You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

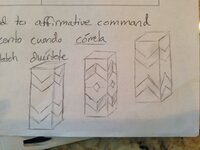

How do you make this???

- Thread starter Chewy3939

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Cmiles1985

Member

I believe there is a tutorial in the library on making a "herringbone" blank. That's about what your photo looks like. Then cut in half or fourths and alternate the pieces. Does that make sense?

Displaced Canadian

Member

To get that particular design you need to make a herring bone 360.

Sent from my phone using some program

Sent from my phone using some program

Joe S.

Member

actually I don't think that's a herringbone...

My thought: segment thin stock to look similar to the colorgrain type blanks at an angle, slice it into 4 parts and alternate the way they slant and glue that up. That should get you something like that blank.

My thought: segment thin stock to look similar to the colorgrain type blanks at an angle, slice it into 4 parts and alternate the way they slant and glue that up. That should get you something like that blank.

Glue up 3/4 x 1/8th in strips 10-12 inches long. Shorter may work until you have a 10x5-6 inch block. set your miter gage on your saw to 15 degrees or what ever you like. That will cut the block on an angle. Decide on how many panels you want and divide that number into 360. Set your saw blade angle at that answer. Cut off the end waste, flip it end for end, front to back after each pass. Not left to right. glue up the wedges.

bjbear76

Member

Glue up 3/4 x 1/8th in strips 10-12 inches long. Shorter may work until you have a 10x5-6 inch block. set your miter gage on your saw to 15 degrees or what ever you like. That will cut the block on an angle. Decide on how many panels you want and divide that number into 360. Set your saw blade angle at that answer. Cut off the end waste, flip it end for end, front to back after each pass. Not left to right. glue up the wedges.

Right! Just as simple as that! :hypnotized: LOL

He may have set his miter gage at 30 degrees judging by the angle of the pieces.

You could get pretty close to that pattern with a router....

I've done loads of zigzag designs with a small router in my toolpost and using the lathe as the indexer.

I reckon that the main tool used here was a decent tablesaw though.

I must admit that that actual pen does look pretty cool!! Any idea if it was someone here that made it? I'd like to see more of his/her work.

I've done loads of zigzag designs with a small router in my toolpost and using the lathe as the indexer.

I reckon that the main tool used here was a decent tablesaw though.

I must admit that that actual pen does look pretty cool!! Any idea if it was someone here that made it? I'd like to see more of his/her work.

LarryDNJR

Member

Matt, here's how I do it these days.

KenV

Member

Matt -- that appears to be 12 piece stave construction - a pretty standard segmented turning construction technique. The design is probably table saw based, but could have been done with a sliding miter saw. Some of the better segmented turners use the Festool sliding saw because of its tight tolerance. The thickness could have been quite a bit thicker to facilitate handling and gluing the staves, and would have been turned away. Could have been cut with a Byrnes precision saw too.

The strips are very well matched for thickness and the glueup is excellent. The meeting of the points is dependent on precision in the thickness and tight control of the glueup.

Tibbett's Book on segmented woodturning is a good starting point for staved segmentation.

The strips are very well matched for thickness and the glueup is excellent. The meeting of the points is dependent on precision in the thickness and tight control of the glueup.

Tibbett's Book on segmented woodturning is a good starting point for staved segmentation.