No pictures because I wasn't terribly happy with the final pen, but I had to attempt the blank 3 times. The first 2 attempts were a pau ferro blank with off-white corian scallops and an aluminum paint can lid as a thin metal liner.

I used 5 minute epoxy to glue everything together, but it just never seemed to hold. I think I made several mistakes, including rushing the glue-up before drilling the first blank and then rushing the drilling on the 2nd blank. I think I got the blank too hot which softened the epoxy.

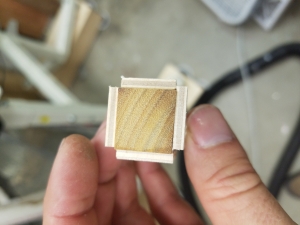

For my final blank, I used wood for the scalloped segments, so I was able to use CA to glue everything up and it worked much better. It just wasn't the final scheme I was after.

So there ya go. Any pointers you can offer for prep, adhesives, etc for using materials other than woods for segments are all welcomed.

I used 5 minute epoxy to glue everything together, but it just never seemed to hold. I think I made several mistakes, including rushing the glue-up before drilling the first blank and then rushing the drilling on the 2nd blank. I think I got the blank too hot which softened the epoxy.

For my final blank, I used wood for the scalloped segments, so I was able to use CA to glue everything up and it worked much better. It just wasn't the final scheme I was after.

So there ya go. Any pointers you can offer for prep, adhesives, etc for using materials other than woods for segments are all welcomed.