CabinetMaker

Member

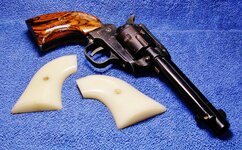

I decided that I wanted to do some silver inlay in my pistol grips. Since I am new to this, I figured I shouldn't jump right in on the grips that came with the guns so I decided to make my own. I had a piece of fairly uninteresting walnut laying around and decided to use that as my stock. It will also provide good contrast for the silver and brass inlay to come. If this makes a decent set of handles, I have a small chunk of Claro Walnut that will make a spectacular set of grips.

I took the grips off and looked closely at the one-piece construction. I decided that a two piece grip would be easier given the required tolerances.

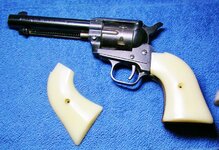

So I traced out some patterns, cut them out on the band saw and spent a while smoothing out the patterns so I could use it as a router guide. The larger pattern is the grip and the smaller pattern is the spacer. My idea is to actually glue the pieces together to make a one piece grip. I don't want the grip screw in my inlay field.

I built a couple of jigs to cut the butt to the proper length and a second to safely hold the grip during routing. U used a but of double sided tape to hold things firmly and it worked well. The extra length of the pattern allowed me to engage the guide bearing before the bit met the wood. This kept the router bit from grabbing the wood.

The next step was to taper the grips and that was a bit of a challenge. I thought about planer sleds, sander sleds and finally decided that the band saw would be easiest and safest, provided I could get my fingers away from the blade. So, more double sided tape and a little gig to properly support the blank while cutting.

It worked! And, I still have all 10 fingers.

No I have to start the hand shaping to make the grips fit both the gun and my hand. Once that is done, I will start working on the inlay.

The inlay will be a challenge as I must first make a set of push chisels from an old hack saw blade. Any advice from those that may hove done this or something similar?

Thanks for looking and have a great day.

I took the grips off and looked closely at the one-piece construction. I decided that a two piece grip would be easier given the required tolerances.

So I traced out some patterns, cut them out on the band saw and spent a while smoothing out the patterns so I could use it as a router guide. The larger pattern is the grip and the smaller pattern is the spacer. My idea is to actually glue the pieces together to make a one piece grip. I don't want the grip screw in my inlay field.

I built a couple of jigs to cut the butt to the proper length and a second to safely hold the grip during routing. U used a but of double sided tape to hold things firmly and it worked well. The extra length of the pattern allowed me to engage the guide bearing before the bit met the wood. This kept the router bit from grabbing the wood.

The next step was to taper the grips and that was a bit of a challenge. I thought about planer sleds, sander sleds and finally decided that the band saw would be easiest and safest, provided I could get my fingers away from the blade. So, more double sided tape and a little gig to properly support the blank while cutting.

It worked! And, I still have all 10 fingers.

No I have to start the hand shaping to make the grips fit both the gun and my hand. Once that is done, I will start working on the inlay.

The inlay will be a challenge as I must first make a set of push chisels from an old hack saw blade. Any advice from those that may hove done this or something similar?

Thanks for looking and have a great day.