Dale Allen

Member

Anyone here get involved in any of the small hobby sized CNC mini milling machines?

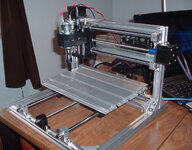

I got one of the 2418 models that is a DIY set. Kinda like a big boy's erector set. It tried my patience but I got it together. Only has a 7" x 4" working area and the depth is about 1.5". I have wanted for years to better understand the CNC control of machines and I figured this would be a less expensive way to learn. Later I can move to a bigger machine that can do more serious stuff.

I got one of the 2418 models that is a DIY set. Kinda like a big boy's erector set. It tried my patience but I got it together. Only has a 7" x 4" working area and the depth is about 1.5". I have wanted for years to better understand the CNC control of machines and I figured this would be a less expensive way to learn. Later I can move to a bigger machine that can do more serious stuff.