Czarcastic

Member

Blank “Rounding†Jig

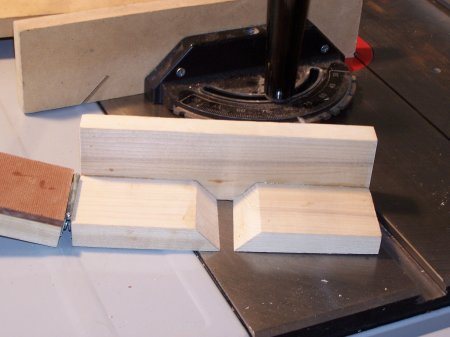

When turning synthetics (corian, acrylics, PR, etc), its easier and safer - not to mention less wear on your turning tools â€" to start with a blank with the sides rounded off. This also reduces the risk of blow-out on the edges when “roughing-out†your blank.

The easiest way to do this is on the bench sander.

Unfortunately, it’s not always easy to hold the blanks in your hand without sanding off several layers of skin, or occasionally watching the blank slip from your hands and use your bench sander as a launching catapult to go careening across your workshop.

I built this simple jig out of scrap wood. This jig provides a very safe and effective way to help hold the blank on the sanding belt, and to provide the most efficient angle to make short work of “chamfering†your blank.

You will need:

About 16†of scrap 1x4 hardwood. (I used poplar)

(cut into 1-6†piece, and 1 6-3/8†piece)

A 6â€-8†piece of hardboard

A small hinge

The construction is simple.

1) Cut a 6†piece of hardwood from your 14†piece

2) Cut a 45° miter along the 1†side

3) Glue the edges of the two mitered pieces to a 6-3/8†piece of hardwood so the hardwood is at 90° to the mitered edges and the “throat†of the miters is about 3/8†apart (photo)

4) Rout a “V†groove into a 4†piece of hardwood and then cut a 45 miter on each side so you end up with a “Wâ€

5) Sit the “W†into the “V†of the jig, and glue a 6†piece of harboard to it (photo)

6)glue the remaining small piece of hardwood to the left edge for the hardboard, and attach a hinge.

Your blank fits in like this: Notice the amount protruding from the throat:

7) Lightly press down on the hardboard as you run the sander, until the blank is flush to the bottom of the jig

8) Rotate until each edge has been sanded.

The result is a blank that is chamfered on all sides, and ready for the lathe.

Note: I rarely use this for wood, I only used wood for demo purposes. This jig was made for when I turn synthetic (acrylic and corian) pens.

-Steven Marlow

When turning synthetics (corian, acrylics, PR, etc), its easier and safer - not to mention less wear on your turning tools â€" to start with a blank with the sides rounded off. This also reduces the risk of blow-out on the edges when “roughing-out†your blank.

The easiest way to do this is on the bench sander.

Unfortunately, it’s not always easy to hold the blanks in your hand without sanding off several layers of skin, or occasionally watching the blank slip from your hands and use your bench sander as a launching catapult to go careening across your workshop.

I built this simple jig out of scrap wood. This jig provides a very safe and effective way to help hold the blank on the sanding belt, and to provide the most efficient angle to make short work of “chamfering†your blank.

You will need:

About 16†of scrap 1x4 hardwood. (I used poplar)

(cut into 1-6†piece, and 1 6-3/8†piece)

A 6â€-8†piece of hardboard

A small hinge

The construction is simple.

1) Cut a 6†piece of hardwood from your 14†piece

2) Cut a 45° miter along the 1†side

3) Glue the edges of the two mitered pieces to a 6-3/8†piece of hardwood so the hardwood is at 90° to the mitered edges and the “throat†of the miters is about 3/8†apart (photo)

4) Rout a “V†groove into a 4†piece of hardwood and then cut a 45 miter on each side so you end up with a “Wâ€

5) Sit the “W†into the “V†of the jig, and glue a 6†piece of harboard to it (photo)

6)glue the remaining small piece of hardwood to the left edge for the hardboard, and attach a hinge.

Your blank fits in like this: Notice the amount protruding from the throat:

7) Lightly press down on the hardboard as you run the sander, until the blank is flush to the bottom of the jig

8) Rotate until each edge has been sanded.

The result is a blank that is chamfered on all sides, and ready for the lathe.

Note: I rarely use this for wood, I only used wood for demo purposes. This jig was made for when I turn synthetic (acrylic and corian) pens.

-Steven Marlow