OK, trying again

For the last few days I have been playing around with pin chucks and trying to come up with a simpler method of making one that anyone could do even on a wood lathe.

Pin chucks, for those that aren't familiar with them are one of many tools or methods that are used to hold items for turning, that dont have a hole all the way through. Of course, we use them for closed ended pens.

The first time I even heard of them was right here on IAP. So I'm not claiming to have invented anything.

Pin chucks can be made in minutes if you have a metal lathe and milling facilities. I'm lucky and do have them. But most penturners don't, so here is a way to make one out of stainless steel on your wood lathe. You will never have to hunt for that tiny thin pin again!!!

Ok, take one long bolt that is as close in size to your chosen pen kit tube as possible. I chose this bolt for the longest kit I had. This bolt is 8mm x 120mm Stainless Steel

Now cut the hex head off with a hacksaw and square up the end with a file.

If you have a Centre Drill use it, or like here, just use a nice and sharp 4 0r 5mm drill to about 5 -6mm deep. A thinner drill may flex and skate over the stainless.

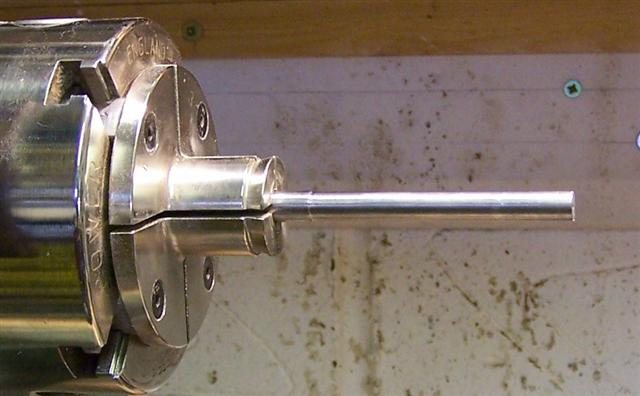

Most scroll chuck jaws are numbered. Put a reference mark on the bolt in line with the number 1 jaw.

Put the bolt in the chuck and bring up the tailstock. Note that I'm not trying to clamp on the threads. Select a length approx 3/4 the length of the tube and make a mark on the bolt.

You don't want to wreck the jaws, so stack some washers upto the mark.

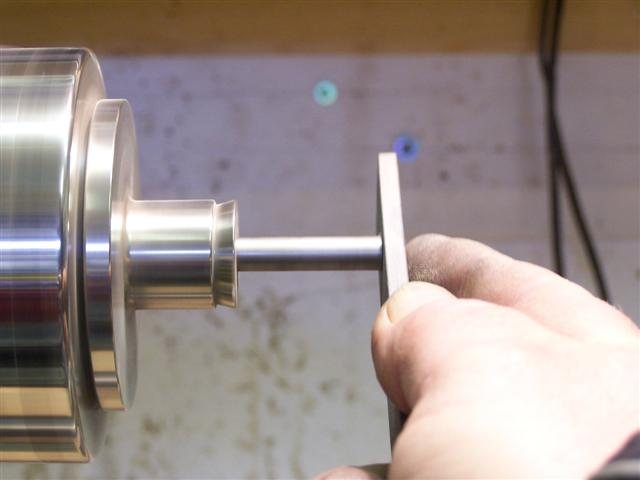

Measure the inside diameter of the tube. I have actually stretched the tube slightly with the caliper. the actual measurement is 7.26mm for this tube. Lock the caliper in this stretched position.

Now the fun part!!! Hold a good clean file in the LEFT HANDED method

and with the lathe on quite slow, go for it. Stroke the file left to right in smooth circles. It goes pretty quick so keep checking with the caliper. Use a sharpie to mark any high areas. As the file does not leave the surface, you don't have to worry at all about the washers.

Once the caliper goes over the bolt throughout its length, you can remove the tailstock. Now change to about 240 grit wet'n'dry and use get the brass tube to fit as snug as you can. Use the sharpie and start from the end. It should look like this.

Now some more 'fun'

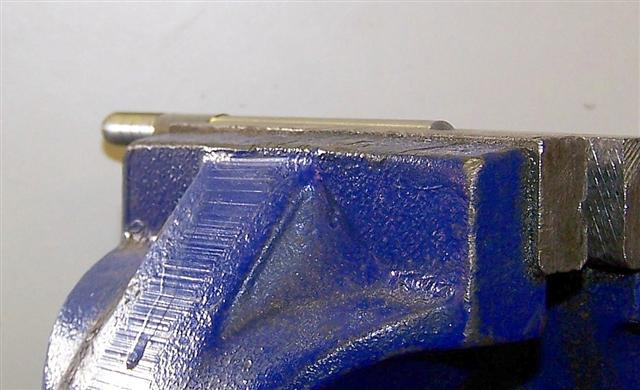

Mount the bolt in your vice like this. Take some time to do this. Make it protrude from the jaws by approx 2mm. When you are happy it is parallel to the jaws, clamp it up real tight. I tried to use jaws gaurds but it just popped out. But my vice is a bit worn. No big deal at all. Any marks can just be sanded down later.

