I just finished making a successful closed ended click pen, but it was not easy. But if you use the whole kit I think it could be simpler.

OK here goes nothing.

The parts. 1 click mech, various sized old tubes, 1 x 16mm stainless thread, small piece of aluminium. etc. Not shown but needed, I found out later, is the normal tube connector from the click pen kit.

Next is to fit the clickmech in the tube. I crimped the end of the tube slightly to stop the mech pulling out. The normal button is cut short and a piece of aluminium was used to make a bush to fit the next tube.

Next is to fit the next tube over the first. This must be a slip fit on the first tube and a press fit on the aluminium. It will be cut much shorter.

Now I temp fit the kit nib and refill to check it still works.

You could of course stop there and build the standard pen, but I wanted a stainless nib. This is where I remembered that to change the refill on the kit, you simply unscrewed the nib. But my nib was going to be press fitted or glued.

Adding the normal coupler from a standard click pen was a simple case of cutting the tube and pressing it in. Of course the part that form the cb was just turned flush with the tube. In the next pic you can see that the outer tube has been shortened.

Nearly forgot to post this pic. Here you can see the smallest tube that acts as a spacer to stop the click mech from being pushed in. This was just cut shorter once the connector was installed.

As the plunger button spins freely and will be used to hold the body, I had to make a lock so that I could unscrew the coupler. I simply used a piece of tube with a 'v' on it and put a corresponding 'notch' on the plunger button end.

Getting the 'v' piece in the correct place is achieved by holding it in place with tape till it works, then fix it with CA

Here I check it all still works perfectly. The mech must operate irrispective of where the button is. The 'v' will engage when the button is fully pressed to take all the spring slack and then rotated to unlock.

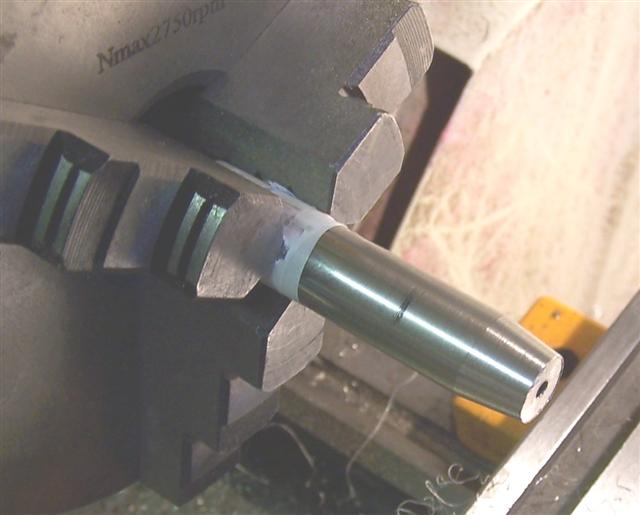

Next is to taper the nib, but first the one end should be polished. DAMHIKT[:I] I don't have a pic of drilling the holes in the nib, but here you can see the big one that the blank will plunge into. This one is 11.5mm dia. The outside diameter of the nib is 13mm. The hole is about 15mm deep.

All that is left to do is shape the nib to you desired shape and cut the blank to suite.

This is what I came up with. I dislike the glitter blank and am going to change it to one of PR Princess' cool blanks real soon!!!!

Hope someone finds this useful

OK here goes nothing.

The parts. 1 click mech, various sized old tubes, 1 x 16mm stainless thread, small piece of aluminium. etc. Not shown but needed, I found out later, is the normal tube connector from the click pen kit.

Next is to fit the clickmech in the tube. I crimped the end of the tube slightly to stop the mech pulling out. The normal button is cut short and a piece of aluminium was used to make a bush to fit the next tube.

Next is to fit the next tube over the first. This must be a slip fit on the first tube and a press fit on the aluminium. It will be cut much shorter.

Now I temp fit the kit nib and refill to check it still works.

You could of course stop there and build the standard pen, but I wanted a stainless nib. This is where I remembered that to change the refill on the kit, you simply unscrewed the nib. But my nib was going to be press fitted or glued.

Adding the normal coupler from a standard click pen was a simple case of cutting the tube and pressing it in. Of course the part that form the cb was just turned flush with the tube. In the next pic you can see that the outer tube has been shortened.

Nearly forgot to post this pic. Here you can see the smallest tube that acts as a spacer to stop the click mech from being pushed in. This was just cut shorter once the connector was installed.

As the plunger button spins freely and will be used to hold the body, I had to make a lock so that I could unscrew the coupler. I simply used a piece of tube with a 'v' on it and put a corresponding 'notch' on the plunger button end.

Getting the 'v' piece in the correct place is achieved by holding it in place with tape till it works, then fix it with CA

Here I check it all still works perfectly. The mech must operate irrispective of where the button is. The 'v' will engage when the button is fully pressed to take all the spring slack and then rotated to unlock.

Next is to taper the nib, but first the one end should be polished. DAMHIKT[:I] I don't have a pic of drilling the holes in the nib, but here you can see the big one that the blank will plunge into. This one is 11.5mm dia. The outside diameter of the nib is 13mm. The hole is about 15mm deep.

All that is left to do is shape the nib to you desired shape and cut the blank to suite.

This is what I came up with. I dislike the glitter blank and am going to change it to one of PR Princess' cool blanks real soon!!!!

Hope someone finds this useful