While this probably won't interest too many, some may find it actually useful? If you've ever thought about adding a 12v 3,500lb winch to the WoodWizer LT-28, in place of the hand crank 3,500lb winch....read on.

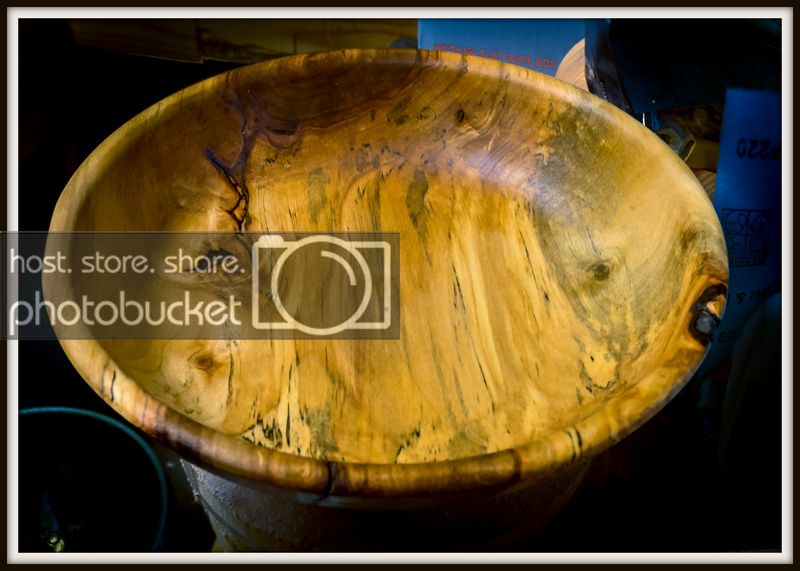

Guess I should tell folks, the only reason I'm doing this. I've just had my second back surgery in 6 years....and I am reducing the amount of effort required by 'me' in order to keep doing what I like doing! Even going as far to have a reduced rate for customer off-bearing on the mill so I don't have to do much of anything-other then walk back and forth with the mill head(and if I wanted, I could fix that at some point too).

We all know what a hand crank for the WM LT-28 looks like, okay, maybe some don't.....here it is. Unbolted and laying on a brace near the first unmoveable bunk plate.

Not much to look at, but for a healthy fella, this hand crank will load an extremely heavy log. I've personally brought a 32"diameter x 16'long piece(just for giggles, that's WoodWeb calc'd at 5,237lbs) of just dropped Southern Red Oak up the ramps using just this and some much hated bending and cranking in low range.

And this is a photo of where it comes from.

And another shot, showing the placement of what I call the "don't bend plate"(orange piece just in front of the black bracket). This 'plate' keeps the assembly from bending towards the mill main beam support....

The Warn Terra 3,500lb winch arrived! A little bigger then I had envisioned in my minds-eye while clicking on 'add to cart'....but it'll work. Just not in the horizonal I had hoped for due to the planetary gears(bottom of the photo). They would have had to hang to far under the support and thereby interferring with the main beam and mill carriage... So I'll have to mount it just as it is in the photo on the bracket I am making for the mill.

