jskeen

Member

Was out in the shop taking some pictures for another post, and decided to snap these and toss them up here for comment.

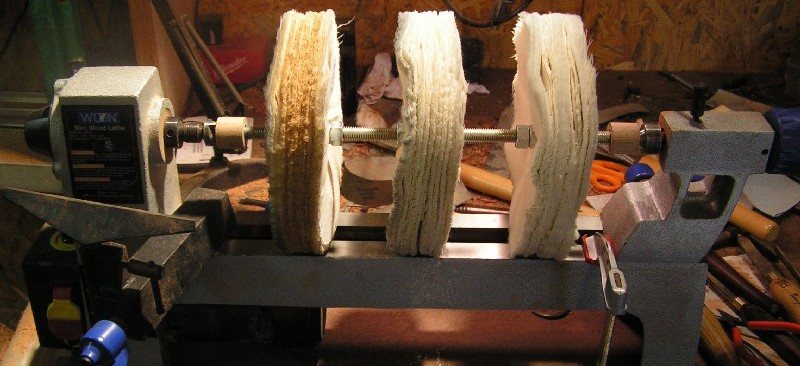

I think this thing cost me a total of about $19.00

I got the buffs from this guy on ebay, and they are totally awesome.

http://cgi.ebay.com/8-Buffing-Wheel...ryZ31485QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

Threaded right onto the 1/2" allthread, spun great, and almost no fluff or thread shedding right from the start. A great deal at $2.50 each. Anybody looking to make a buffer is highly recommended to order some. I wonder if they would work as replacements for beale buffs?

A few bucks of hardware from Home Labyrinth, 2 $1.95 ea buffing compound bars from sears hardware, a little can of renwax that has lasted me for 5 years or more for the third step, and i was ready to mount to my lathe.

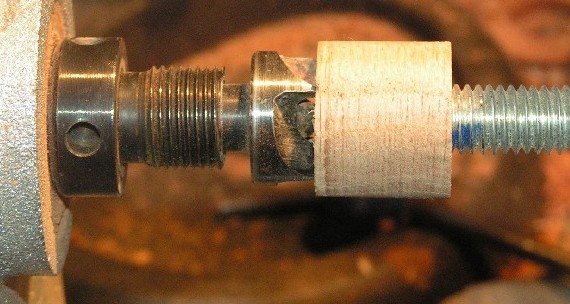

Cut these little bushings with a 1.5 inch hole saw, turned clean, drilled a 1/2" hole with a forstner bit, ground the ends of the allthread flat,and I was in business. There is a sweet spot for the tailstock end bushing that minimizes wobble and vibration that has to be marked and relocated each time, but the drive spur end is easy to put back in place

comments welcome

James

I think this thing cost me a total of about $19.00

I got the buffs from this guy on ebay, and they are totally awesome.

http://cgi.ebay.com/8-Buffing-Wheel...ryZ31485QQssPageNameZWDVWQQrdZ1QQcmdZViewItem

Threaded right onto the 1/2" allthread, spun great, and almost no fluff or thread shedding right from the start. A great deal at $2.50 each. Anybody looking to make a buffer is highly recommended to order some. I wonder if they would work as replacements for beale buffs?

A few bucks of hardware from Home Labyrinth, 2 $1.95 ea buffing compound bars from sears hardware, a little can of renwax that has lasted me for 5 years or more for the third step, and i was ready to mount to my lathe.

Cut these little bushings with a 1.5 inch hole saw, turned clean, drilled a 1/2" hole with a forstner bit, ground the ends of the allthread flat,and I was in business. There is a sweet spot for the tailstock end bushing that minimizes wobble and vibration that has to be marked and relocated each time, but the drive spur end is easy to put back in place

comments welcome

James