I love carbide in CNC machines.

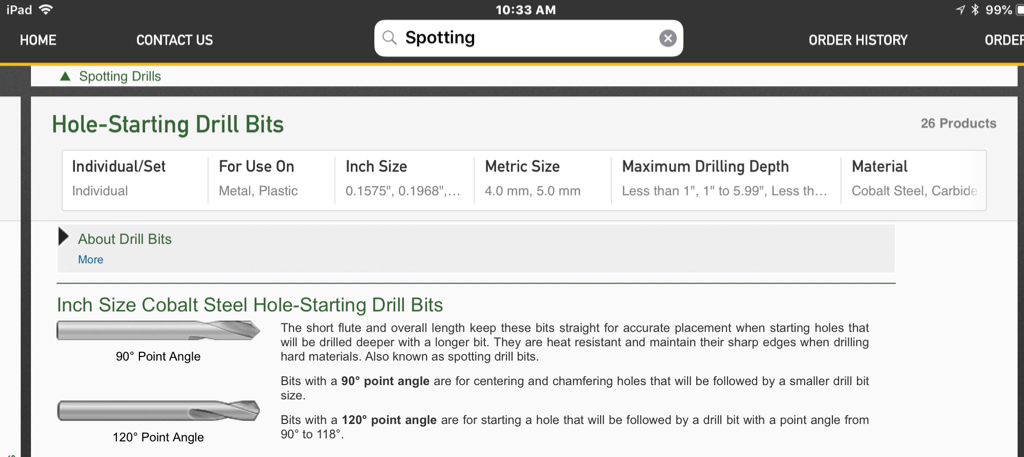

I have had very very poor experience with carbide in manual machines. Both in one-off work I have done myself and in watching set-ups done for small volume runs. Carbide needs to be fed very smoothly at the correct rate and the machine settings must also be correct. It is simply too brittle for most operators. It is very difficult to feed smoothly and not get those impact stresses on the leading edge.

The scenario above seems to be an example where the stress could be amplified.

Running carbide into soft wood or acrylic would not be as problematic, but there are limited benefits, especially for a hobbyist. There are thousands of grades of carbide and the ones marketed to woodworkers are generally on the lower end of the spectrum. When I worked in a shop that used very expensive HSS drills, I salvaged a bunch out of the scrap bucket and resharpened. They work extremely well. They resharpen better than carbide. The chance of a chip from impact of some sort is much less.

If you had someone running a drill press for an 8 or 10 hour shift making a repetitive operation in wood a good carbide drill might make sense to me. Either way I think your stoppages will be to clean the bit, not sharpen it, so it wouldn't matter what material was used.

I would suggest anyonehaving trouble drilling perform the calculations for their tools and materials and make sure their machine is on the correct speed. One of my pet peeves is when I go into someones shop and they just drill everything on the same RPM. A 5/8 drill should not be run at the same speed as a 5mm. You can often get away with it in wood, but it is hard on the tools, causes burns in the wood, and other issues. In metal it just isn;t possible to do so. The machine will crash.