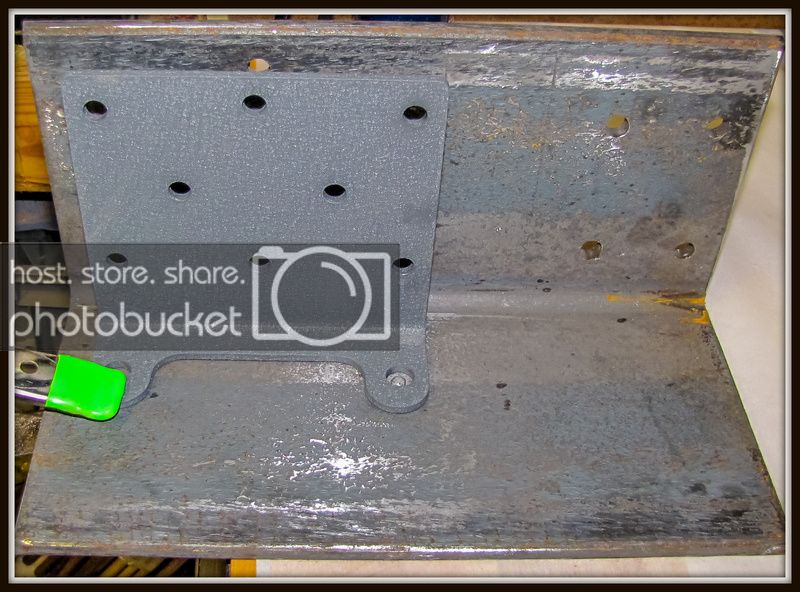

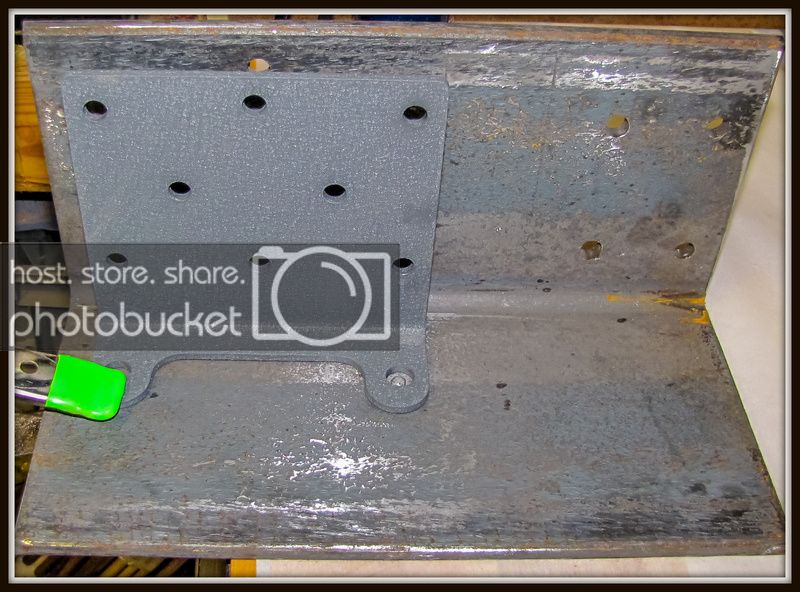

WoodMizer has a 'no weld' warranty. That pretty much means as soon as I touch the mill in anyway with a welding rod....poof, no more warranty. So to get around that small issue(because my mill is still really new), I am using a 6x6 piece of 5/16ths inch angle to bolt on and then bolt the winch to that. Here's an early mock-up of the angle....

