watch_art

Member

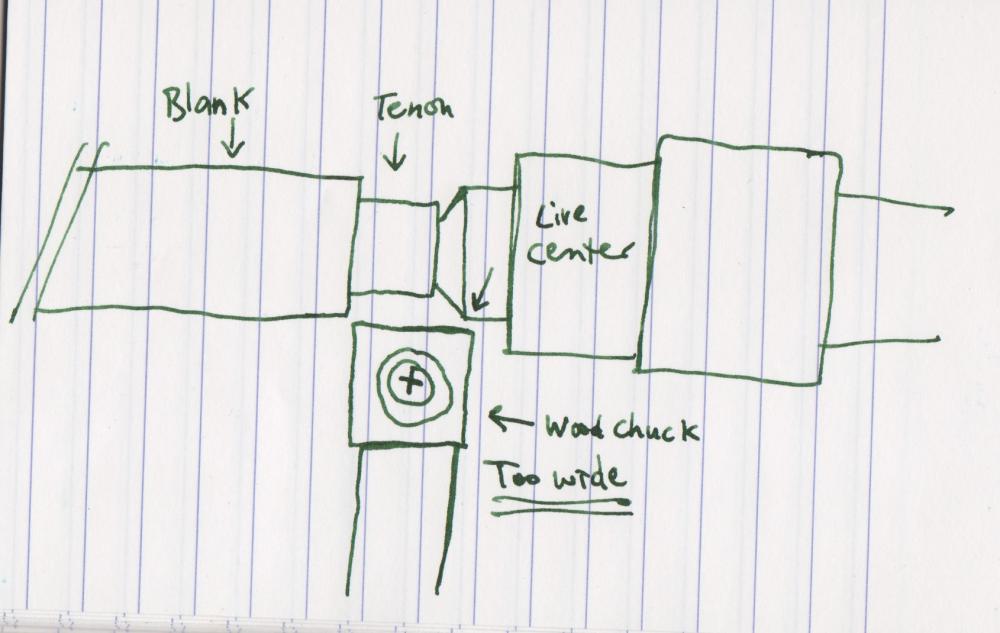

I have one of your bog standard wood lathe parting tools. Wooden handle with hss tip (that broke off during first use - but sharpened the nub b/c it was better that way).

I'm past the bit of hss that was left and have only a bit of flat steel that I try putting an edge on to use as a parting tool.

It seems like a big waste of time.

Could I use this instead?

1/8"MICRO-100 BOUBLE SIDED SUPER CARBIDE PARTING BLADE | eBay

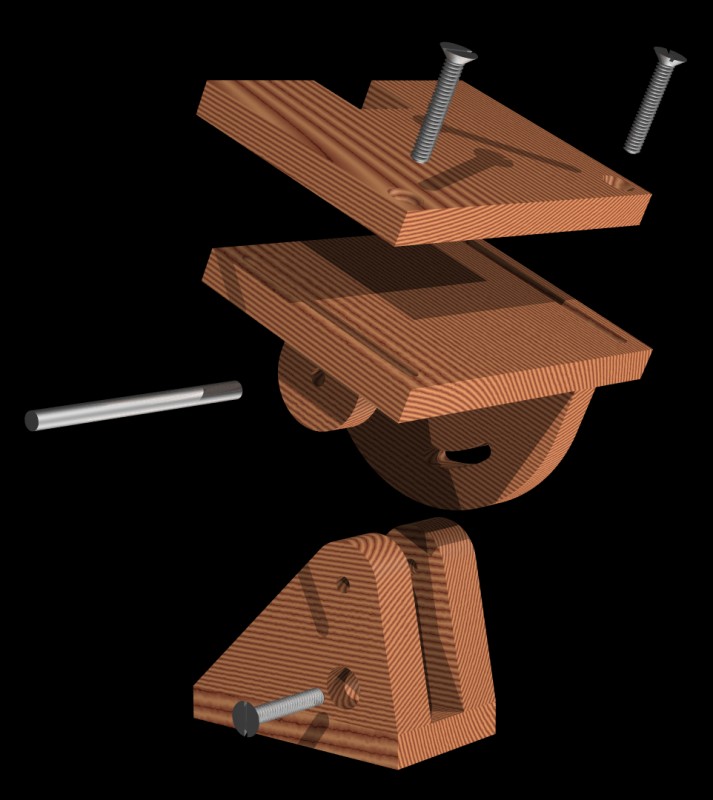

I need something that I won't have to sharpen. I'm horrible at sharpening things. I may as well use a hammer to sharpen my turning tools. I love my woodchuck with the carbide tips - I'd be DELIGHTED if there were anything about 2-3mm wide that I could attach to my woodchuck and use it as a parting tool.

Any advice - BESIDES learn to sharpen?

:biggrin:

Thanks!

I'm past the bit of hss that was left and have only a bit of flat steel that I try putting an edge on to use as a parting tool.

It seems like a big waste of time.

Could I use this instead?

1/8"MICRO-100 BOUBLE SIDED SUPER CARBIDE PARTING BLADE | eBay

I need something that I won't have to sharpen. I'm horrible at sharpening things. I may as well use a hammer to sharpen my turning tools. I love my woodchuck with the carbide tips - I'd be DELIGHTED if there were anything about 2-3mm wide that I could attach to my woodchuck and use it as a parting tool.

Any advice - BESIDES learn to sharpen?

:biggrin:

Thanks!