Hey all,

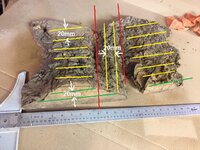

Still new to the forum so hopefully I'm not posting in the wrong spot, but I was given a piece of Burl that was harvested in the 1930s. A couple questions: I was going to try to make some pen blanks out of it - any tips or anything I should be aware of?

Also, can anyone identify the wood? I think it might be red oak based on the one picture from harvesting the Burl, but not sure if anyone could tell just from the Burl? I could probably post a couple more pics later.

Thanks!

Eric

Sent from my iPhone using Penturners.org mobile app

Still new to the forum so hopefully I'm not posting in the wrong spot, but I was given a piece of Burl that was harvested in the 1930s. A couple questions: I was going to try to make some pen blanks out of it - any tips or anything I should be aware of?

Also, can anyone identify the wood? I think it might be red oak based on the one picture from harvesting the Burl, but not sure if anyone could tell just from the Burl? I could probably post a couple more pics later.

Thanks!

Eric

Sent from my iPhone using Penturners.org mobile app