mikeschn

Member

So I have a question about drive centers for my lathe...

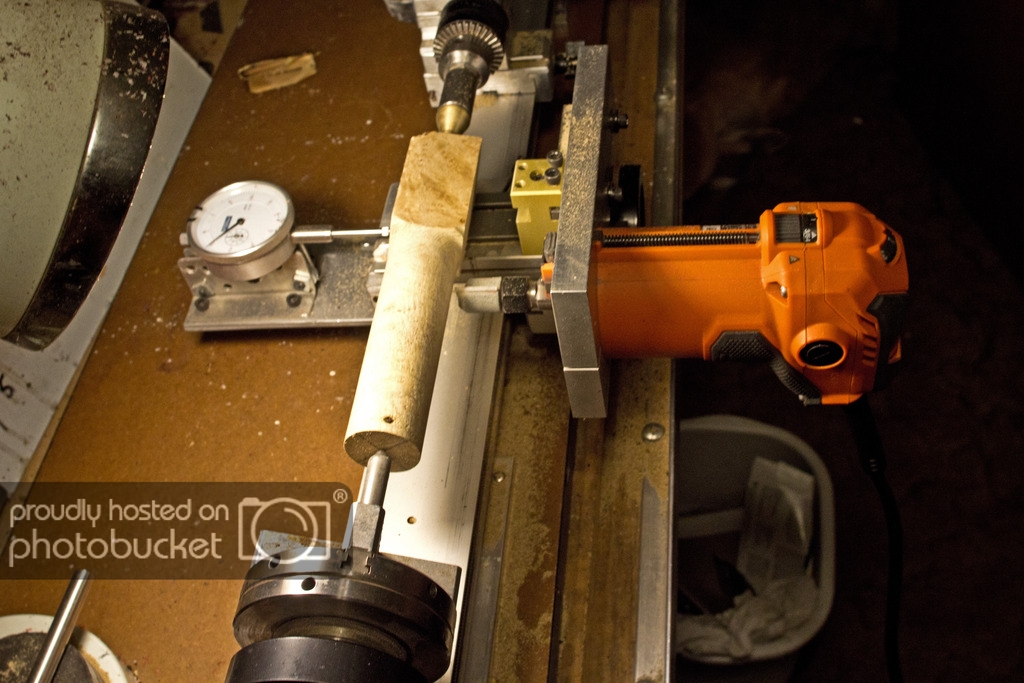

If I drill a hole all the way thru my square blank I can use a mandrel on a #2MT.

If I drill a hole part of the way thru my square blank (closed end) I can use a blind mandrel #2MT.

If I have no hole in my square blank, but want to turn the OD so that it fits into a Beall collet, would I use a drive center #2MT?

Mike...

If I drill a hole all the way thru my square blank I can use a mandrel on a #2MT.

If I drill a hole part of the way thru my square blank (closed end) I can use a blind mandrel #2MT.

If I have no hole in my square blank, but want to turn the OD so that it fits into a Beall collet, would I use a drive center #2MT?

Mike...