Gary B. Reeter

Member

I am looking to switch to turning between centers but I am finding it hard to find the bushings for the various pen kits I use. Anyone making theses bushing that I can contact? TIA

Gary

Gary

Thanks Dave, but I have visited there sites and they do not have the bushings for a lot of the pen kit I use. I would say the majority of list I use are PSI some Smitty and some Craft Supply. Gary

You can turn TBC with standard bushings. I do it when I don't have the TBC buahings. If you know someone with a metal lathe and a little time they can make them or convert mandrel bushings to TBC. I've had both done.I am looking to switch to turning between centers but I am finding it hard to find the bushings for the various pen kits I use. Anyone making theses bushing that I can contact? TIA

Gary

You can turn between centers and use no bushings. Just use calipers and measure.

I'm with ironman. If you're gonna TBC what's the point of using bushings? They're handy (and almost required) on the mandrel, but if you're gonna TBC you'll need bushings that will fit inside the tube so everything will remain centered. Again, what's the point of that? Get some calipers and eliminate the bushings.

I'm with ironman. If you're gonna TBC what's the point of using bushings? They're handy (and almost required) on the mandrel, but if you're gonna TBC you'll need bushings that will fit inside the tube so everything will remain centered. Again, what's the point of that? Get some calipers and eliminate the bushings.

Because measuring constantly is a pain in the butt.

There are also some good reasons to use bushings I think. One is no risk of expanding the brass tube. 2 is having a nice shoulder against the blank material. 3 is much better drive surface with 60 degree bevels on both the centers as bushings.

But in the end- for me - it's a matter of convenience.

I really dislike tbc without bushings.

For those that don't use them, good for you. Not for me.

Try IAP member NikitasI am looking to switch to turning between centers but I am finding it hard to find the bushings for the various pen kits I use. Anyone making theses bushing that I can contact? TIA

Gary

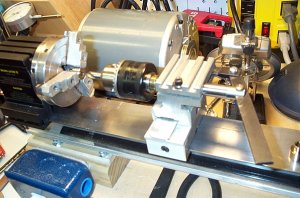

I am new to penturning and do all my turning between centers. Rick Herrel taught me a trick to adapt standard bushings to TBC bushings by adding the 60 degree chamfer. I used my Taig lathe for this but one could use any lathe for it with the right drill chuck. What is needed is a center drill and countersink bit (#4 or #5) to add a 60 degree chamfer to the large end of the bushing. See photos for details. Remember to use cutting oil.

My photos got reversed in order but you get the idea.I used a #5 drill and did not go deeper than 2/3 of the face of the bit.

I am new to penturning and do all my turning between centers. Rick Herrel taught me a trick to adapt standard bushings to TBC bushings by adding the 60 degree chamfer. I used my Taig lathe for this but one could use any lathe for it with the right drill chuck. What is needed is a center drill and countersink bit (#4 or #5) to add a 60 degree chamfer to the large end of the bushing. See photos for details. Remember to use cutting oil.

My photos got reversed in order but you get the idea.I used a #5 drill and did not go deeper than 2/3 of the face of the bit.

That idea is one I have used many times, although it just isn't the same thing, especially if the middle bushing which should be a 2 part bushing is a single part.

I am new to penturning and do all my turning between centers. Rick Herrel taught me a trick to adapt standard bushings to TBC bushings by adding the 60 degree chamfer. I used my Taig lathe for this but one could use any lathe for it with the right drill chuck. What is needed is a center drill and countersink bit (#4 or #5) to add a 60 degree chamfer to the large end of the bushing. See photos for details. Remember to use cutting oil.

My photos got reversed in order but you get the idea.I used a #5 drill and did not go deeper than 2/3 of the face of the bit.

That idea is one I have used many times, although it just isn't the same thing, especially if the middle bushing which should be a 2 part bushing is a single part.

So far I've not had a problem expanding the tubeI'm with ironman. If you're gonna TBC what's the point of using bushings? They're handy (and almost required) on the mandrel, but if you're gonna TBC you'll need bushings that will fit inside the tube so everything will remain centered. Again, what's the point of that? Get some calipers and eliminate the bushings.

Because measuring constantly is a pain in the butt.

There are also some good reasons to use bushings I think. One is no risk of expanding the brass tube. 2 is having a nice shoulder against the blank material. 3 is much better drive surface with 60 degree bevels on both the centers as bushings.

But in the end- for me - it's a matter of convenience.

I really dislike tbc without bushings.

For those that don't use them, good for you. Not for me.

Everything Dan said x 2

So far I've not had a problem expanding the tube-- maybe someday :frown:. The blanks occasionally slip a little, but seem to drive OK to get the job done.

Hi Smitty; Now I haven't gone back through the posts on this thread, but I don't recall any discussion with respect to their cost.I'm not overly sure that I fully understand all of the ado over bushings....they are relatively cheap and last quite a long time. TBC bushings are a little higher initial outlay but still don't add a lot of cost to a finished pen unless you're only going to do one or two.

That was a general comment, I had already posted (here or somewhere else to the same OP) regarding availability Including providing an IAP member name of a guy who makes them.Hi Smitty; Now I haven't gone back through the posts on this thread, but I don't recall any discussion with respect to their cost.I'm not overly sure that I fully understand all of the ado over bushings....they are relatively cheap and last quite a long time. TBC bushings are a little higher initial outlay but still don't add a lot of cost to a finished pen unless you're only going to do one or two.

The discussion I recall is availability now that johnnycnc has slowed down his production. Or did I miss something along the way?