Ted Sachs

Member

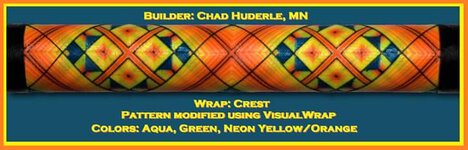

I've been making pens for about four months now and just started casting blanks from the tubes I wrap with thread. I used my old rod wrapping techniques that I used making custom fishing rods from over thirty years ago. I dusted off my rod wrapping hobby to try and combine it with pen making. I have the wrapping part and the differences from rods to pens worked out now, but the casting is still giving me problems with about a fifty percent success rate. That's way less than desirable after spending a minimum of eight hours wrapping to see it ruined when I cast it. Some of the ones I wrap take as much as sixteen hours of wrapping. The Black Widow pen being one of those. Two tubes with a hard pattern to wrap makes it heartbreaking to see the cast go awry.

Here's some pics of what I'm trying to get done. So far I've found that I have to coat it all in epoxy brushed on before casting or the thread will create bubbles like you've never seen. It's been a slow learning process, but I'm getting there. All of these were done using PR I bought from Hobby Lobby.

Here's some pics of what I'm trying to get done. So far I've found that I have to coat it all in epoxy brushed on before casting or the thread will create bubbles like you've never seen. It's been a slow learning process, but I'm getting there. All of these were done using PR I bought from Hobby Lobby.