I'm finding that pens that have had even a month or two of steady use, are turning dull where the user's fingers grasp the barrel.

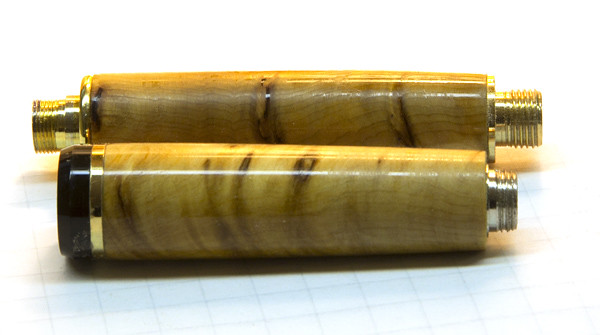

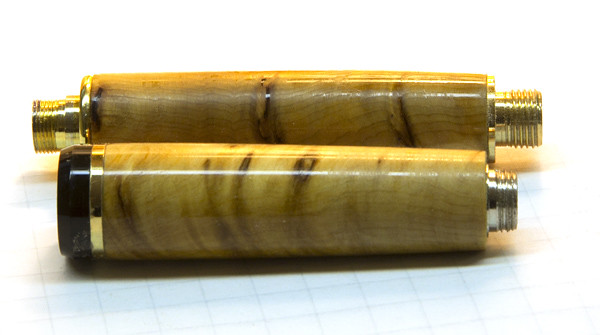

As an example, this is a Cigar in Yellow Cedar Burl -- it's a year or more old, and one that I used at work. You can see the worn areas -- it looks thrashed. I've had a number of people tell me that their finishes have faded like this.

This pen would have had between five and ten coats of CA, then buffed and hut polished. It had the usual CA glossy finish look ...

How long should a CA finish last? That is to say, how long should it stay uniformly glossy -- even where their fingers wrap around the barrel?

Thanks

Steve

Well, I still have some of my personal pens I made with CA finishes in early 2007 that show no wear whatsoever and the gloss is just the way it was then. My wife has carried the same Sierra pen in her purse also since early 2007 with no signs of wear either. Based on that, I would guess a CA finish is good for several years if treated half way decent.

I would like to add this and it is meant to have you think about possibilities rather than criticize so please take it in the spirit it is meant...............

This is based on meeting face to face with fellow turners during local chapter meetings and actually seeing how some apply finishes and how some buff.

To me a

COAT of CA means absolutely nothing! We read all the time where Joe puts on 8 coats of CA, Timmy puts on 12 coats of CA and Fred applies 25 coats. All these descriptions are meaningless because it's the final thickness that counts not the number of times one wipes on a drop of CA and while "rubbing it in" is actually wiping 95% of it back off and soaking it into the rag, cloth, paper towel or whatever he is using.

So let's say you managed to apply one ot two thousandths of an inch of CA film after all the COATS then take it to the buffer and while "Polishing" the blank you manage to buff of half the finish you had.

So what have you got, a blank with just enough CA to produce a marginal shine which may or may not have 100% coverage then it starts wearing off as your body oils and acids start eating away at it.

Your photos look like they may never have had a thick coating of CA to begin with so I might suggest a little experiment.

Sand a blank down and take very accurate measurements at certain points before you start applying your CA finish THEN apply as you normally would. When you think you have a good finish measure the blank again and see what you added. It might surprise you how little you actually managed to build up. THEN take it to the buffer and buff as usual THEN measure again, you may find that you hardly have .001" or .002" of a finish onor may have actualy buffed through the CA entirely and didn't notice. If I had to guess I would say most of my CA finishes are at least .005" thick with most running closer to .007". Not saying that's good, but I haven't had any finishes dull on me.