You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stablize blanks

- Thread starter Tim K

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Good write up Chris!!! I wish I'd had time to put up pic's but my results are as you described. I've done a few other types like aussie burl with a lot of rot, soft redwood, punky oak...you name it....works great!! I had the chance to chat with Curtis about stabilzing blanks then pressure casting those blanks as worthless wood. It works great!!

SantaEric

Member

does the ambient temp inside the shop affect the absorption inside the turntex chamber? Also, I've been sucking the air out for 2 1/2 hours and still have champagne bubbles...Is this good enough or should I cintinue to vaq until all bubbles are gone?

mikespenturningz

Member

I have had a great time with my system but lately I have been soaking my blanks in Cactus Juice with dye in it for a week at a time then cooking them. They are coming out great. If you don't have the funds to do both I would suggest that you simply get on Curtis's site, order a gallon of Cactus Juice, then get some dyes from him also while you are at it. Then get some small plastic containers and start right it. You can do a lot without the chamber it just takes longer. I do love my chamber though but it is not necessary to get started.

SantaEric

Member

and another set of Q's

Not sure where I heard it, but PR has a "flashpoint"??? so if the ambient temp in my shop is 60 and I mix some PR inside a box holding a pen blank and put it into my vac box, can I take it out and put it in the dutch oven to get the PR to cure? Or am I setting myself up for a big bang?

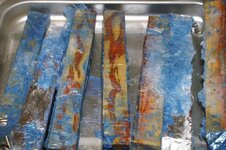

also, I included some pics of a test I did yesterday. I tried to dye some box elder with a blue mica powder mixed into the juice and then vac'd until bubbles 99% stopped then wrapped in foil and heated...this oven I guess went to about 225 to 230 degrees..and this is what came out. Did I overheat the wood or too fast or what? It looks like a lot of the juice was pushed out

(dried the wood for about 4 hours prior to juicing, and wood had moisture of 12% prior to drying)

Not sure where I heard it, but PR has a "flashpoint"??? so if the ambient temp in my shop is 60 and I mix some PR inside a box holding a pen blank and put it into my vac box, can I take it out and put it in the dutch oven to get the PR to cure? Or am I setting myself up for a big bang?

also, I included some pics of a test I did yesterday. I tried to dye some box elder with a blue mica powder mixed into the juice and then vac'd until bubbles 99% stopped then wrapped in foil and heated...this oven I guess went to about 225 to 230 degrees..and this is what came out. Did I overheat the wood or too fast or what? It looks like a lot of the juice was pushed out

(dried the wood for about 4 hours prior to juicing, and wood had moisture of 12% prior to drying)

Attachments

MesquiteMan

Retired Head Moderator

Eric,

Mica powder is NOT a dye and due to the size of the individual "grains" being larger than the pores of the wood, you will most likely not get much, if any, into the wood. Also, don't guess on the temp! Get an oven thermometer and check the oven temp. Don't rust the dial either. The temps you cured at are higher than the 200° the directions say and this will cause more of the resin to leak out of the blank. You are going to get some that leak out regardless, however. Also, 4 hours is NOT long enough to get 12% wood down to nothing. The crystalline cured resin I see in the pics is caused by moisture in the wood. Remember, 212° is the boiling point of water and when water boils, it turns to steam and expands. When it expands, it pushed resin out of the blank.

Try lowering your temps to the proper cure temp and make sure you wood is completely dry and you will get better results. Also use a dye rather than mica to color the wood.

Mica powder is NOT a dye and due to the size of the individual "grains" being larger than the pores of the wood, you will most likely not get much, if any, into the wood. Also, don't guess on the temp! Get an oven thermometer and check the oven temp. Don't rust the dial either. The temps you cured at are higher than the 200° the directions say and this will cause more of the resin to leak out of the blank. You are going to get some that leak out regardless, however. Also, 4 hours is NOT long enough to get 12% wood down to nothing. The crystalline cured resin I see in the pics is caused by moisture in the wood. Remember, 212° is the boiling point of water and when water boils, it turns to steam and expands. When it expands, it pushed resin out of the blank.

