W.Y.

Member

As I was discussing this jig in a couple Segmented Turning boards on the internet that were geared primarily to segmented bowls and vessels etc, I got thinking that some people have done segmented work on pens as well and I also have although I previously did them on my table saw.

This is patterned from the one that I watch Malcolm Tibbets using in one of his DVD's .

He prefers this way over a table saw sled but he does show both ways and how to make a sled as well.

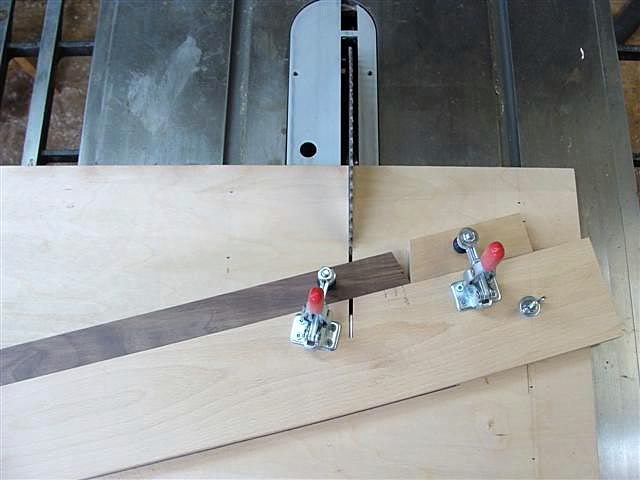

Here is a picture showing all of it .

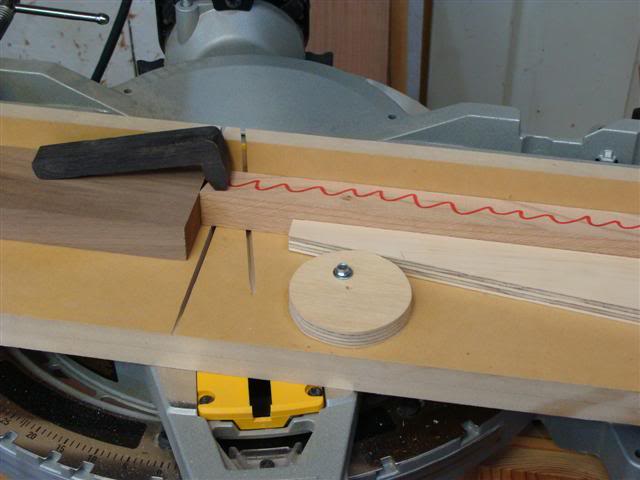

Below shows the right side of the blade with the wedge and disc that holds the strip against the fence. Notice the hole purposely drilled off center in the disk so it tightens the wedge against the wood being cut.

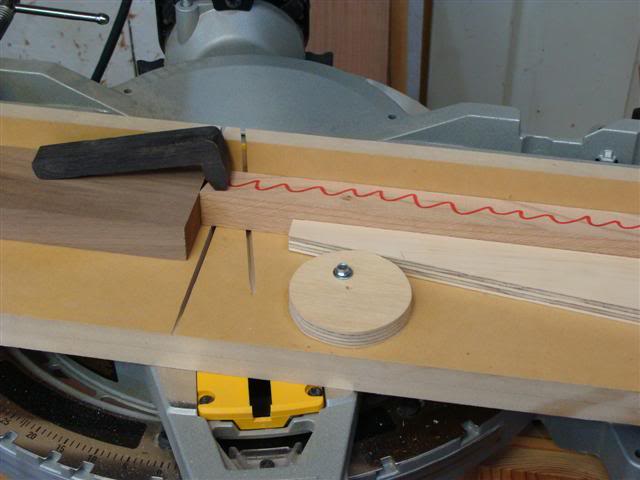

Here is the left side shown with the blade in the down position. That little black tool is held by the left hand on top of the segment for safety reasons probably so there is no chance of the segment moving and causing a jamb or kickback although I cut quite a few segments before I made that little holder while I was fine tuning my segment angle and didn't have a problem.

I just used an ebony pen blank to make the tool and now that I have it I will get in the habit of using it.

I think where the tool comes in place mostly is if a person raises the blade while it is still spinning which could possibly lift up on the segment.

I have found that turning the saw off at the bottom of the cut for each one works very well and probably more safely . The blade brake is real good on that saw it really doesn't take all that much longer.

This is patterned from the one that I watch Malcolm Tibbets using in one of his DVD's .

He prefers this way over a table saw sled but he does show both ways and how to make a sled as well.

Here is a picture showing all of it .

Below shows the right side of the blade with the wedge and disc that holds the strip against the fence. Notice the hole purposely drilled off center in the disk so it tightens the wedge against the wood being cut.

Here is the left side shown with the blade in the down position. That little black tool is held by the left hand on top of the segment for safety reasons probably so there is no chance of the segment moving and causing a jamb or kickback although I cut quite a few segments before I made that little holder while I was fine tuning my segment angle and didn't have a problem.

I just used an ebony pen blank to make the tool and now that I have it I will get in the habit of using it.

I think where the tool comes in place mostly is if a person raises the blade while it is still spinning which could possibly lift up on the segment.

I have found that turning the saw off at the bottom of the cut for each one works very well and probably more safely . The blade brake is real good on that saw it really doesn't take all that much longer.