Has anyone seen an attachment photo or video for attaching a DRO to the "X" axis? In the Library, or anywhere else?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"X" axis DRO

- Thread starter joefyffe

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

bluwolf

Member

Joe,

The X axis is probably the easiest one to do. A couple of tapped holes on the back of the crosslide for a bracket down to the reader. Then a couple of tapped holes at the ends of the scale. Maybe a couple of spacers at the mounting ends of the scale to get the travel level. Now the Y axis, that's a different story, always a compromise...

Mike

The X axis is probably the easiest one to do. A couple of tapped holes on the back of the crosslide for a bracket down to the reader. Then a couple of tapped holes at the ends of the scale. Maybe a couple of spacers at the mounting ends of the scale to get the travel level. Now the Y axis, that's a different story, always a compromise...

Mike

bluwolf

Member

Okay, having thought about it some more.... it dawned on me that you might be using the correct axis designations rather than the commonly used ones. The correct ones being Z for the longitudinal, and X for the crosslide. So, if you're using the correct ones never mind what I just said :biggrin:

:biggrin:

Mike

Mike

O.K. I'll never mind!Okay, having thought about it some more.... it dawned on me that you might be using the correct axis designations rather than the commonly used ones. The correct ones being Z for the longitudinal, and X for the crosslide. So, if you're using the correct ones never mind what I just said:biggrin:

Mike

Dalecamino

Local Chapter Leader

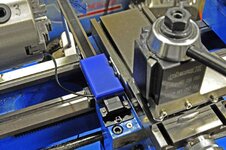

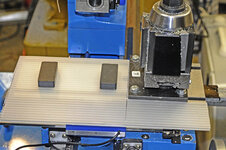

Congratulations Joe. Looks like you did a nice job there.

cnirenberg

Member

Joe,

Looks great. Anything special to look out for when doing the cross slide install, other than making sure its fits well?

Looks great. Anything special to look out for when doing the cross slide install, other than making sure its fits well?

Joe,

Looks great. Anything special to look out for when doing the cross slide install, other than making sure its fits well?

No, I just made a bracket to fit on the bottom of the reader, and as you can see, there isn't much sticking up, in order to stay even with the top of the slide. I drilled and taped for 6X32

bluwolf

Member

Looks nice, clean and straightforward. No clearance issues under the chuck when the jaws are open? You also might want to think about some kind of cover. If oil or swarf get on the scale and in the reader, it's not going to work for long.

Mike

Mike

Looks nice, clean and straightforward. No clearance issues under the chuck when the jaws are open? You also might want to think about some kind of cover. If oil or swarf get on the scale and in the reader, it's not going to work for long.

Mike

Mike: I think the only time I will have clearance issues is if and when I use the four jaw chuck. And THANKS for the heads up on the cover.

Dalecamino

Local Chapter Leader

A little pen kit baggie works pretty well.Looks nice, clean and straightforward. No clearance issues under the chuck when the jaws are open? You also might want to think about some kind of cover. If oil or swarf get on the scale and in the reader, it's not going to work for long.

Mike

Mike: I think the only time I will have clearance issues is if and when I use the four jaw chuck. And THANKS for the heads up on the cover.

Mapster

Member

Very simple, yet effective design. I like it! I may have to look into doing something similar on mine. Nice Enco lathe by the way, I really like the blue and the blue dro's

bluwolf

Member

A little pen kit baggie works pretty well.Looks nice, clean and straightforward. No clearance issues under the chuck when the jaws are open? You also might want to think about some kind of cover. If oil or swarf get on the scale and in the reader, it's not going to work for long.

Mike

Mike: I think the only time I will have clearance issues is if and when I use the four jaw chuck. And THANKS for the heads up on the cover.

Chuck, I wasn't referring to the display. I meant a cover over the scale and reader. Where it's mounted there in the front of the crosslide, is where a lot of crap falls while working on the lathe.

Joe, the cover can be something as simple as aluminum roof flashing. It's not real high tech looking. But it's simple to bend, doesn't take up a lot of room and it's light so it can be held on with something as simple as a couple magnets. That way you don't have to drill and tap a bunch of holes to hold it on. The magnets also makes things simple when you find your first cover design runs into something or another and you have to re-do it:biggrin:

Mike

A little pen kit baggie works pretty well.Looks nice, clean and straightforward. No clearance issues under the chuck when the jaws are open? You also might want to think about some kind of cover. If oil or swarf get on the scale and in the reader, it's not going to work for long.

Mike

Mike: I think the only time I will have clearance issues is if and when I use the four jaw chuck. And THANKS for the heads up on the cover.

Chuck, I wasn't referring to the display. I meant a cover over the scale and reader. Where it's mounted there in the front of the crosslide, is where a lot of crap falls while working on the lathe.

Joe, the cover can be something as simple as aluminum roof flashing. It's not real high tech looking. But it's simple to bend, doesn't take up a lot of room and it's light so it can be held on with something as simple as a couple magnets. That way you don't have to drill and tap a bunch of holes to hold it on. The magnets also makes things simple when you find your first cover design runs into something or another and you have to re-do it:biggrin:

Mike

Mike: I guess great minds DO run together!!