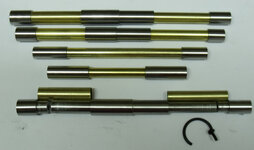

Here's what I've been working on for the last few days.:biggrin:

As I've got a metal lathe, it would be silly not to make my own bushes and stuff. But I wanted to go a step further than just making them a bit more accurate than stock bushings. Here are the changes I made...

1. Make them out of stainless steel. This would make them last longer, be more rigid, and less 'black' crud while wet sanding.

2. The outside 'finished' diameter to be long enough to be held in a chuck, but also 60deg end drilled for turning between centres. Also so that a special short tool rest isn't needed.

3. The inside portion(s) to almost fill the tube. This keeps the blank square even if the ends of the blank aren't pefectly squared. This works particularly well with pre-cast tubed blanks. Even if the ends are way off square, it is held parallel to the tube. Once the outside of the blank is made parallel to the tube, it is easy to re-chuck the blank and square the ends with a scraper or skew.

4. With capped pens, there is a flat surface to take a rubber o-ring to make closed ended pens. ( Like my old design )

I've made them for the Baron series ( Baron, Sedona, Navigator, Typhoon ), Jr series ( Gent, Statesman, Retro ) , Sierra (Click and Original), Aero, and Long Clicker.

I've made 3 sets so far, 1 has been spoken for, I'm keeping the first ( rough:redface set and the last set 'could' be up for grabs here if there is enough interest. Watch this space:wink: Just waiting for a technological breakthrough solution by our trusty leaders:biggrin:

set and the last set 'could' be up for grabs here if there is enough interest. Watch this space:wink: Just waiting for a technological breakthrough solution by our trusty leaders:biggrin:

If my lathe was CNC, then I'd also offer them for sale, but it's hard boring work so I'll just periodically make a set and just offer them for a trade for stuff.

LOL, just remember when you see these elsewhere, :wink: :tongue: who made them first!!!.:biggrin: Copyright my a.....!!!:biggrin:

:tongue: who made them first!!!.:biggrin: Copyright my a.....!!!:biggrin:

As I've got a metal lathe, it would be silly not to make my own bushes and stuff. But I wanted to go a step further than just making them a bit more accurate than stock bushings. Here are the changes I made...

1. Make them out of stainless steel. This would make them last longer, be more rigid, and less 'black' crud while wet sanding.

2. The outside 'finished' diameter to be long enough to be held in a chuck, but also 60deg end drilled for turning between centres. Also so that a special short tool rest isn't needed.

3. The inside portion(s) to almost fill the tube. This keeps the blank square even if the ends of the blank aren't pefectly squared. This works particularly well with pre-cast tubed blanks. Even if the ends are way off square, it is held parallel to the tube. Once the outside of the blank is made parallel to the tube, it is easy to re-chuck the blank and square the ends with a scraper or skew.

4. With capped pens, there is a flat surface to take a rubber o-ring to make closed ended pens. ( Like my old design )

I've made them for the Baron series ( Baron, Sedona, Navigator, Typhoon ), Jr series ( Gent, Statesman, Retro ) , Sierra (Click and Original), Aero, and Long Clicker.

I've made 3 sets so far, 1 has been spoken for, I'm keeping the first ( rough:redface

If my lathe was CNC, then I'd also offer them for sale, but it's hard boring work so I'll just periodically make a set and just offer them for a trade for stuff.

LOL, just remember when you see these elsewhere, :wink: