thewishman

Member

Trying to figure out how to powder coat a bunch of brass tubes (hundreds). Could I use the Christmas ornament hooks to hang the brass from my toaster oven rack?

Buy a used full size oven on CL.

John could you show a picture of your setup, I am a little slow in visualizing it.

Your links are broke. Now I have to search for the information myself. Darn it.

Does the powder coating process generate a lot of bad smell? Can I do it in my basement?

John could you show a picture of your setup, I am a little slow in visualizing it.

Your links are broke. Now I have to search for the information myself. Darn it.

Does the powder coating process generate a lot of bad smell? Can I do it in my basement?

Your links are broke. Now I have to search for the information myself. Darn it.

Does the powder coating process generate a lot of bad smell? Can I do it in my basement?

Okay, let me rephrase. I want to PC a BUNCH of tubes quickly, would the little Christmas ornament hooks conduct enough of the charge to powdercoat the brass tubes? I'd hang 25 or so from a toaster oven rack and do several batches. Would a set-up like that work?

I can clean up the insides with a big round file a lot quicker than putting foil inside each tube.

John,

I was in a Harbor Freight store on Wednesday and looked at the powder coating units.

They still carry some type of one for $70.00 and if someone wants one an can get a 20% of coupon, they would run $56.00.

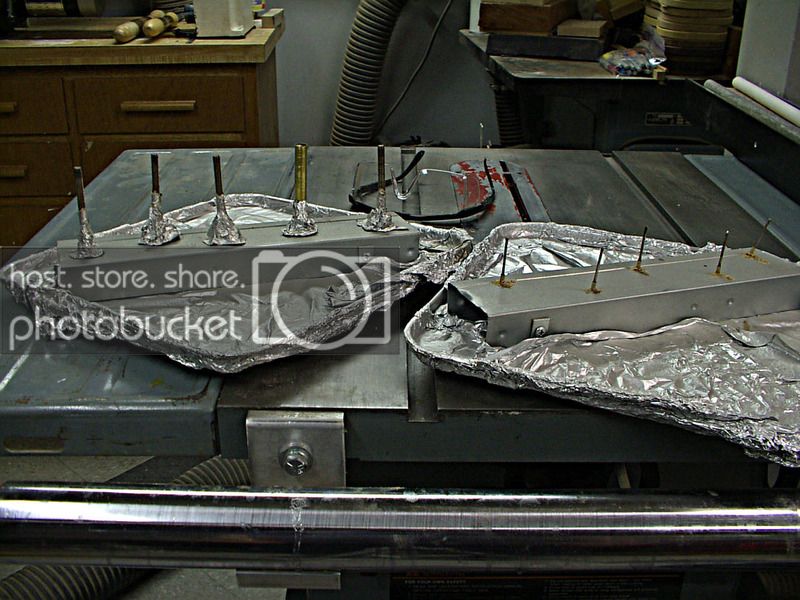

I had forgotten all about this video!This is my yet to be tested solution.

I wanted something that was low profile that could fit into an toaster oven so I used a cheese grader. No hole drilling, easily adjustable for number and sizes of tubes, and all metal. All I needed were nuts and bolts.

This was based on a great video by Seamus.

https://www.youtube.com/watch?v=K-feQO6Ygv0