Try lowering your temps to the proper cure temp and make sure you wood is completely dry and you will get better results. Also use a dye rather than mica to color the wood.

mikespenturningz

Member

I have also found that you need a lot more dye than you think to get good color. I have followed Curtis's suggestions right from the start and have had very good success. He has already made most of the mistakes that can be made and he is more than open to help us to succeed which is a great thing and I truly thank you Curtis. Jump in and get started and have some real fun. It looks like you didn't use all that much dye in what you are showing images of. I found that I am putting 30 or more drops into a pretty small amount of Cactus Juice and getting thing quite dark to get good color.

SantaEric

Member

OK...message received and will apply, next Q

About how long at 200 degrees, do you need to dry wood that has a moisture reading from 8 to 12%. Denser woods vs softer woods but about how long? Also, am I going to **** off the wife if I use the kitchen oven to dry the wood? I have'nt noticed any odor from drying the wood but my schnoze might not be functioning correctly.

Can I put a kitchen cutting board mold inside the vac box? I made a pen blank sized mold and would like to put a piece of wood with boocoo voids in it and then use a craftin craft PR mixed with mica powder to create one of those really cool looking pen blanks.

BTW, curtis, bought one of those oven thermos so I know exactly where 200 degrees is now...just below the 150 setting....(made in china, I guess)

About how long at 200 degrees, do you need to dry wood that has a moisture reading from 8 to 12%. Denser woods vs softer woods but about how long? Also, am I going to **** off the wife if I use the kitchen oven to dry the wood? I have'nt noticed any odor from drying the wood but my schnoze might not be functioning correctly.

Can I put a kitchen cutting board mold inside the vac box? I made a pen blank sized mold and would like to put a piece of wood with boocoo voids in it and then use a craftin craft PR mixed with mica powder to create one of those really cool looking pen blanks.

BTW, curtis, bought one of those oven thermos so I know exactly where 200 degrees is now...just below the 150 setting....(made in china, I guess)

SantaEric

Member

one other thing

having done the process once (not drying the wood all the way and not usuing a dye) can I get a do over? Can I dry the wood some more, resink it in some resin mixed with dye and vac it/bake it??? or do I have some more outside firewood?

having done the process once (not drying the wood all the way and not usuing a dye) can I get a do over? Can I dry the wood some more, resink it in some resin mixed with dye and vac it/bake it??? or do I have some more outside firewood?

The Penguin

Member

my experiences...

About how long at 200 degrees, do you need to dry wood that has a moisture reading from 8 to 12%. I've baked all my woods for about 24 hours at 200º Denser woods vs softer woods but about how long? Also, am I going to **** off the wife if I use the kitchen oven to dry the wood? probably not. but you will if you use the kitchen oven to heat cure the Cactus Juice and it leaks out and spills in the oven. I have'nt noticed any odor from drying the wood but my schnoze might not be functioning correctly.

Can I put a kitchen cutting board mold inside the vac box? I made a pen blank sized mold and would like to put a piece of wood with boocoo voids in it and then use a craftin craft PR mixed with mica powder to create one of those really cool looking pen blanks.

BTW, curtis, bought one of those oven thermos so I know exactly where 200 degrees is now...just below the 150 setting....(made in china, I guess)

mikespenturningz

Member

I purchased a cheap toaster oven at Walmart onsale and it works great. I would not use an oven that I intended to eat from. I use much lower temps for actually drying woods I use like 125 for so. I use a thermometer so I can be sure about what I am doing. I am not sure what temp will or could cause wood to combust that is why I use lower temps. I only cook for about 1 hour when I am done stabilizing though! I also use a thermometer when doing that. I usually don't use tin foil. My oven has a catch basin so the Juice doesn't get to the burner. Just my way..

