BCnabe

Member

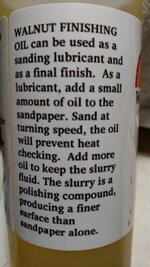

Several months ago I started using walnut oil for the last step of sanding to help fill in the grain. I've liked and it does pop the grain nicely.

At about the same time I switched to using Mercury CA (thin and medium flex - M20FT and M300FM) and accelerator.

I've been happy overall with the finish I'm getting but I've had more issues since making this switch with the CA delaminating from the blank near the bushings.

Here's my process: turn the blank; sand up to 400; sand with 400 and walnut oil; let it set for at least 24 hours and then CA.

Typically I will do 4 coats of thin, 4 coats of medium and then 4 coats of thin. I'll also do some light sanding (600 grit) after each stage to keep the finish smooth and to get rid of any ridges that might show up. After that I'll micromesh and buff.

At different stages of applying CA I will snap the bushings off. For years this worked fine but after making the switch I started getting small chips delaminating from the blank - I could see raw wood.

I've tried scoring the blank/bushing joint with a razor blade but that hasn't always helped either. Last night as I was scoring the joint I could see the CA turn white (delaminating) on both the blank and the bushing as I was scoring it. When I took the bushings off the CA was flaking off of the bushing and I had a couple of places on the blank that had bare wood.

I'm wondering if the walnut oil is possibly a culprit - not getting good adhesion between the wood and CA.

This has happened with different species - walnut, leopardwood, osage orange.

I have read that some will wax the bushings but I'm hesitant to do that because I don't want to run the risk of getting wax transferred to the blank.

I'm going to test a couple blanks this weekend from the same piece of wood - one with walnut oil, one with BLO and one without anything but CA.

Has anyone else had any issues similar to this? Anyone else using walnut oil and CA without issue?

At about the same time I switched to using Mercury CA (thin and medium flex - M20FT and M300FM) and accelerator.

I've been happy overall with the finish I'm getting but I've had more issues since making this switch with the CA delaminating from the blank near the bushings.

Here's my process: turn the blank; sand up to 400; sand with 400 and walnut oil; let it set for at least 24 hours and then CA.

Typically I will do 4 coats of thin, 4 coats of medium and then 4 coats of thin. I'll also do some light sanding (600 grit) after each stage to keep the finish smooth and to get rid of any ridges that might show up. After that I'll micromesh and buff.

At different stages of applying CA I will snap the bushings off. For years this worked fine but after making the switch I started getting small chips delaminating from the blank - I could see raw wood.

I've tried scoring the blank/bushing joint with a razor blade but that hasn't always helped either. Last night as I was scoring the joint I could see the CA turn white (delaminating) on both the blank and the bushing as I was scoring it. When I took the bushings off the CA was flaking off of the bushing and I had a couple of places on the blank that had bare wood.

I'm wondering if the walnut oil is possibly a culprit - not getting good adhesion between the wood and CA.

This has happened with different species - walnut, leopardwood, osage orange.

I have read that some will wax the bushings but I'm hesitant to do that because I don't want to run the risk of getting wax transferred to the blank.

I'm going to test a couple blanks this weekend from the same piece of wood - one with walnut oil, one with BLO and one without anything but CA.

Has anyone else had any issues similar to this? Anyone else using walnut oil and CA without issue?