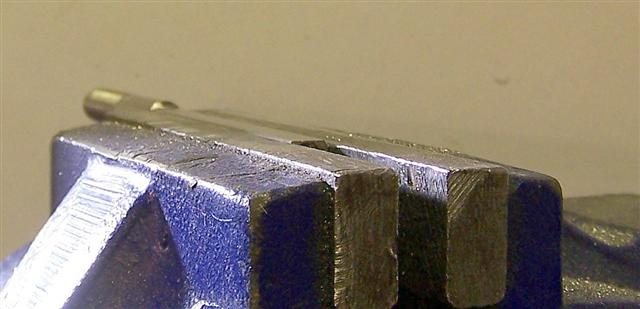

Now file a flat down to the jaws. You will soon see how flat you are filing by following the lines.

File a flat chamfer on the end. I also filed a round groove but it's not needed.

Now the magic bit. Take a small o-ring and cut it. Tie a knot on one end. O-rings are dirt cheap.

Hold the o-ring over the chamfer like this and offer up the tube.

It helps if you wet the o-ring a bit ( I just licked it )

I had to mount in the lathe to get it on the rest of the way. You can just see the end of the o-ring. The tube ( when you have a blank on it) will of course go all the way to the shoulder. You can also slide a correct bushing on first. I rarely use bushes. Mount it in the chuck with marks aligned every time you use it. If your blank is square, I suggest using the tailstock till you have it round. If your wood is pretty soft then just put a small washers between the revolving tailstock centre and the blank. Works great.

Here you can see why I didn't cut the threads off. I tapped a aluminium tube with the same thread ( 8mm ) and made a handle for buffing As you can see, I am putting looooooooong knurls on everything ( Thanks Joe )

As you can see, I am putting looooooooong knurls on everything ( Thanks Joe )

So, there you have it.

The finished pen

I hope someone trys this as it took much longer to do this pictorial than it took to make the o-ring chuck and the pen!!!!!

For the last few days I have been playing around with pin chucks and trying to come up with a simpler method of making one that anyone could do even on a wood lathe.

Pin chucks, for those that aren't familiar with them are one of many tools or methods that are used to hold items for turning, that dont have a hole all the way through. Of course, we use them for closed ended pens.

The first time I even heard of them was right here on IAP. So I'm not claiming to have invented anything.

Pin chucks can be made in minutes if you have a metal lathe and milling facilities. I'm lucky and do have them. But most penturners don't, so here is a way to make one out of stainless steel on your wood lathe. You will never have to hunt for that tiny thin pin again!!!

Ok, take one long bolt that is as close in size to your chosen pen kit tube as possible. I chose this bolt for the longest kit I had. This bolt is 8mm x 120mm Stainless Steel

Now cut the hex head off with a hacksaw and square up the end with a file.

If you have a Centre Drill use it, or like here, just use a nice and sharp 4 0r 5mm drill to about 5 -6mm deep. A thinner drill may flex and skate over the stainless.

Most scroll chuck jaws are numbered. Put a reference mark on the bolt in line with the number 1 jaw.

Put the bolt in the chuck and bring up the tailstock. Note that I'm not trying to clamp on the threads. Select a length approx 3/4 the length of the tube and make a mark on the bolt.

You don't want to wreck the jaws, so stack some washers upto the mark.

Measure the inside diameter of the tube. I have actually stretched the tube slightly with the caliper. the actual measurement is 7.26mm for this tube. Lock the caliper in this stretched position.

Now the fun part!!! Hold a good clean file in the LEFT HANDED method

and with the lathe on quite slow, go for it. Stroke the file left to right in smooth circles. It goes pretty quick so keep checking with the caliper. Use a sharpie to mark any high areas. As the file does not leave the surface, you don't have to worry at all about the washers.

Once the caliper goes over the bolt throughout its length, you can remove the tailstock. Now change to about 240 grit wet'n'dry and use get the brass tube to fit as snug as you can. Use the sharpie and start from the end. It should look like this.

Now some more 'fun'

Mount the bolt in your vice like this. Take some time to do this. Make it protrude from the jaws by approx 2mm. When you are happy it is parallel to the jaws, clamp it up real tight. I tried to use jaws gaurds but it just popped out. But my vice is a bit worn. No big deal at all. Any marks can just be sanded down later.

Now file a flat down to the jaws. You will soon see how flat you are filing by following the lines.

File a flat chamfer on the end. I also filed a round groove but it's not needed.

Now the magic bit. Take a small o-ring and cut it. Tie a knot on one end. O-rings are dirt cheap.

Hold the o-ring over the chamfer like this and offer up the tube.

It helps if you wet the o-ring a bit ( I just licked it )

I had to mount in the lathe to get it on the rest of the way. You can just see the end of the o-ring. The tube ( when you have a blank on it) will of course go all the way to the shoulder. You can also slide a correct bushing on first. I rarely use bushes. Mount it in the chuck with marks aligned every time you use it. If your blank is square, I suggest using the tailstock till you have it round. If your wood is pretty soft then just put a small washers between the revolving tailstock centre and the blank. Works great.

Here you can see why I didn't cut the threads off. I tapped a aluminium tube with the same thread ( 8mm ) and made a handle for buffing

So, there you have it.

The finished pen

I hope someone trys this as it took much longer to do this pictorial than it took to make the o-ring chuck and the pen!!!!!