VisExp

Member

I've been using a lot of wood veneers in my segmenting lately. Initially I was cutting the veneers with a utility knife and ruler. I decieded I needed something more accurate and efficient. When I think accurate and efficient, I often think of my table saw. :biggrin:

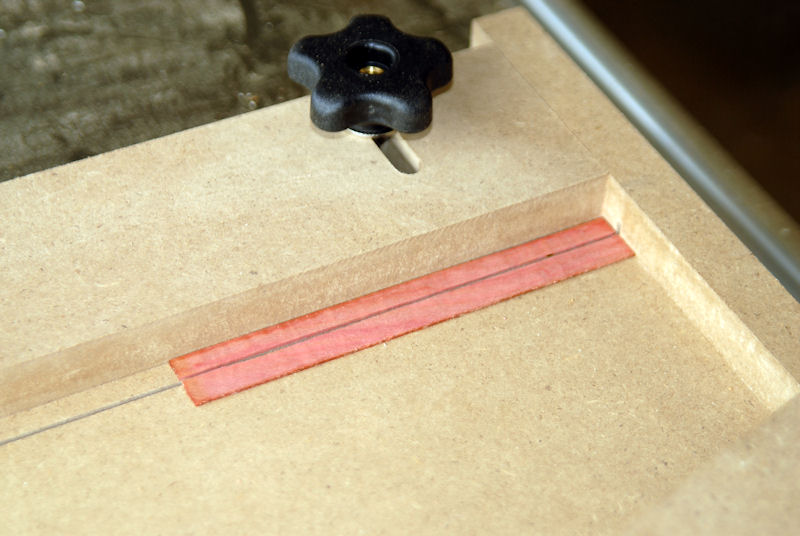

The following pictures show what I came up with. The jig has a runner which fits in the miter slot. A couple of points when building the jig:

The following pictures show what I came up with. The jig has a runner which fits in the miter slot. A couple of points when building the jig:

- Assemble the base, leading and trailing edges first. When attaching the leading and trailing edges don't use any metal attachments (brad nails or screws) in the area where the blade cut will be.

- Attach the runner. Make sure the runner fits snugly in the miter slot with no play.

- Raise the blade 1". I used 3/4" MDF so this meant the blade would be 1/4" higher than the bed of the jig.

- Run the bed through the saw. You now have a cut line in the bed of the base which is perfectly parallel to the miter slot without any measuring

- Add the jig fence and hold down block with a handle. Make sure the screws attaching the handle of the hold down jig are well offset to the cut line! The bed of my jig will accept a piece of veneer just over 12" long. I made the fence so that I could rip/crosscut a piece of veneer up to 2"

- A good coat of wax on the base of the jig and runner will help it to glide smoothly.