BackyardSmokin

Member

Sorry if something similar was posted before. I have searched but not able to find anything.

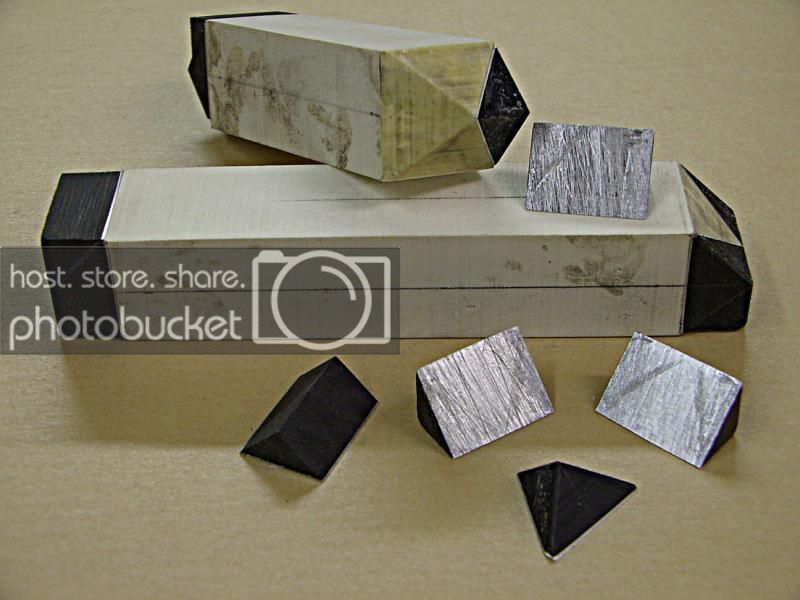

I am creating a blank for a Sierra pen that will have the Jamaican flag made out of acrylic and then some stabilized Blue Mahoe on each side. I will be starting the blank as a 3/4 square before turning.

The Jamaican flag is a yellow X with green on top/bottom and black on the sides. I was thinking of stacking a yellow blank on top of either the black or green blanks then cutting both at the same time for the respective areas. Will this work or is there a better way cut them so they match?

When it comes to finishing, I have reactions to CA so using that is out. I usually use Pen Plus for wood and wet sanding/novus for acrylic. Can I tape off the acrylic and finish the wood then vice versa to finish the acrylic? Is there another way to get a consistent finish without using CA?

Thanks in advance.

I am creating a blank for a Sierra pen that will have the Jamaican flag made out of acrylic and then some stabilized Blue Mahoe on each side. I will be starting the blank as a 3/4 square before turning.

The Jamaican flag is a yellow X with green on top/bottom and black on the sides. I was thinking of stacking a yellow blank on top of either the black or green blanks then cutting both at the same time for the respective areas. Will this work or is there a better way cut them so they match?

When it comes to finishing, I have reactions to CA so using that is out. I usually use Pen Plus for wood and wet sanding/novus for acrylic. Can I tape off the acrylic and finish the wood then vice versa to finish the acrylic? Is there another way to get a consistent finish without using CA?

Thanks in advance.