Very nice Curtis!

I bought a Shark Pro Plus HD well over a year ago and I'm having a blast. I use mine for my hobbies and just because I enjoy making things out of wood. I have 5 grandkids so there's plenty of opportunities for me to make things. Now that I'm hooked I want to build a 4'x8' machine :biggrin:

VCarve Pro will do everything you need for your initial flat work. I recently upgraded to Aspire 4.0 and it's like VCarve Pro on steroids

. There literally isn't anything I can't do with it. I initially started out with the basic programs, VCarve pro, Cut 3D and Photo VCarve. The first two programs combined will do essentially what Aspire can but it's much more time consuming and labor intensive. Photo VCarve is still needed for scanned pictures and lithos.

If you decide you want or need Aspire you should still get a discount on the purchase 1 year from now since you purchased VCarve Pro.

Anyway, back to your build.

Are you going to use a router or spindle? Cost and longevity are a factor here. I would advise against a palm router, no power and not designed for plunge cutting. Depending on what you are going to use, check out Precise Bits. They have incredibly accurate collets for router bits, not to mention bits themselves. They also have charts for recommended bits, speeds & feeds.

I am using a Hitachi M12v 2.25 hp router. I am sure I will upgrade to a spindle some day but just could not do it now! I have a set of precisebitd collets on the way already!

Your table is the same size as the machine. I built mine twice as large as my machine to provide a place for my laptop and controller. I also built an enclosure with plexiglas windows to cut down on the noise and my dust collector is hooked up to the back. The HF dust collector is fine but it collects dust, not chips. You can get a new one for $150 with a coupon, that's what I did. I also added a Thein baffle and separator drum to it. You may get by with a dust shoe if you so desire. I made one but didn't like the fact I couldn't see the bit cutting and it interfered with some of my 3D work. We work with two different mediums but you are still going to make a mess, minus the dust.

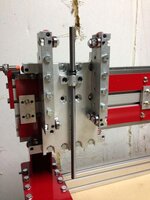

I will be putting the computer on a separate "cart" that I can move around to get out of the way, most likely. I did not want to use it on the base of the machine itself. For one, the rack and pinion system hangs down below the base of the machine so I would have to add risers to the wood base where the machine sets. I wanted everything integrated and stout so choose this route. Controllers and other electronics will go under the table. I will enclose this area with plywood and make doors for access and drawers for tooling. Of course the electronics will be enclosed with good fans to cool them.

I will be using a dust shoe from Kent CNC. It has brushes that are held in place with rare earth magnets and makes changing bits much easier. It is also clear acrylic. I am confident with a dedicated DC for just this machine blowing into a collection shack outside with no bags for pressure drop, I will get good results. I have working with dust collection a lot and have a system in my main shop that works very well that I designed.

As far as VCarve Pro, watch the tutorial videos, they are invaluable. Need any help, I can probably help.

I have had the trial version of VCarve Pro for two weeks now. I have watched all the tutorials and have already done a number of projects with it, just waiting on the machine to run them! While I was building, I designed and did the drafting for 98% of the 100 or so houses I built as well as a really cool church using parametric CAD software. I already think in 3-d and found VCarve very easy to use and figure out. We will see once the tool hits the material, though!

I'm sure you're already aware that besides the accuracy you get from cnc, it will allow you do be doing other things while it's cutting.

Like taking a nap as Bruce said above!

Welcome to the addition :biggrin: