JimB

Member

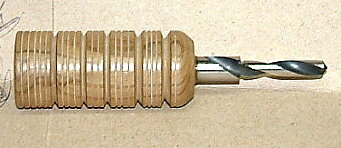

I know there have been several threads on squaring blanks and also cleaning up the ends of a finished blank to get the excess CA or other finish off the blank. I still use a pen mill when I have a lot of trimming to do but I use this home made set up for taking off just a little wood or for removing that annoying bit of CA on the ends after finishing the blank. I was to cheap to buy another gadget and didn't have the patience to make sure my disc sander table was square to the disc. So I made this. I already had everything except the hex nut (1 X 8 for my Jet). It is just like what many do on the disc sander but is on the lathe. I like this a lot because it is quickly removed and is always square when mounted again.

This was very easy to make. I roughed the hex nut with sandpaper and glued (thick CA) it to a scrap piece of wood. I also ran a bead of CA around the hex nut / wood joint and sprayed with accelerator (I didn't want to get it glued to my headstock). I mounted it on the lathe and knocked off the corners. Then I trued the surface using a fingernail bowl gouge in a scraper position. This was the most time consuming part but still only took a few minutes. I placed my Jacobs chuck in the tailstock with a punch from my HF set. The little black square on the wood is the sandpaper. It is held in place using turners tape. I make these in strips a little wider than the tape and cut them into squares. I make the strips in several different grits.

To use just slide a blank onto the punch and slide the tailstock up so the punch is close to the sandpaper. Turn on lathe and slide the blank into the sandpaper while holding it against the punch. It's so easy I don't bother locking the tailstock. I just hold it with one hand and slide the blank with the other. A few seconds and the excess CA is removed. The sandpaper peals right off and is quickly replaced.

This was very easy to make. I roughed the hex nut with sandpaper and glued (thick CA) it to a scrap piece of wood. I also ran a bead of CA around the hex nut / wood joint and sprayed with accelerator (I didn't want to get it glued to my headstock). I mounted it on the lathe and knocked off the corners. Then I trued the surface using a fingernail bowl gouge in a scraper position. This was the most time consuming part but still only took a few minutes. I placed my Jacobs chuck in the tailstock with a punch from my HF set. The little black square on the wood is the sandpaper. It is held in place using turners tape. I make these in strips a little wider than the tape and cut them into squares. I make the strips in several different grits.

To use just slide a blank onto the punch and slide the tailstock up so the punch is close to the sandpaper. Turn on lathe and slide the blank into the sandpaper while holding it against the punch. It's so easy I don't bother locking the tailstock. I just hold it with one hand and slide the blank with the other. A few seconds and the excess CA is removed. The sandpaper peals right off and is quickly replaced.

![DSCF0001 [].JPG](/data/attachments/14/14493-a738ed3efafb1cf7c644f21d0ba2e9bd.jpg)