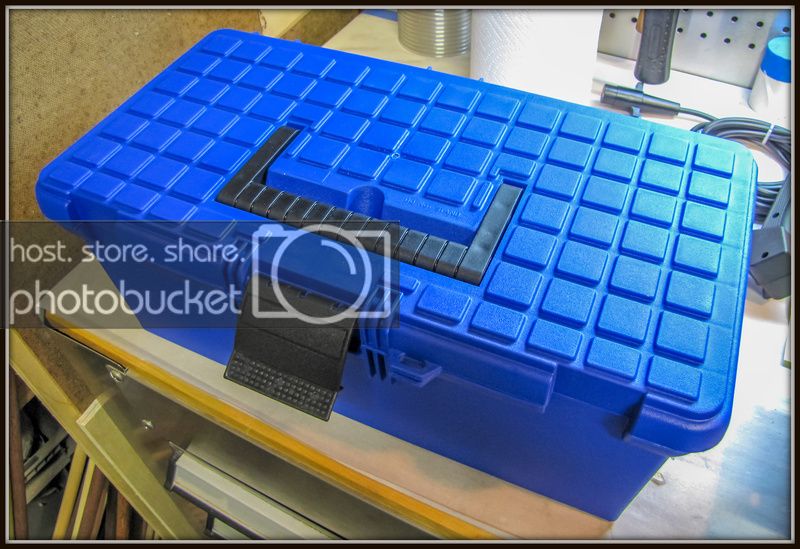

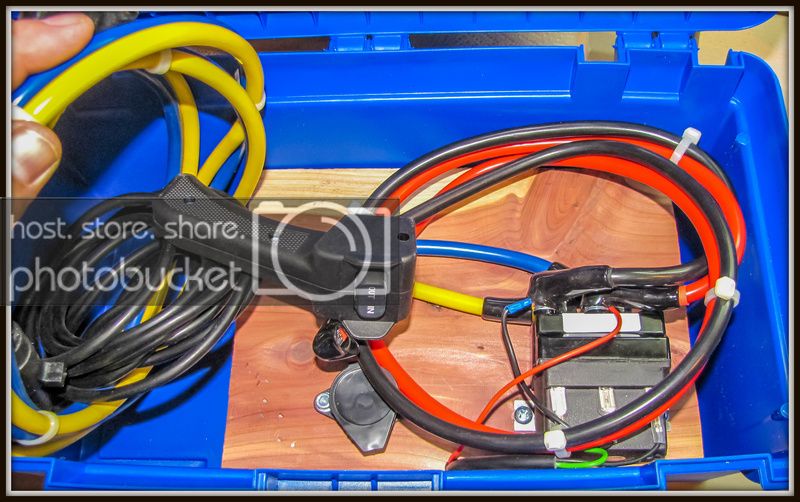

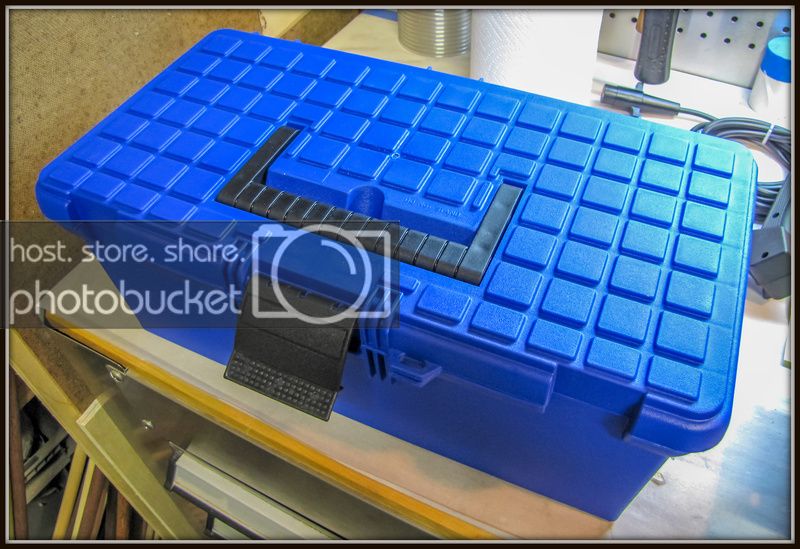

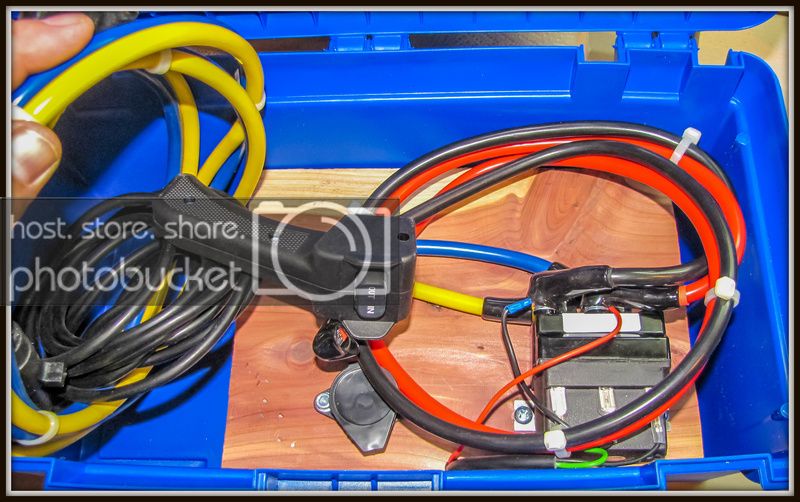

Now the Warn Terra 3500lb is actually sold as an 'ATV/UTV' winch...at least that is the crowd they are after. I can't image needing 3500lbs of winch to get an ATV un-stuck! But I guess if you are that stuck and a couple of snatch blocks on a 2000lb don't get it out....well, I guess it's stuck until the ground dries enough to get a trachoe in after it? The winch it's self is just part of the package...there is a ton of wiring for this thing. It comes with the ability to set-up as a handle bar thumb switch, a wired hand-control, and the solenoid has it's own big pile of necessary wiring. Since I'm not using the 'thumb mount', it can stay in the package.... So what to do with a bunch of wiring? Last thing you really want around a sawmill is a trip hazard(there's already enough). So I spent $7.53 and got this!

Grabbed a 1/4" thick piece of Eastern Red Cedar(it can be pretty), and mounted everything I was going to need on the board, made a little room under it to hide some wiring.....and BINGO! Got me a self-contained control box.

Got one more mock-up before I drill the last set of holes, and then I'll take all the stuff off the 6x6 angle, soak the angle in some vinegar(to scrape off the mill scale), then shot it with a few cans of black matte rattle can. Wait for that to dry and then mount everything up for good. I am using all grade #5 bolts and nuts, not too sure what WM uses for the bracket mount, but it looked sort of zinc covered(cheap)... Why not #8? Figured I'd rather they stretch some before they snap under strain(and maybe I'd see it before it happened......I'll be watching close on those first bunch of mid-sized logs....really close).

Until next time! After the rain...I'll have it on the mill and hopefully working?!?!?

Since it is raining for the next two days, I figured a few more coats of rattlecan can not hurt the steel angle. The mill scale pretty much came off with a rag after a 20hour soak in white vinegar....cleaned up real nice and pretty if I don't say. I then knocked any 'edges' off that would rip out clothing and such(human tissue) with a flappy thing of 80grit on the 4inch angle grinder too!

Just have to wait out the rain.....

Scott (got some time on my hands) B