Mach4

Member

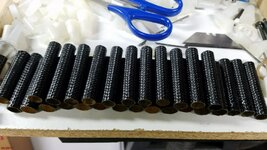

Just finished a successful no-cast carbon fiber pen. I've researched this site extensively and couldn't find anything other than casting for creating carbon fiber pens, so I believe this is an original technique/process (and would be pleased to be pointed to a link describing something similar). The technique involves using only CA as the finishing material.

I first prepare a custom pen tube out of aluminum with the same ID as the kit's brass tube and an OD .050 less than the finished target dimension. The tube is then black anodized (or painted if preferred or no anodizing available)

The custom tube is placed inside the 1/2" carbon fiber sleeve and stretched tight and straight. CA thin is applied liberally to ensure good adhesion to the tube and build up a good base coat. After curing, the ends are carefully trimmed flush with the end of the tube. It's then mounted on the mandrel using plastic finishing bushings.

CA medium is added in successive coats to build up a coating close to the final dimension. I run the CA on thick and use a nitrile gloved finger to spread and smooth using accelerator as desired. Allow curing, then the finish is sanded down to knock off the high points being careful to not contact the carbon. A sanding stick ensures getting a flat surface. Additional coats are applied and additional sanding until the surface is absolutely flat and the final dimension is achieved. The excess CA is carefully sanded off the ends of the tube to get a clean end.

From this point on a standard CA finishing regimen is employed. Wet sand to 1000 then MicroMesh to 12000 and PlastX and wax and assemble.

Here's the finished product - a Rollster Roller Ball in Gun Metal

I first prepare a custom pen tube out of aluminum with the same ID as the kit's brass tube and an OD .050 less than the finished target dimension. The tube is then black anodized (or painted if preferred or no anodizing available)

The custom tube is placed inside the 1/2" carbon fiber sleeve and stretched tight and straight. CA thin is applied liberally to ensure good adhesion to the tube and build up a good base coat. After curing, the ends are carefully trimmed flush with the end of the tube. It's then mounted on the mandrel using plastic finishing bushings.

CA medium is added in successive coats to build up a coating close to the final dimension. I run the CA on thick and use a nitrile gloved finger to spread and smooth using accelerator as desired. Allow curing, then the finish is sanded down to knock off the high points being careful to not contact the carbon. A sanding stick ensures getting a flat surface. Additional coats are applied and additional sanding until the surface is absolutely flat and the final dimension is achieved. The excess CA is carefully sanded off the ends of the tube to get a clean end.

From this point on a standard CA finishing regimen is employed. Wet sand to 1000 then MicroMesh to 12000 and PlastX and wax and assemble.

Here's the finished product - a Rollster Roller Ball in Gun Metal