MesquiteMan

Retired Head Moderator

My comments in red below:

I purchased a cheap toaster oven at Walmart onsale and it works great. I would not use an oven that I intended to eat from. I use much lower temps for actually drying woods I use like 125 for so. I use a thermometer so I can be sure about what I am doing. I am not sure what temp will or could cause wood to combust that is why I use lower temps. The flash point for most wood is 525° F so as long as it is not touching the element, it will not burn at low temps such as 200° I only cook for about 1 hour when I am done stabilizing though! This is fine if you are doing pen blanks. However, if you start doing larger pieces or more pieces at a time, you cure time will go up. One hour is NOT a good blanket recommendation since if you take it out and let it cool down and find that it has not cured, you have just wasted that piece of wood since it will not cure properly the second time. Remember, it takes 6-8 minutes at 200° F to polymerize the resin. The issue is, however, that you must get the internal temp of the wood up to 200° and that takes some time. The amount of time is dependent on thickness of the wood, how much wood, and even the density of the wood. I would rather see folks be on the safe side and cook for 2 hours than to see wasted wood! I also use a thermometer when doing that. I usually don't use tin foil. My oven has a catch basin so the Juice doesn't get to the burner. Just my way..

MesquiteMan

Retired Head Moderator

having done the process once (not drying the wood all the way and not usuing a dye) can I get a do over? Can I dry the wood some more, resink it in some resin mixed with dye and vac it/bake it??? or do I have some more outside firewood?

By all means, dry it out and run it again! You can stabilize the wood numerous times if you want. That is one of the ways of doing double dyed blanks as well.

mikespenturningz

Member

One thing I have found is if I cook too long I feel that the color fades? Do you have any thoughts on this Curtis? I forgot some wood in the oven once and it stayed in all day. Most of the color at least on the outside was very subdued.

mikespenturningz

Member

My comments in red below:

I purchased a cheap toaster oven at Walmart onsale and it works great. I would not use an oven that I intended to eat from. I use much lower temps for actually drying woods I use like 125 for so. I use a thermometer so I can be sure about what I am doing. I am not sure what temp will or could cause wood to combust that is why I use lower temps. The flash point for most wood is 525° F so as long as it is not touching the element, it will not burn at low temps such as 200° I only cook for about 1 hour when I am done stabilizing though! This is fine if you are doing pen blanks. However, if you start doing larger pieces or more pieces at a time, you cure time will go up. One hour is NOT a good blanket recommendation since if you take it out and let it cool down and find that it has not cured, you have just wasted that piece of wood since it will not cure properly the second time. Remember, it takes 6-8 minutes at 200° F to polymerize the resin. The issue is, however, that you must get the internal temp of the wood up to 200° and that takes some time. The amount of time is dependent on thickness of the wood, how much wood, and even the density of the wood. I would rather see folks be on the safe side and cook for 2 hours than to see wasted wood! I also use a thermometer when doing that. I usually don't use tin foil. My oven has a catch basin so the Juice doesn't get to the burner. Just my way..

Sorry Curtis I have been cooking for about an hour all along and it works for me. I don't use any tin foil maybe that is why but an hour seem to get it done for me. I do check to make sure everything is solid. I am getting ready to get my 3rd gallon so it's not like I have not been cooking a bit.

Last edited:

MesquiteMan

Retired Head Moderator

Sorry Curtis I have been cooking for about an hour all along and it works for me. I don't use any tin foil maybe that is why but an hour seem to get it done for me. I do check to make sure everything is solid. I am getting ready to get my 3rd gallon so it's not like I have not been cooking a bit.

And if it works for you, that is all the matters my friend! I am just hesitant to suggest an hour since I have had thicker pieces take longer and so have other customers. My fear, based on previous customer issues, is that if 1 hour is suggested, they may just toss them in for one hour and then take them out and let them cool without checking them. Then, when they open the foil, they find liquid and then the blanks are ruined since they will not properly polymerize the second time. For new stabilizers, it is just safer to recommend a longer time to ensure success.