jttheclockman

Member

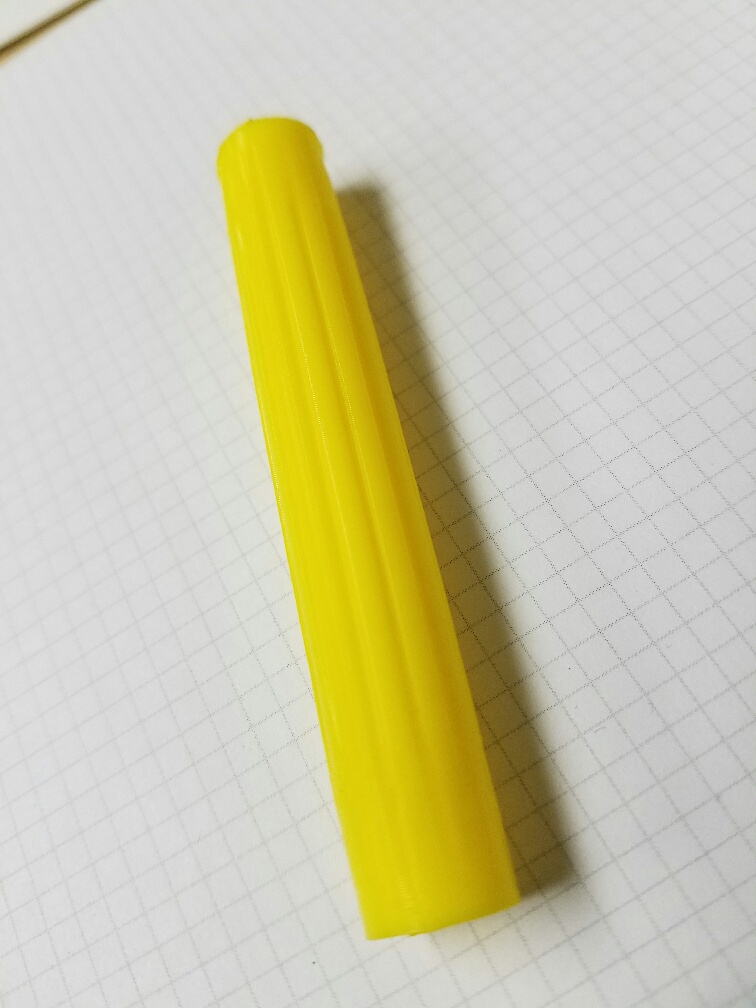

Was thinking the other day and ran into some articles or ads from Micromark about their new line of 3D printers. It got me to thinking are we that much closer to seeing 3D printer made pens. Maybe 3D printer blanks that can have a ton new designs.

We have the ability now to use routers, lasers and cnc machines to make cutouts and infills, but how about taking it to the next step and having the entire blank done by the press of a button.

Any thoughts????

We have the ability now to use routers, lasers and cnc machines to make cutouts and infills, but how about taking it to the next step and having the entire blank done by the press of a button.

Any thoughts????