JasonC

Member

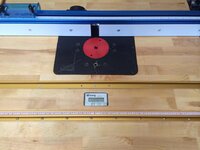

When I got my lathe April 11th this is where I stuck it - on the kids' workbench.

I have a 8' fluorescent in the garage and three LED spot lights so I can direct light where I need it, but with the garage door up one of the LEDs (the one above the dartboard) was blocked by the door. I wanted better lighting so I could more easily see scratches and low spots during finishing so I came up with a solution.

Tonight I started working on a contained, better lit spot for this lathe. Used some 3/4" and 1/2" MDF I had left over from a car audio project and picked up some melamine to laminate the interior portion with. Also grabbed a 2' dual-tube T5 fluorescent that's rated for 2400 lumens. The front will have a lexan shield on a piano hinge.

Raw MDF

And with melamine rough cut and stuck in place.

Will laminate everything tomorrow then break it down and send each piece through the router to flush trim before final assembly.

I have a 8' fluorescent in the garage and three LED spot lights so I can direct light where I need it, but with the garage door up one of the LEDs (the one above the dartboard) was blocked by the door. I wanted better lighting so I could more easily see scratches and low spots during finishing so I came up with a solution.

Tonight I started working on a contained, better lit spot for this lathe. Used some 3/4" and 1/2" MDF I had left over from a car audio project and picked up some melamine to laminate the interior portion with. Also grabbed a 2' dual-tube T5 fluorescent that's rated for 2400 lumens. The front will have a lexan shield on a piano hinge.

Raw MDF

And with melamine rough cut and stuck in place.

Will laminate everything tomorrow then break it down and send each piece through the router to flush trim before final assembly.