Terry Kester

Member

So I am going to try and do some segmenting work. Seems the best advice is to bore the hole in the blank FIRST, cut the segments, dry fit and then do glue-up. (At least for the design I'm looking at)

Here's the thing. I would prefer to use wood glue (Titebond 3) to glue up my segments and not use CA as I see some do, where they fastening the blank to the tube as you go. (Hopefully won't start a war on which glue is best for gluing tubes)

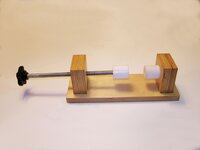

I would like to use a tube (or bolt or ?) just to keep things in line as I assemble and glue using Titebond, then REMOVE that tube or bolt or whatever and then insert the permanent tube later using 2 part epoxy.

Anyone else do anything like this? Any dangers to avoid with getting the tube or bolt stuck by the wood glue? Would I be making a huge mistake for the epoxy adhesion later to Wax the tube or bolt first to keep the wood glue from sticking to it? Am I crazy and being stupid?

Thank you

Terry

Here's the thing. I would prefer to use wood glue (Titebond 3) to glue up my segments and not use CA as I see some do, where they fastening the blank to the tube as you go. (Hopefully won't start a war on which glue is best for gluing tubes)

I would like to use a tube (or bolt or ?) just to keep things in line as I assemble and glue using Titebond, then REMOVE that tube or bolt or whatever and then insert the permanent tube later using 2 part epoxy.

Anyone else do anything like this? Any dangers to avoid with getting the tube or bolt stuck by the wood glue? Would I be making a huge mistake for the epoxy adhesion later to Wax the tube or bolt first to keep the wood glue from sticking to it? Am I crazy and being stupid?

Thank you

Terry