truckerdave

Member

I am extremely frustrated by my results with bowl turning!!!

If one more bowl blank flies off my chuck, I will get rid of ALL my tools!!!

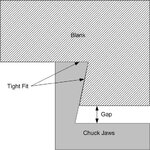

I have started with round bowl blanks of about 6" in diameter. I have tried using a screw chuck and also a blank screwed to a faceplate. I seem to be able to shape the outside profile to my liking, I turn a 2" recess about 1/4" to 3/8" deep with dovetail shape to match the jaws to grip better. Then using a Nova chuck, I mount the blank on the bottom. It doesn't take long for the blank to come flying off the chuck.

I have sharpened my bowl gouge satisfactorily. I can tell by the shavings coming off the wood. I use a VERY light touch, rubbing the bevel, everything I have been taught. Then without warning, the damn thing goes flying!

I have had the wood spilt along the grain or just plain fly off the chuck.

Please let me know what I am doing wrong before I sell all my tools and find an easier hobby!!!

:at-wits-end:

If one more bowl blank flies off my chuck, I will get rid of ALL my tools!!!

I have started with round bowl blanks of about 6" in diameter. I have tried using a screw chuck and also a blank screwed to a faceplate. I seem to be able to shape the outside profile to my liking, I turn a 2" recess about 1/4" to 3/8" deep with dovetail shape to match the jaws to grip better. Then using a Nova chuck, I mount the blank on the bottom. It doesn't take long for the blank to come flying off the chuck.

I have sharpened my bowl gouge satisfactorily. I can tell by the shavings coming off the wood. I use a VERY light touch, rubbing the bevel, everything I have been taught. Then without warning, the damn thing goes flying!

I have had the wood spilt along the grain or just plain fly off the chuck.

Please let me know what I am doing wrong before I sell all my tools and find an easier hobby!!!

:at-wits-end: