dozuki

Member

I think I have almost everything I am going to need to step into the kitless pen making world. I have several sets of taps and dies, collet chuck, chuck for rounding square blanks, nib sections and am ordering drills.

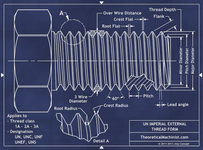

My question is are there special drills. I have been looking all over the net and it sounds like at least a few of the bits will be a little larger than needed. Like the 9X.75 works out to be a 8.25. So I am rounding up to 8.5mm. I just want to make sure that is how it works and I wont be getting drills that are just to big.

Thanks for the help. if anyone has any suggestions on tools that will make the process smoother I am open to suggestion.

My question is are there special drills. I have been looking all over the net and it sounds like at least a few of the bits will be a little larger than needed. Like the 9X.75 works out to be a 8.25. So I am rounding up to 8.5mm. I just want to make sure that is how it works and I wont be getting drills that are just to big.

Thanks for the help. if anyone has any suggestions on tools that will make the process smoother I am open to suggestion.