robutacion

Member

Some time ago, I received a email with some advertising and in it, was these dark green (looked like lollies) resin/plastic (not sure yet) that was advertized as glow in the dark...!

Yes, they do glow in the dark from what I saw so, I though in ordering 1kg of them to try on pen blanks casting.

It took a long time to arrive but, when it did, I lost no time and using a single pen blank mold to test it out. My first problem was to work out how to position these beans in the mold and make them stay put. I thought of my kabob bamboo skewers to keep loose pieces together so, I started drilling them when I realise that, this material melts at low heat temps, as the drill bit was melting the stuff after a few rotations and get clogged with this melting stuff that wasn't easy to remove from the bit so, I decided to freeze a few I needed (7) and then drilled them without any dramas.

I noticed that each bean (95% of them) has air bubbles inside so, they were made with some sort of injecting mold that trapped air (obviously not designed properly) so, I decided to drill then through the centre, regardless if was up and down or sideways, this way I would remove most of the bubbles and all that area where the bamboo skewer is, would be removed/drilled at least 7mm so, that would take care of any other small bubbles, near by.

As for the resin to use, I knew that I had to use a semi-translucent powder to allow the glow to work so, I use one of the few "interference powders" that Pearlex makes, interference are their name for translucent, I used interference violet...!

The beans are touching each other but, due to their various shapes, the brass would be seen at certain places so, I couldn't make it too translucent but translucent enough to allow the beans to glow.

After I got the blank out of the mold, I decided to turn it round but I had the feeling that was still too early, the resin hadn't harden enough and at the blanks middle was a large bean that didn't allow that much resin around it so, without reinforcing it with a glued brass tube and turning it full lenght unsupported in between centres, was a big risk to the wobbles in the soft blank and forcing some separation between the resin and bean at the middle point.

Using the flap disk I manage to get it so size without any problems but, the more material I took, the more it start to wobble in the middle, and the separation I was concerned about did occur, not a full separation but enough movement between the 2 materials to keep breaking the surface of the CA layers, reason at the white hair line seen at the middle of the blank.

Not optimum but, good enough to allow me to take a few pics and see how much glow it would come through.

As I said previously, I only made this blank as a sample, I don't know why I keep bothering making these sort of blanks, when none of my woods are used when I have a train full of casting pieces in stock however, I have the glow beans that I can always use for something else but, if any of you like them and want some done, let me know...!

The only thing that I can saw is that, the bean material is a bit softer than I would like when you try to work it, even though they look pretty hard in your hand.

I can also say that, I'm not aware of many resin blanks out there that have glow in the dark pieces in its construction so, we can always say that, they look "different"...!:wink::biggrin:

What are your thoughts...???

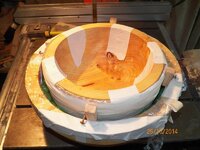

PS: I just noticed that, I have no pics of the beans kabob but, the first pic, is another way I thought in making the blanks skeleton to put in the mold, I used thick CA

and accelerator to position the beans on top of each other but, I endup not using it in the end...!

Cheers

George

Yes, they do glow in the dark from what I saw so, I though in ordering 1kg of them to try on pen blanks casting.

It took a long time to arrive but, when it did, I lost no time and using a single pen blank mold to test it out. My first problem was to work out how to position these beans in the mold and make them stay put. I thought of my kabob bamboo skewers to keep loose pieces together so, I started drilling them when I realise that, this material melts at low heat temps, as the drill bit was melting the stuff after a few rotations and get clogged with this melting stuff that wasn't easy to remove from the bit so, I decided to freeze a few I needed (7) and then drilled them without any dramas.

I noticed that each bean (95% of them) has air bubbles inside so, they were made with some sort of injecting mold that trapped air (obviously not designed properly) so, I decided to drill then through the centre, regardless if was up and down or sideways, this way I would remove most of the bubbles and all that area where the bamboo skewer is, would be removed/drilled at least 7mm so, that would take care of any other small bubbles, near by.

As for the resin to use, I knew that I had to use a semi-translucent powder to allow the glow to work so, I use one of the few "interference powders" that Pearlex makes, interference are their name for translucent, I used interference violet...!

The beans are touching each other but, due to their various shapes, the brass would be seen at certain places so, I couldn't make it too translucent but translucent enough to allow the beans to glow.

After I got the blank out of the mold, I decided to turn it round but I had the feeling that was still too early, the resin hadn't harden enough and at the blanks middle was a large bean that didn't allow that much resin around it so, without reinforcing it with a glued brass tube and turning it full lenght unsupported in between centres, was a big risk to the wobbles in the soft blank and forcing some separation between the resin and bean at the middle point.

Using the flap disk I manage to get it so size without any problems but, the more material I took, the more it start to wobble in the middle, and the separation I was concerned about did occur, not a full separation but enough movement between the 2 materials to keep breaking the surface of the CA layers, reason at the white hair line seen at the middle of the blank.

Not optimum but, good enough to allow me to take a few pics and see how much glow it would come through.

As I said previously, I only made this blank as a sample, I don't know why I keep bothering making these sort of blanks, when none of my woods are used when I have a train full of casting pieces in stock however, I have the glow beans that I can always use for something else but, if any of you like them and want some done, let me know...!

The only thing that I can saw is that, the bean material is a bit softer than I would like when you try to work it, even though they look pretty hard in your hand.

I can also say that, I'm not aware of many resin blanks out there that have glow in the dark pieces in its construction so, we can always say that, they look "different"...!:wink::biggrin:

What are your thoughts...???

PS: I just noticed that, I have no pics of the beans kabob but, the first pic, is another way I thought in making the blanks skeleton to put in the mold, I used thick CA

and accelerator to position the beans on top of each other but, I endup not using it in the end...!

Cheers

George

Attachments

Last edited: