Ok, let's look at all the pictures you posted (numbered versions below):

Pictures 2-4, and 13 are different versions of the same thing: a thumbnail gouge sharpener.

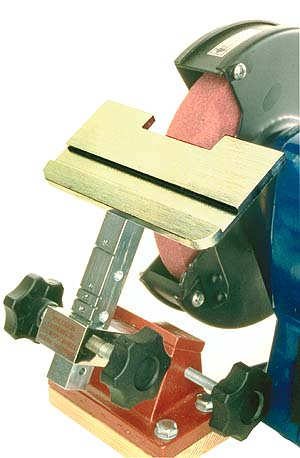

Pictures 1, 6, 15, 16 are all different versions of the same thing: an arm rest for sharpening things with a fixed angle. Although 16 is a home-brew for sharpening on a belt sander rather than a wheel.

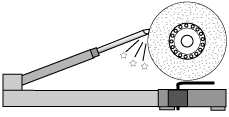

Pictures 7, 9, 11, and 12 are all different versions of the same thing: an arm with fixed base for sharpening spindle gouges. Although item 12 also has an offset to the fixed base for sharpening skews.

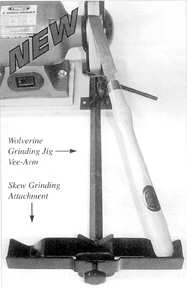

Item 10-13 are various pieces of the Wolverine system (that combines all of the above), some showing it in use.

Item 5 is the lower arm of item 6.

Item 8 is who knows what?

So, everything you have shown are bits and pieces of various systems to be used with a 3rd-party vertical grinding wheel (preferably of large diameter and slow speed (and even more so, wet)) to be able to sharpen most of your woodworking tools. Because they are all used for different kinds of tools it isn't an either/or situation and therefore isn't as complicated as you think.

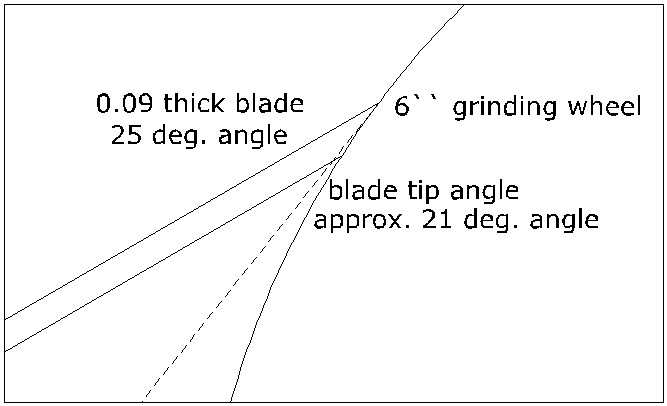

The real "confusion" comes from what sharpening "wheel" to use. I think it is safe to say that the consensus is that a large diameter, wet wheel is your best choice for ease and keeping your tools tempered. You can (and I do) use my sanding disk to sharpen many of your tools but you have to be VERY careful to not overheat the tool and it is very tough to get sharpening jigs to work on it (as demonstrated by picture 16 which is quite a concoction and will only work for one kinda tool).

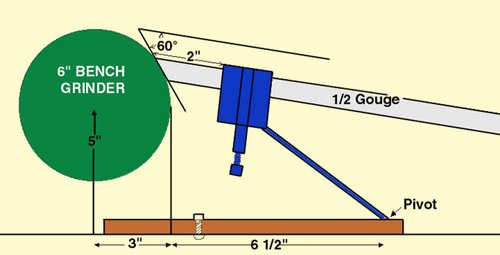

If you are going to go with a vertical wheel setup, in general you want a extendable arm so you can adjust the length so that the angle of your tool grind matches up with the wheel. 7, 9-12 all show various versions including what looks like a home made one.

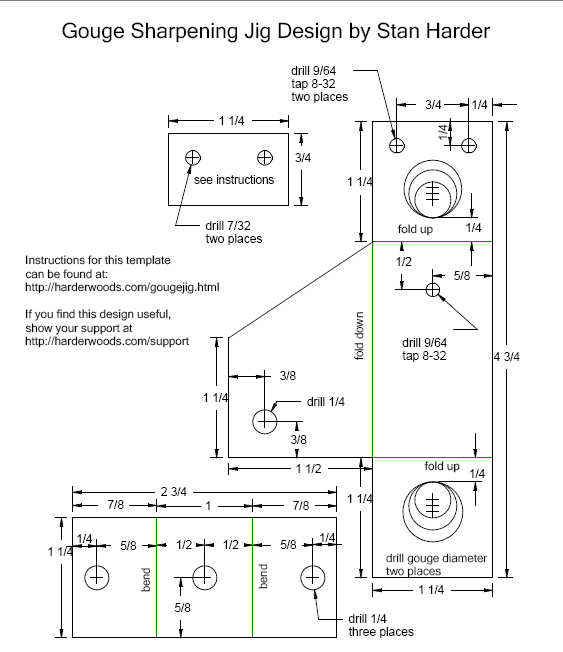

You also want something that will let you do the complex grind of the fingernail gouges: 2-4 and 13. This will sit into the "nook" on your extendable arm and will let you easily replicate the complex curves every time.

Lastly you want the simple flat fixed plate to do chisels and simple tools like roughing gouges: 1, 6, and 15. It just needs to be very sturdy.

All of the above can be home made for a lot less than purchasing complete systems but the complete system from someone like Wolverine makes it really easy.

Now, if you buy a Jet or Tormek rather than a simple grinding wheel system, then none of what you are seeing will work but there are equivalent jigs for those systems. The benefit to the Jet and Tormek are the large wheel so your tools don't end up very concave; slow turning and wet so the tool stays cool. Is it worth the money? I'm arguing with myself about that right now. I have a 6" grinder that proved to be way to small and too fast the first time I used it so I bought a 2-speed 8" grinder and new wheels and a wolverine system. It works well for some of the tools but for some I have gone to my sanding disk to get the edges I need and jigs for that. Hmmmmm I bet I coulda bought the Jet for all the money I've spent on other (arguably lesser) systems.

I hope that helps!

GK

Originally posted by palmermethod

<br />As a newbie buying/building my penturning equipment, I want to make my own grinding jig(s). As one expert turner remarked, "once you understand the principle build a jig to make it work". I followed that advice and started planning the jig. First I Google'd some pix of Gouge Jigs.

Whoa! There are a _Bunch_ of different ways to approach the design. ALL of them look excellent. I'm not sure which type is best for me since I don't plan on selling my stuff. Just a hobby for a retired guy.

Anyway here are some pix. Hope they are of some help.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16