joshua_luther77

Member

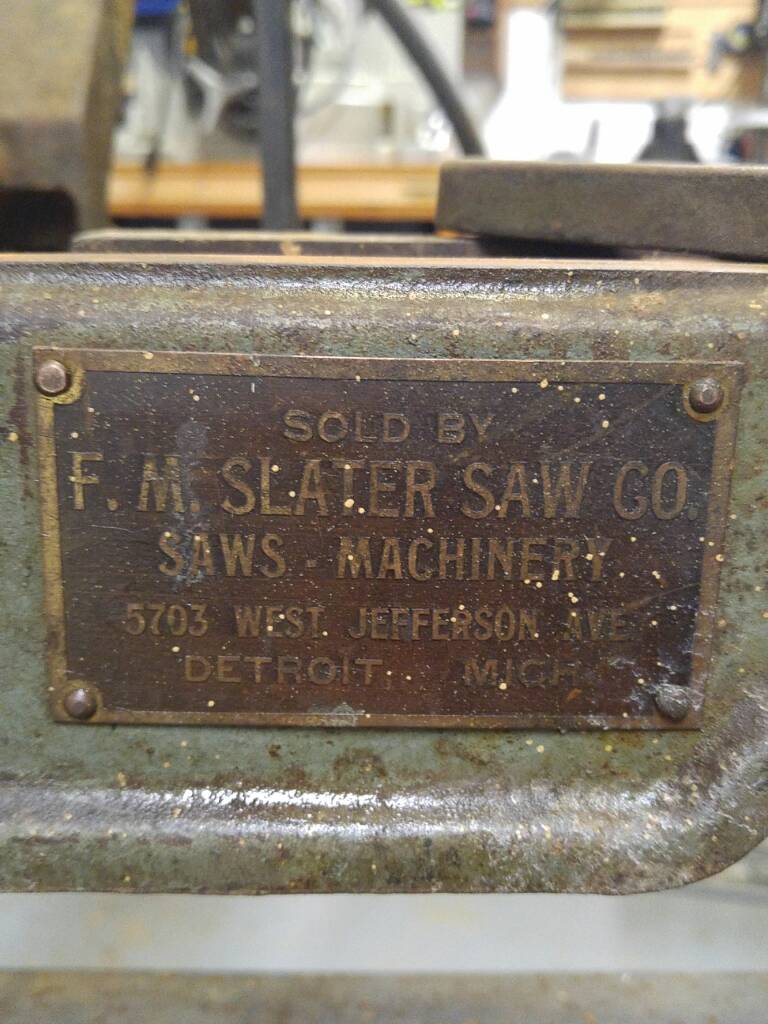

I just picked up this lathe today off Craigslist. This is my first lathe and am excited to get into turning. I'm not sure what brand it is and was wondering if anyone here knew anything about this company or has any idea what brand it is.

I'd also like to know how to find out what size Morse taper I have. I really don't want to jerry rig it work. The spur center is missing the point. The wheel to turn the shaft on the tail stock doesn't turn shaft toward the middle. I have to bump it forward into the wood.

Sent from my VS986 using Tapatalk

I'd also like to know how to find out what size Morse taper I have. I really don't want to jerry rig it work. The spur center is missing the point. The wheel to turn the shaft on the tail stock doesn't turn shaft toward the middle. I have to bump it forward into the wood.

Sent from my VS986 using Tapatalk