Rockytime

Member

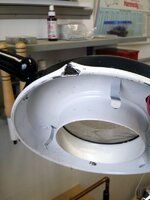

Yesterday I was using a Nova G3 chuck which I had purchases used. It had a slight bind and disassembled it to work out the bind. I put in on the spindle and turned on the power at 3950 rpm. There was a flash of light and a huge explosion. The jaws came out of the chuck. After gathering my wits I went looking for the missing jaws. I found all but one. After sweeping and crawling around on the floor I finally gave up. While sitting at the lathe and contemplating my next move I noticed a hole in the wall behind the lathe. Now I know where jaw is. I will try to fish it out with some rare earth magnets other wise I will have to remove some 5/8" drywall. The reason soon became obvious. When replacing the snap ring I had not seated it all the way allowing the scroll to back off the jaws and send them flying. I have worked on scroll chucks for 30 years and then finally a stupid mistake. I am forever grateful my head was not two inches closer to the head stock. However all is well.