Hey Folks:

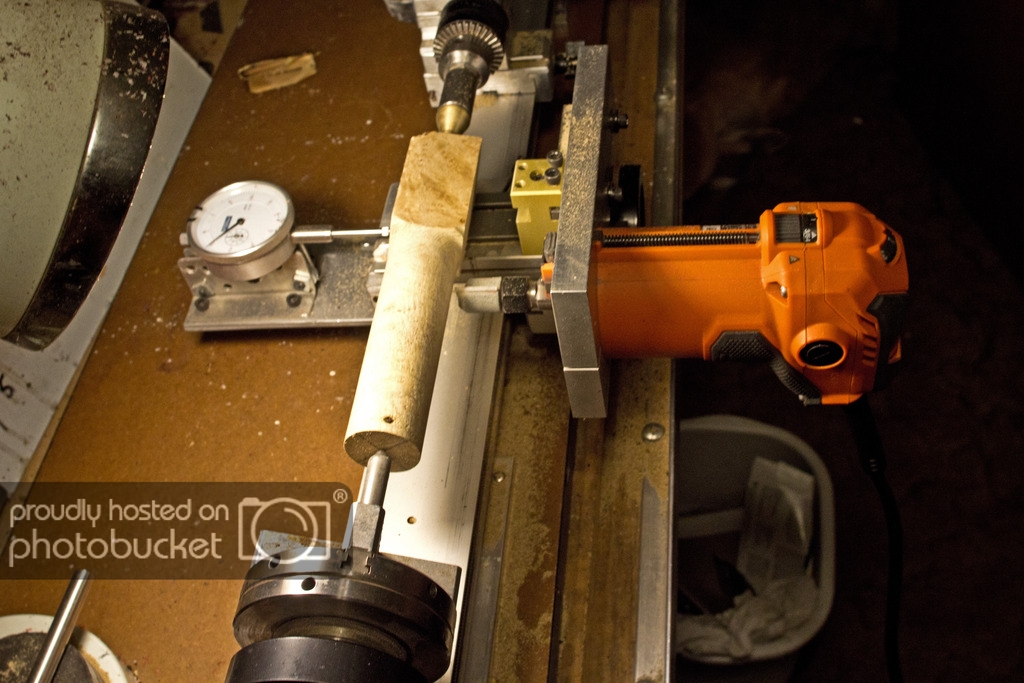

I don't use a mandrel. I do use TBC bushings as well as the non-TBC bushings to turn between centers. I don't really have any trouble with the non-TBC (PSI or the like bushings), but I thought these centers may add some stability and possibly even truer turning. I wonder about the quality of these centers given the relatively low price.

If you use them, I would like to know what you think.

Turning Between Centers Mandrel System MT#2: Arizona Silhouette=

Thanks!

I don't use a mandrel. I do use TBC bushings as well as the non-TBC bushings to turn between centers. I don't really have any trouble with the non-TBC (PSI or the like bushings), but I thought these centers may add some stability and possibly even truer turning. I wonder about the quality of these centers given the relatively low price.

If you use them, I would like to know what you think.

Turning Between Centers Mandrel System MT#2: Arizona Silhouette=

Thanks!