Wasn't sure where to put this....here or the tool forum, but as I made it I guess it can go here:wink:

Just over 4 years ago this month I joined IAP and while cruising through the library I came across some really cool vids by Ed Davidson ( YoYoSpin )

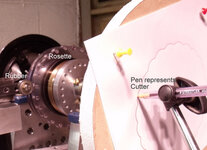

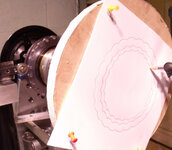

In one of his videos he was using a weird contraption that I found out was called a Rose Engine Lathe. I had never seen anything like it, but promised that it would be on my lengthy 'to-do' list.

So over the last few months I've been building this monstrosity:biggrin: from 99% scrap parts or tools I had already like the router and compound table.

This beast has two speeds from two motors. Under the table there is an old drill press motor that drives it at 1450 rpm. Between the sides of the machine is a small DC motor that drives a double worm gear arrangement to turn the spindle at a whopping 1 rpm ( yep, one rev per minute! )

( yep, one rev per minute! )

In these pics it is shown with my tailstock with a homemade spring loaded live centre. I threaded the spindle so it takes other chucks.

Still work to do making the 'rubbers'

The only parts I bought are the two collet chucks and the plumber block bearings. The rest comes from old electrical switchgear and even bits from an old bicycle.

I haven't actually used it yet, cos I'm having too much fun making the attachments for it.

So thanks Mr Davidson!!!!:biggrin:

Just over 4 years ago this month I joined IAP and while cruising through the library I came across some really cool vids by Ed Davidson ( YoYoSpin )

In one of his videos he was using a weird contraption that I found out was called a Rose Engine Lathe. I had never seen anything like it, but promised that it would be on my lengthy 'to-do' list.

So over the last few months I've been building this monstrosity:biggrin: from 99% scrap parts or tools I had already like the router and compound table.

This beast has two speeds from two motors. Under the table there is an old drill press motor that drives it at 1450 rpm. Between the sides of the machine is a small DC motor that drives a double worm gear arrangement to turn the spindle at a whopping 1 rpm

In these pics it is shown with my tailstock with a homemade spring loaded live centre. I threaded the spindle so it takes other chucks.

Still work to do making the 'rubbers'

The only parts I bought are the two collet chucks and the plumber block bearings. The rest comes from old electrical switchgear and even bits from an old bicycle.

I haven't actually used it yet, cos I'm having too much fun making the attachments for it.

So thanks Mr Davidson!!!!:biggrin: