panchos61

Member

I already like your page from long time ago thanks

Sent from my iPhone using Penturners.org mobile app

Sent from my iPhone using Penturners.org mobile app

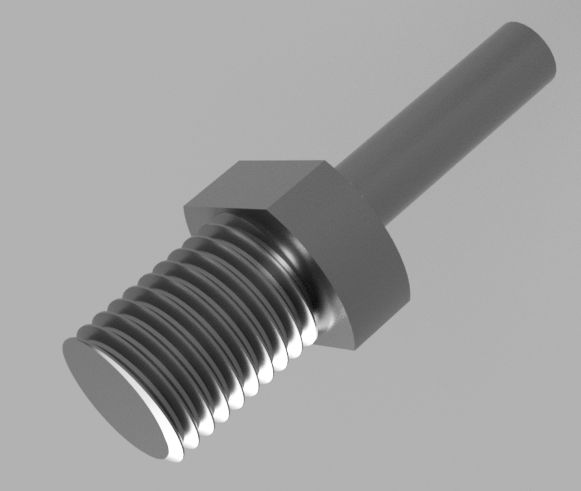

Can you make one of these?

https://www.woodturnerscatalog.com/p/72/7070/Artisan-Ring-Turning-Chuck

I have been waiting for 2 months for them to get more in stock, but they still can't give me a date.

Not that hard, I would price that like my Spindle Thread Adapters. Those are $40 but since this doesn't have any interior threading I guess $30 would be about right.

What is it for? If I knew that maybe there's something made commercially that would be cheaper for you.

PM me with your response.

Rick, I would like to order the sanding jig. Not sure how to proceed.

Hey Rick, I love my offset sanding jig so much I'm back for more. I would like to order the 17pc. SET of TUBE SLEEVES for the sanding mill (I already have the sanding mill). Thanks in advance!

Hi Rick,

I need to order a couple of pin chucks - One for 3/8" tubes and one for 10mm tubes. Please PM with cost + shipping and your PayPal address. Thanks.

Hello

I would like your sanding mill 2.0 to please.

Thanks

Sent from my iPhone using Penturners.org mobile app

Hi, Rick I would like a 9" rest with a 5/8ths post 4.5 high. Harbor Freight lathe.

I will pay by pay pal send me your address. Thanks Mike