leehljp

Member Liaison

I have 3 replaceable carbide bladed chisels and numerous HSS bladed ones.

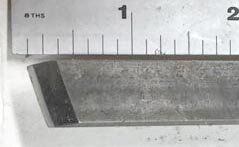

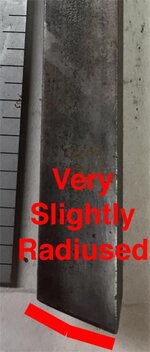

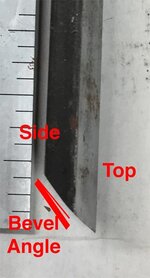

I made my own favorite chisel from a rounded HSS scraper. Basically I ground it on a water wheel to a shape similar to a blunt (square) end but with about 10° angle because I am right handed.

I love the continued sharpness of my carbide but I get the finest cuts with my home made HSS. I keep a glass plate with 4 strips of psa micro sandpaper next to my lathe and swipe the blade every minute or two. To me, it stays sharper than I get with any new carbide blade replacement.

Yet, I read on this forum how sharp the carbides are and how well they cut. I haven't purchased any replacement blades in the last 4 years, so technology may have improved. And I remember a thread on this about 5 or 6 years ago in which the grain of carbide was discussed and it was mentioned that it was not as fine as HSS could achieve. Has this changed?

I would appreciate a discussion on this from the "technical" perspective. Thanks

I made my own favorite chisel from a rounded HSS scraper. Basically I ground it on a water wheel to a shape similar to a blunt (square) end but with about 10° angle because I am right handed.

I love the continued sharpness of my carbide but I get the finest cuts with my home made HSS. I keep a glass plate with 4 strips of psa micro sandpaper next to my lathe and swipe the blade every minute or two. To me, it stays sharper than I get with any new carbide blade replacement.

Yet, I read on this forum how sharp the carbides are and how well they cut. I haven't purchased any replacement blades in the last 4 years, so technology may have improved. And I remember a thread on this about 5 or 6 years ago in which the grain of carbide was discussed and it was mentioned that it was not as fine as HSS could achieve. Has this changed?

I would appreciate a discussion on this from the "technical" perspective. Thanks