Is there enough material in the base to turn a tenon? If so, do that. Then use a chuck (either a fancy store-bought one or one you create on your lathe - called a jam chuck) to hold the bowl in the head stock. Using a low speed, turn away the nub inside the bowl. Then sand at a low speed too. Low speed is important because, without the support from the tail stock, the bowl can fly off and shatter when it hits the floor or other stuff in your shop. Once you get that nub turned away and the inside all sanded, I'd go ahead and finish the inside with whatever finish you choose. To get rid of the bottom tenon and sand and finish the bottom, use a face plate and make a convex piece from scrap wood that fits nicely inside the bowl. Place your bowl over the convex liece with a piece of leather or fabric between them. Bring us the tail stock and get it as centered as you can. This is often challenging, if you don't still have a little dimple from where you turned it in the first place. Once it's centered, turn away the tenon, shape your foot, sand and finish. You'll the center of the foot by hand when it's off the lathe, to get rid of the nub left from the tail stock holding it in place.

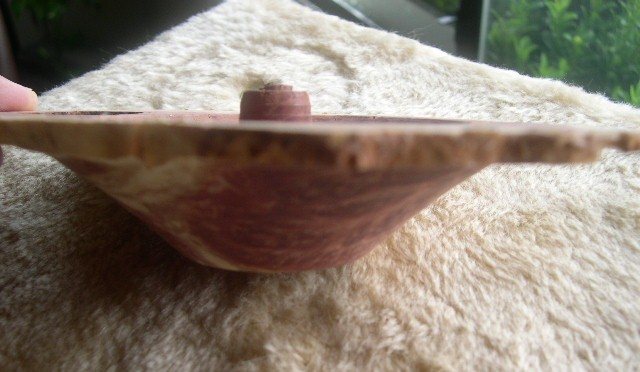

. After I finish cutting the inside of the bowl what is the best way to sand and finish this type of bowl? I think I like the shape so far I just need to finish the inside. I was also going to put a little lip on the inside where the bowl meets the wings. So if I could get your opinions that would be great.

. After I finish cutting the inside of the bowl what is the best way to sand and finish this type of bowl? I think I like the shape so far I just need to finish the inside. I was also going to put a little lip on the inside where the bowl meets the wings. So if I could get your opinions that would be great.