I posted initial thoughts on my (then) new 12" Turncrafter two days after I unpacked it in 2013. After almost four years, I can add some additional points. Let me hasten to say that my overall impression is still very positive - this is a good machine. I made a decision to buy this lathe after a very careful comparison of four different midis (the 12" Turncrafter, the Delta 46-460, the Jet 1221, and a Nova). I created a spreadsheet that listed the specifications of these four machines so that I could clearly see how that stacked up against each other. Frankly, there was a personal factor that was important to me (footprint - I wanted to use with an existing bench), so other people could see the same comparison and draw different conclusions. That said, Fine Working Magazine did rate the 12" Turncrafter as a best buy in its comparison of midi-lathes.

Having used the machine for almost four years, I have developed a few opinions. Most are picky issues that really don't amount to very much - things that one can easily learn to work with or around.

1. The base of the tailstock is very slightly smaller than the gap between the bedways, resulting in a tendency for the tailstock to twist. Normally this is not an issue, but it can cause some sloppiness when drilling. The solution is simple - use a skew to turn a very slight dimple in the workpiece, and center the bit on that dimple before locking down the tailstock.

2. There is an indexing feature that I rarely use. It is tempting to use it as a spindle lock, but it's not designed for that purpose. The indexing wheel is plastic, and using it as a spindle lock will cause teeth to break off that wheel (DAKHIKT). Others have also had this experience, and there is a

YouTube video showing how to replace the wheel. Presumably, PSI sells replacement wheels as repair parts. By the way, they also sell replacement belts (they come in a set of two) - they are not in the catalog and you have to call customer service. I bought a pair just in case, but I've not had to replace a belt yet.

3. The speed range 'out of the box' is fine for ordinary turning, and it is a very simple matter to tweak the range if you want to do something specialized (such as thread-chasing).

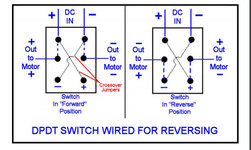

4. There is no reversing function, and there is a hack for that also.

5. If you tighten a chuck too much, its hard to remove because there is no spindle lock, I have found that a channel lock wrench can be used on the hub of the handwheel to apply additional torque to help break loose a stuck chuck. A better solution would be to modify the design to have hole in the spindle so that the knockout bar can be used to apply additional torque to break loose a stuck chuck.

6. Like many midi lathes, the motor is directly below the bedways. The result is that sawdust and woodchips collect on top of the motor. I have a small brush that fits between the bedways that I used to knock off the accumulated sawdust. One has to be careful about applying finishes to a piece on the lathe because of the tendency for the finish to drop down on top of the motor, essentially gluing sawdust onto the motor housing.

7. If the set screw that locks the tailstock ram is loosened too much, the ram can twist in its housing. Then, if you try to tighten the lock, it will catch the edge of the channel machined into the ram leaving nicks that then cause the ram to bind as it moves in or out of the tailstock. The solution is to periodically disassemble the tailstock and use a file to clean up the edge of the channel.

8. The 12" Turncrafter comes with two tool rests. I use the shorter rest far more than the longer rest (just the nature of what I do), but the shorter rest is still sometimes too long, and PSI doesn't offer a shorter aftermarket rest. One option is to contact Rick Herrell; another is a shop-made rest.

9. There is an access door in headstock to get to the lower pulley. This access door has closure that involves a black knob that attaches to a spring-loaded screw. Unfortunately, that knob can easily become detached from the screw and fall into the shavings on the floor under the lathe where it disappears forever (DAMHIKT either). I had to make a replacement knob by embedding a nut in a turning - it's large enough, and is light in color so it won't get lost.

By the way, the King Canada 1218 lathe sold in Canada appears to be the same machine only painted a different color.

Bottom line - for the money, this is a very good lathe.