pete00

Member

Howdy

We looked around for a table for our 3 season room, but didnt find any that fit right. Never having made a table of course i said ill make one. Search around for patterns and how tos.

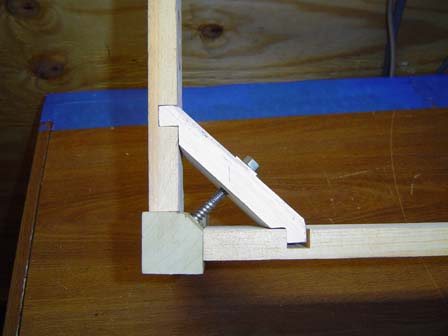

Came up with this test frame.

Of course i liked the corner brace in the bottom left, instead of the easy ones cut at 45d. Once i figured out what it was suppose to lool like it wasnt that hard. All cuts were 45d.

So i grabed some 1x6 pine and cut..cut ...cut...

Theres an extra grove by the corner brace, one of many oops.

The top is just screwed by the cleats in the back.

We wanted it to look a bit rustic so i left the planks with the gaps.

Put it together and this is what we got.

OF COURSE we didnt like the color, and we banged our knees on the apron. So i cut..cut...cut...and painted....didnt like the cut or the color...so i cut come more and painted over the first color.

Put it together and we got a keeper.

It about 36x33 x28"h

bet you think the story over right....nope

The legs are store bought because i couldnt make the legs.

HOWEVER look what came in the mail yesterday, my extention bed.

Looks like i can get a 36" piece in there

LOML now wants me to make her a desk.

now how do i make those legs...

We looked around for a table for our 3 season room, but didnt find any that fit right. Never having made a table of course i said ill make one. Search around for patterns and how tos.

Came up with this test frame.

Of course i liked the corner brace in the bottom left, instead of the easy ones cut at 45d. Once i figured out what it was suppose to lool like it wasnt that hard. All cuts were 45d.

So i grabed some 1x6 pine and cut..cut ...cut...

Theres an extra grove by the corner brace, one of many oops.

The top is just screwed by the cleats in the back.

We wanted it to look a bit rustic so i left the planks with the gaps.

Put it together and this is what we got.

OF COURSE we didnt like the color, and we banged our knees on the apron. So i cut..cut...cut...and painted....didnt like the cut or the color...so i cut come more and painted over the first color.

Put it together and we got a keeper.

It about 36x33 x28"h

bet you think the story over right....nope

The legs are store bought because i couldnt make the legs.

HOWEVER look what came in the mail yesterday, my extention bed.

Looks like i can get a 36" piece in there

LOML now wants me to make her a desk.

now how do i make those legs...