possible to make the necessary parts to cast for a pen?

Absolutely yes.Bruce,

Can I use one of my two for a necklace pendant? Obviously I'd be paying you for the material etc, but I don't have access to my crucible/centerfuge etc at the moment, being out of state. Any way we can make that happen?

I've made quite a few pens, but for some reason never a click. Perhaps some others who have will chime in with ideas. In any event, if I were to try what you are describing, I would try to prototype the pen with wax parts and see how they look. Be careful not to make them too heavy. Silver weight 10 times what wax does. Keep us posted on your progress. A few pictures might solicit some more ideas.I only started to really think about this last night. I'm thinking click pen if possible using or 8MM tubes or something in that general size perhaps single tube. Nib, something between straight taper and rounded taper not sure about it yet. Clip, a lot like your native american axe handle round or square with a cord wrapped around the bottom. The final or centerband maybe a ring with a cord wrapped up the inside and down the outside maybe slightly flattened so the cord is not quite so round. Clicker would have a matching wrap like the clip that would push down to the final when fully depressed. This would be my daily driver and that is why I would like a thinner pen that is a click pen. I think I could do it but I have never tried something like this before. Does anybody know where to get a reliable click mechanism and how one would go about turning it into a pen?

You may have trouble splitting this, but there's no reason why you couldn't file away one half. Wax is pretty easy to file.Thats awesome Mike, I'm working on a lighthouse clip. I originally cut it from a flat piece of wax but the symmetry is a little off so Im thinking of turning the basic shape round then splitting it length wise to get two pieces to work with. This would be so much easier on a metal lathe than doing freehand.

You may have trouble splitting this, but there's no reason why you couldn't file away one half. Wax is pretty easy to file.Thats awesome Mike, I'm working on a lighthouse clip. I originally cut it from a flat piece of wax but the symmetry is a little off so Im thinking of turning the basic shape round then splitting it length wise to get two pieces to work with. This would be so much easier on a metal lathe than doing freehand.

Its been about 6 weeks since the start of this. In mid January, I plan to send out a batch of wax for casting.

If you are still interested in joining this casting session, please contact me before then by post or pm. If its a matter of a few days one way or another, I can wait so don't rush your project. If you think it will take significantly longer, there may be other options.

If you originally showed interest and are having difficulty and need help, there are several of us available by post or pm.

Its been about 6 weeks since the start of this. In mid January, I plan to send out a batch of wax for casting.

If you are still interested in joining this casting session, please contact me before then by post or pm. If its a matter of a few days one way or another, I can wait so don't rush your project. If you think it will take significantly longer, there may be other options.

If you originally showed interest and are having difficulty and need help, there are several of us available by post or pm.

Well, it looks like I'm not gonna' make it :frown:

Let's just say it's been a learning experience and I'll have to get some more wax before I try again.

-Barry

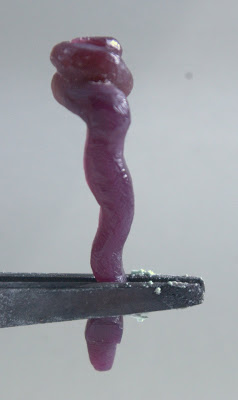

Here's a picture of what I currently use for most of my clips which I tend to hide in the cap. Thickness is about .080".Hey Bruce,

Is there a trick to making the ring for a clip? I'm having a bear of a time with it. the damn things keep breaking. about the only variable I have not tried is bring the wax inside and heating it up to 70 or so as the shop is around 60. I've tried working with 1/4" thick and 1/8", the pieces are just to brittle. The thicker is hard to get the round formed and the thinner too fragile. I'm taking a break from the wax before the frustration factor gets too high. the next thing I'm to try is to turn a piece to the OD then drill the tube size, slice off a piece, then melt a flat piece on to the side for the tab. Thinking back I should have tried this first. Anyway Just needed to vent a bit before going back out to the shop. thanks,